Wind preventing gas stove combustion device and method

The technology of a combustion device and a gas stove, which is applied in the direction of combustion methods, gas fuel burners, burners, etc., can solve the problems of poor air mixing effect and unfavorable gas combustion efficiency, etc., and achieve the effect of strong practicability and improved mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

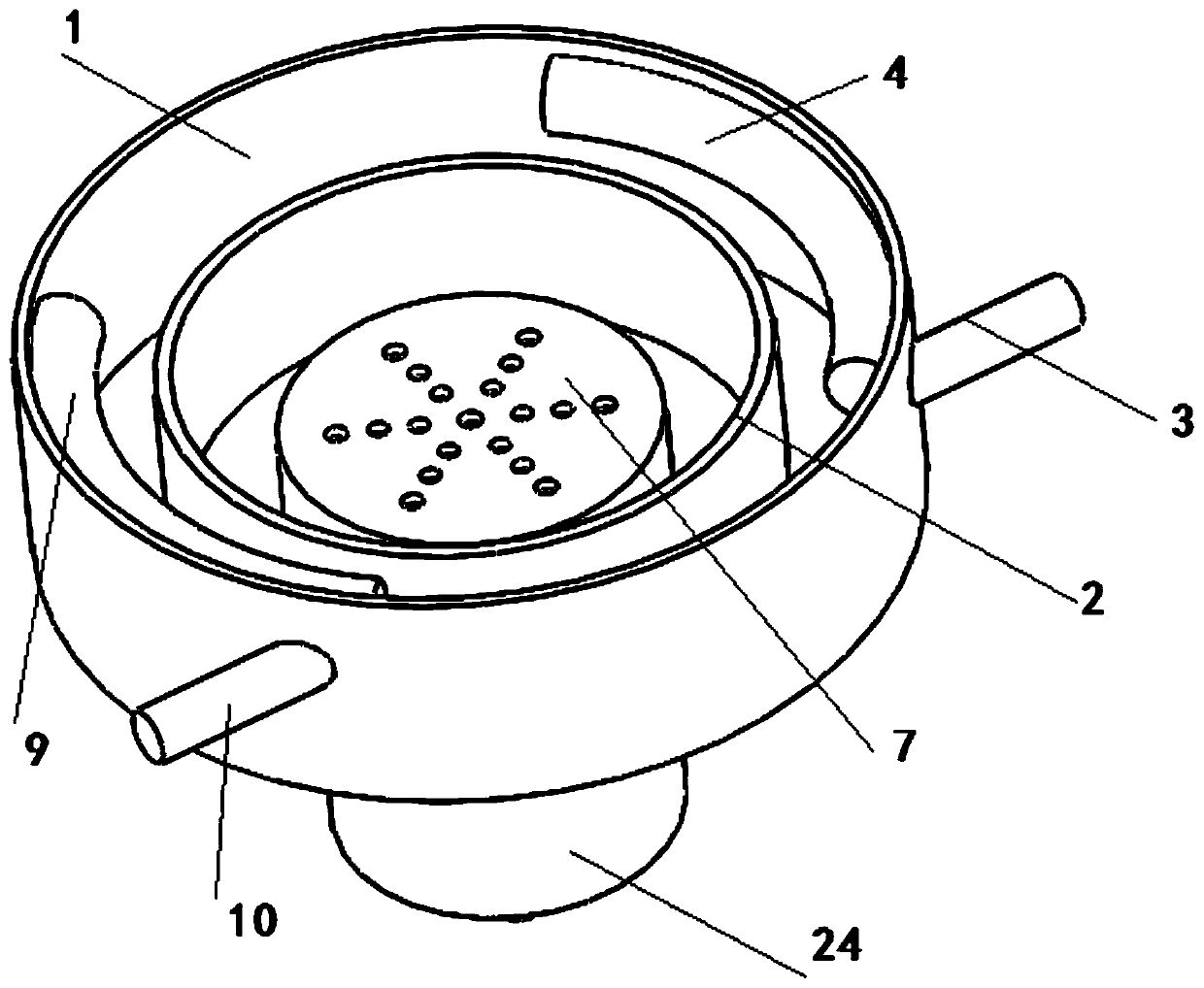

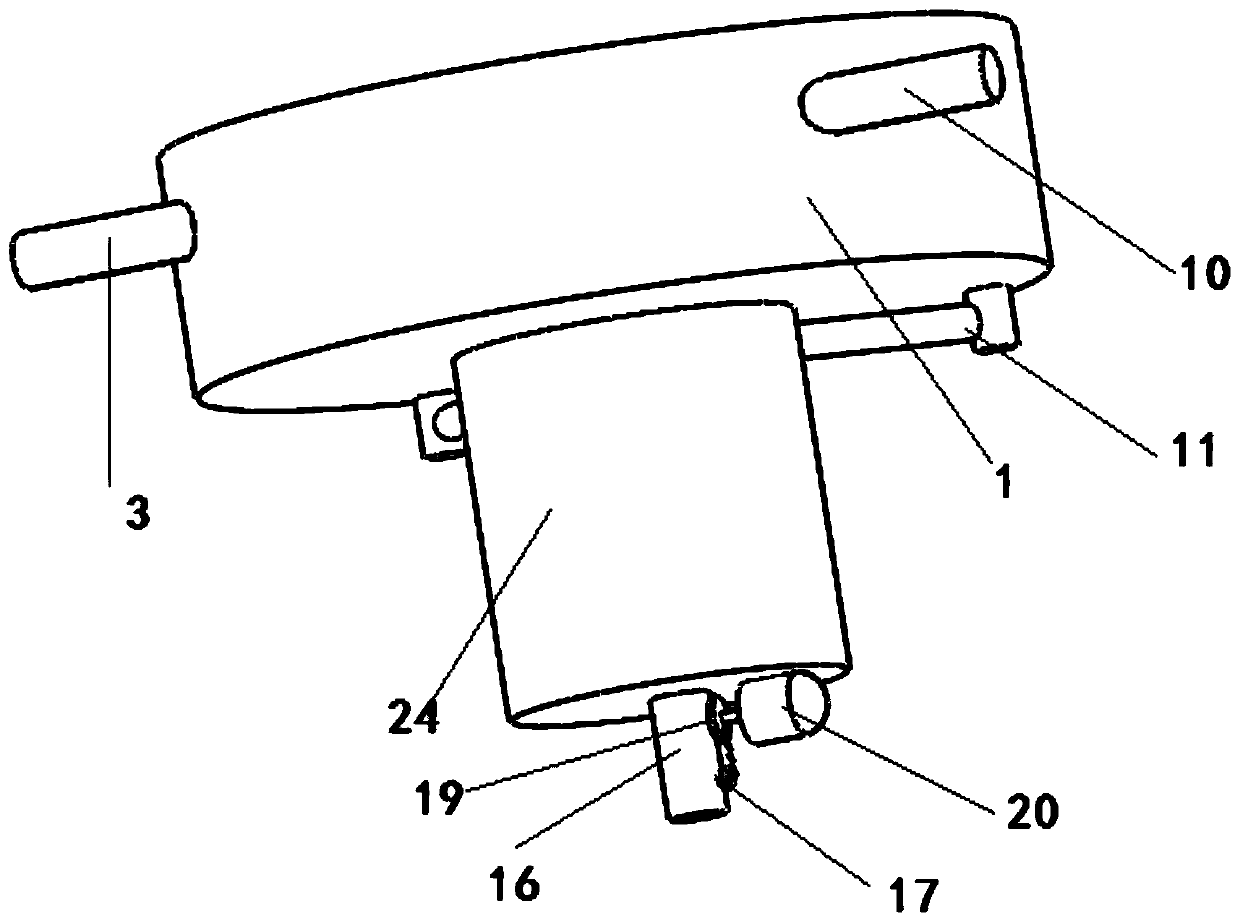

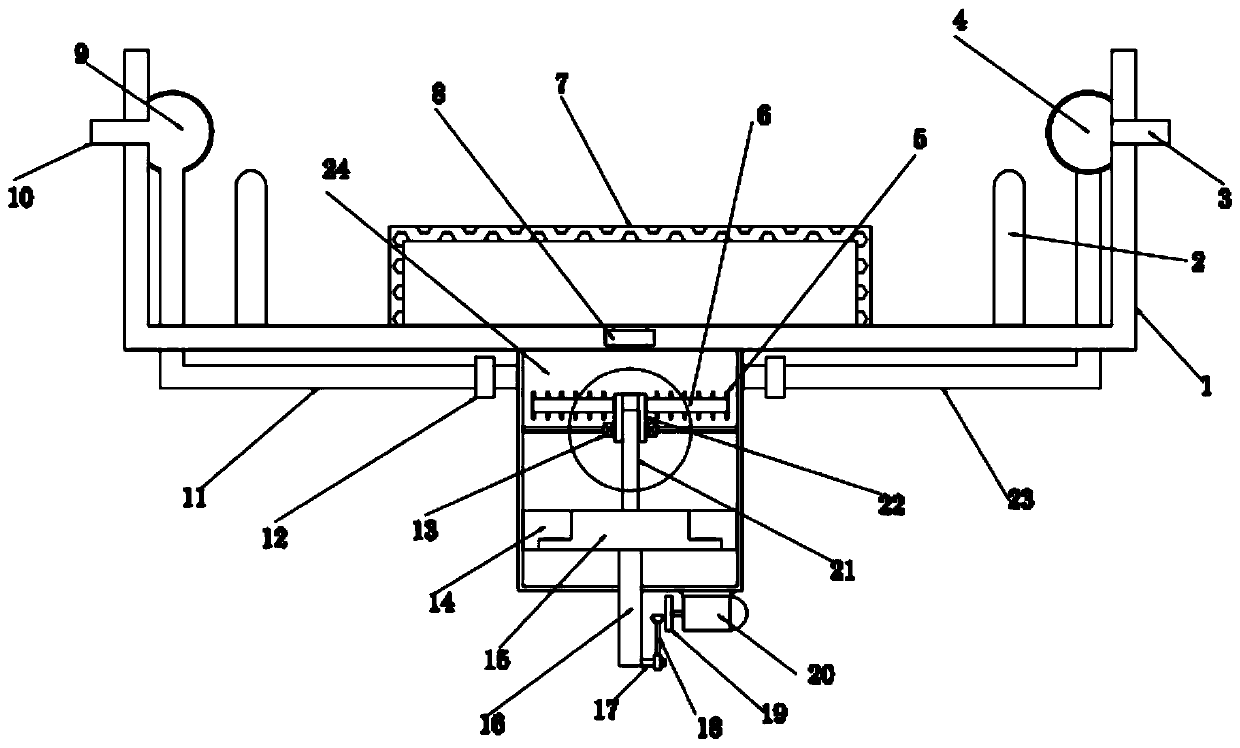

[0028] see Figure 1-4 , in an embodiment of the present invention, a windproof gas stove combustion device includes a support plate 1, and the support plate 1 is composed of a support plate and an annular windshield arranged on the outside of the support plate;

