Fully variable electro-hydraulic valve system

A valve and variable technology, applied in the direction of non-mechanical actuated valves, engine components, machines/engines, etc., can solve problems such as constant crankshaft angle, oil loss, and affecting the normal operation of the system to achieve fast response and control convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

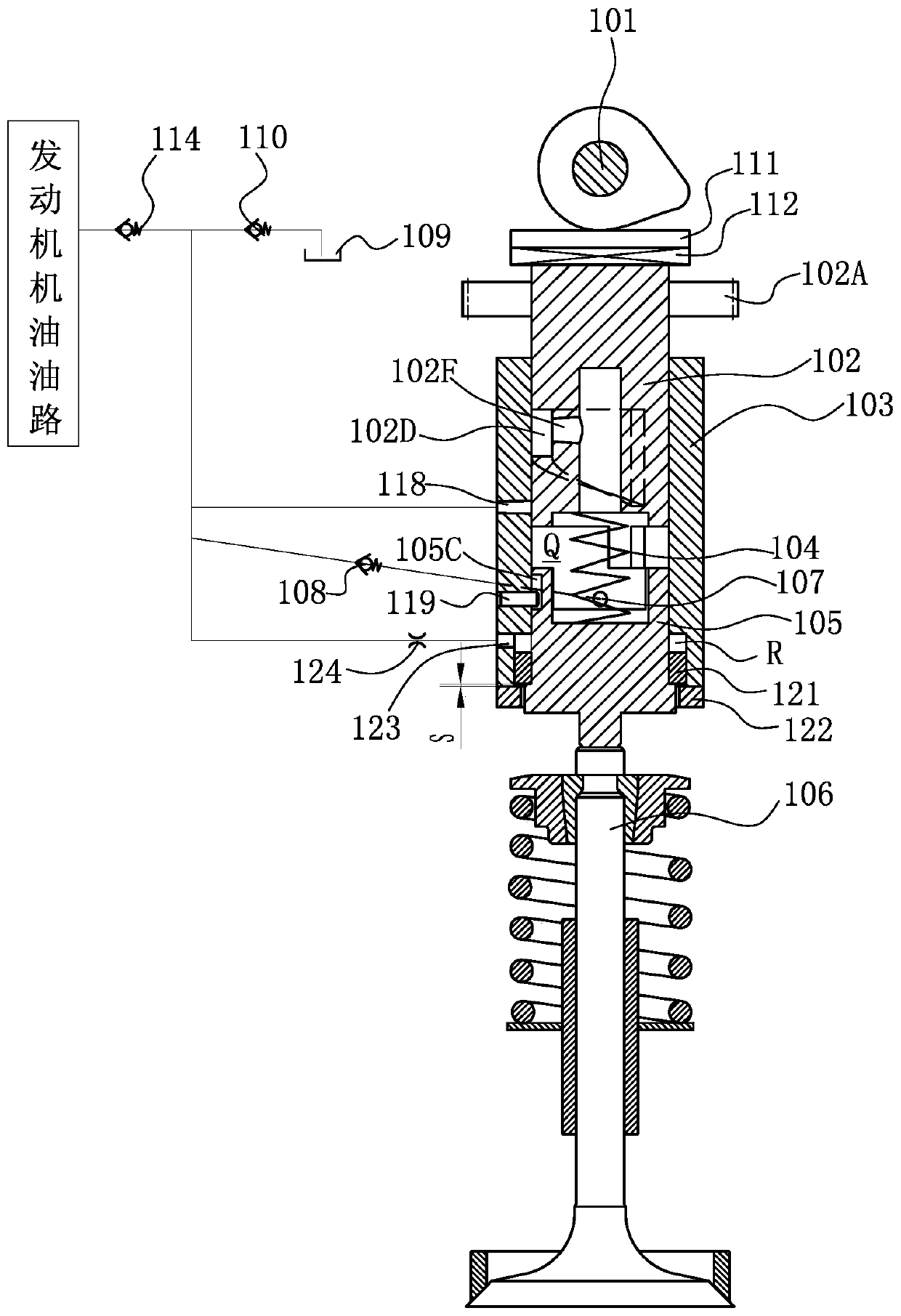

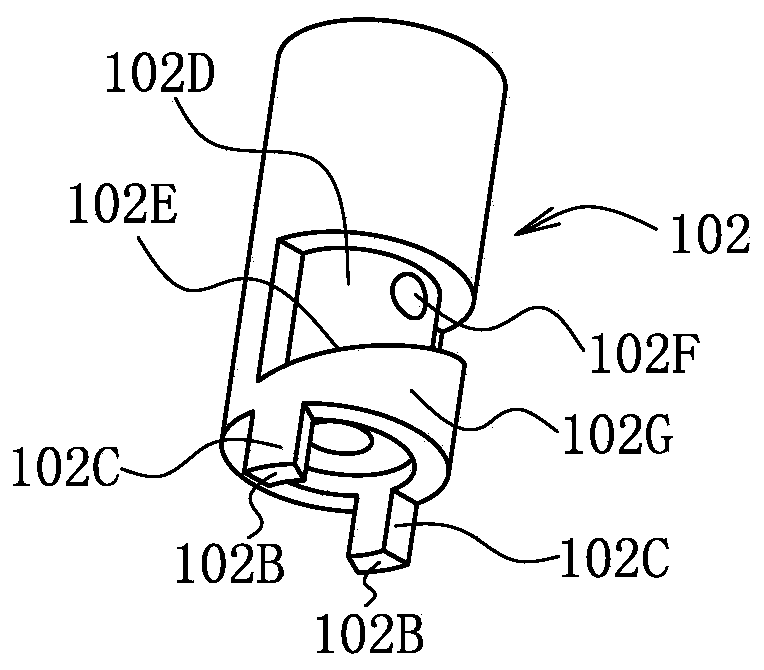

[0035] Such as figure 1 As shown, a fully variable electro-hydraulic valve system, the sliding sleeve 103 is fixed relative to the engine, the screw shaft 102 and the piston 105 are respectively in sliding and sealing connection with the