[0029] The middle position of the support plate 1 is provided with an air supply hole and a one-way valve and a pressure limiting valve 8 arranged at the air supply hole. A buffer cover 7 is arranged on the upper surface of the support plate where the air supply hole is located. Air jet holes, the upper end of the support plate 1 outside the buffer cover 7 is equipped with a support ring 2 for supporting the pot body;

[0030] The height of the support ring 2 is 1 / 2 of the height of the annular windshield, so that the influence of the external air flow on the flame can be avoided, so that the device has wind resistance;

[0031] The lower end of the gas injection hole is connected to the mixing box 24 arranged on th...

Embodiment 2

[0045] The difference from Example 1 is that: the first heat exchange tube 4 and the second heat exchange tube 9 are made of metal material with good thermal conductivity, and the inner walls of the two heat exchange tubes are provided with heat exchangers to increase the heat exchange area. hot fins.

[0046] The working principle of the present invention is: Step 1: Drive the piston block 15 to move downward by pushing the assembly, so that the mixing box 24 is in a negative pressure state, so that air and gas will be sucked into the mixing box 24, thereby realizing preliminary mixing Step 1: When the piston block 15 moves downward, the driving screw 21 cooperates with the nut ring 22, thereby driving the nut ring 22 to rotate, and the nut ring 22 drives the stirring plate 6 and the stirring rod 5 to perform secondary mixing treatment on the materials;

[0047] Step 2: When the piston block 15 moves upward, the piston block 15 will compress the initially mixed gas to mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com