sliding sleeve 103, and the screw shaft 102 is controlled by the direction of the camshaft 101 in the axial direction. The piston 105 abuts against the valve assembly 106 on the cam surface.

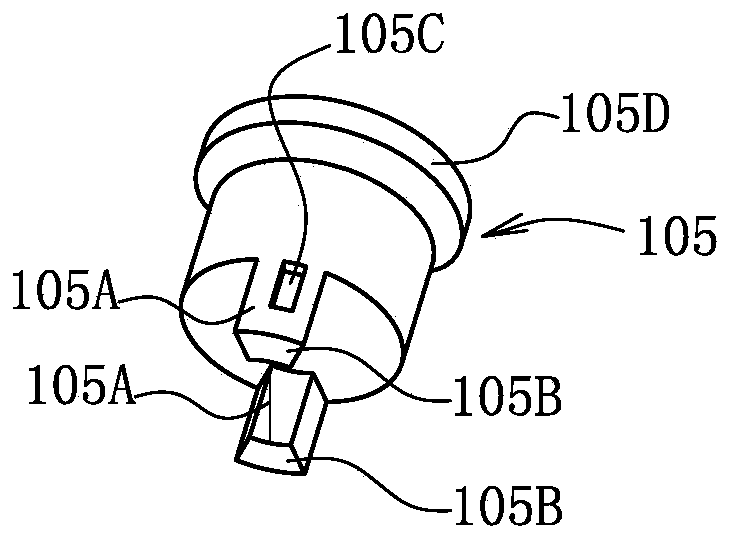

[0036] In the sliding sleeve 103, the space between the screw shaft 102 and the piston 105 is the sliding sleeve cavity Q, the return spring 104 is clamped between the screw shaft 102 and the piston 105, and the joint force of the return spring 104 and the oil pressure on the piston 105 Far less than the force of the valve spring on the piston 105. The sliding sleeve 103 is provided with an oil inlet hole 107 and a limit oil ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com