Rail type electromagnetic gun material performance testing platform

A technology of material performance and test platform, applied in the direction of analyzing materials, weapon testing, optical testing flaws/defects, etc., can solve the problem of difficulty in providing orbital service performance test results, restricting the performance improvement and breakthrough of orbital electromagnetic guns, and inability to conduct orbital performance tests, etc. problems, to improve the service life and energy utilization, reduce ablation, and facilitate installation and removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] As an implementation, the test of the railgun includes the following steps:

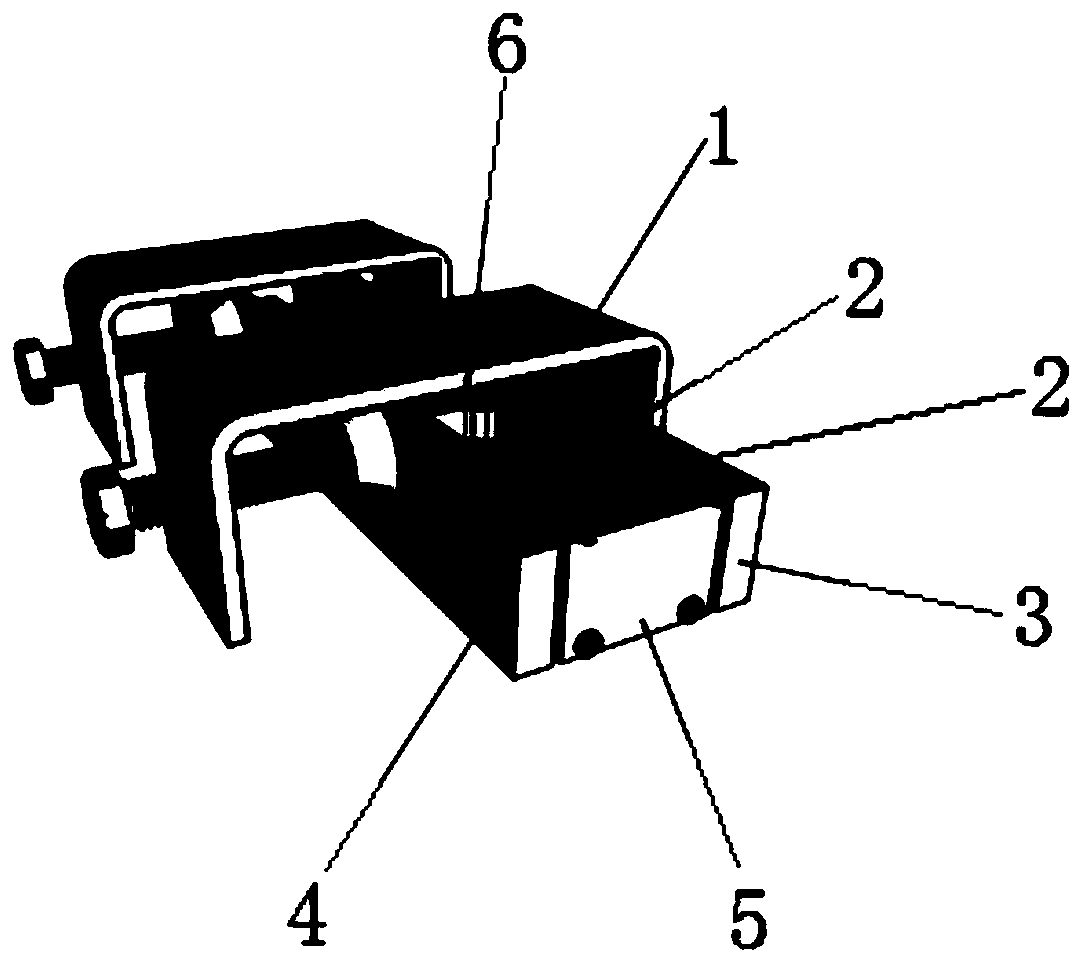

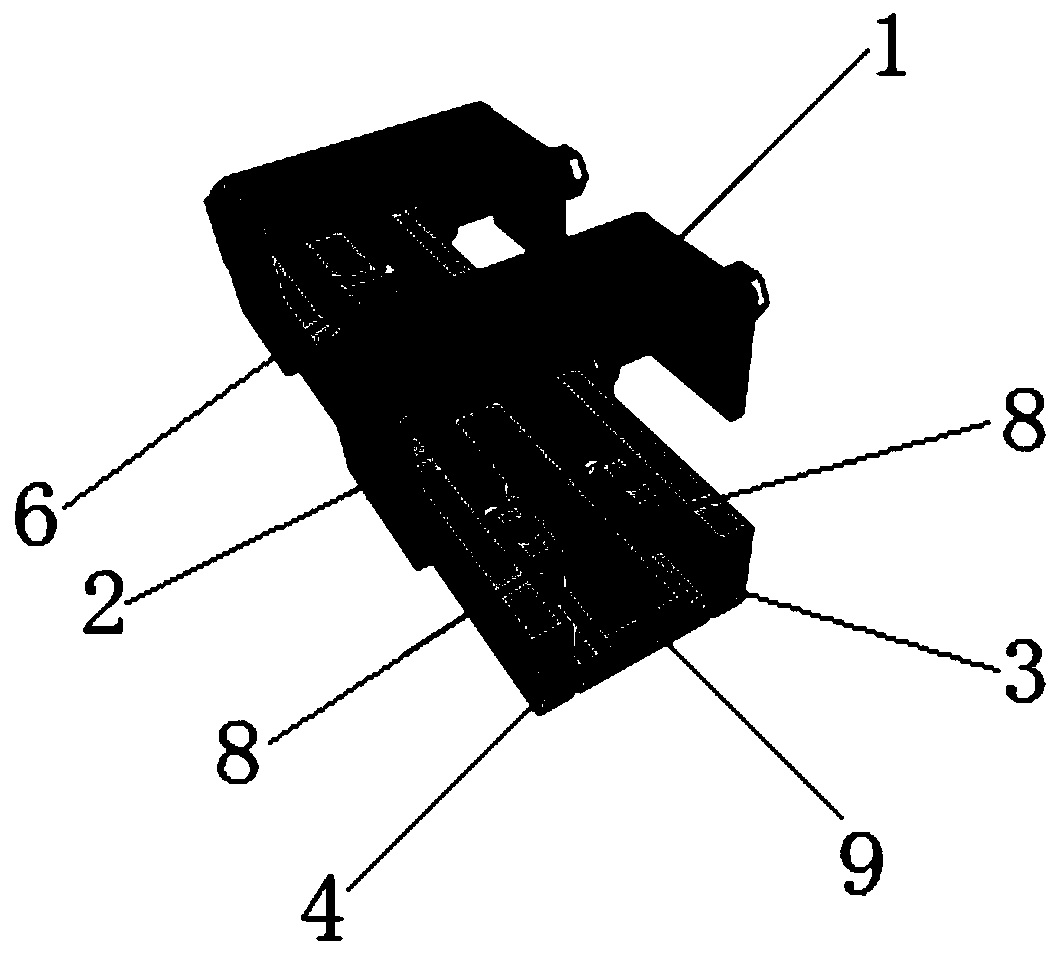

[0063] Step 1, fix the guide rail in the guide rail groove of the fixing device, ensure that the two ends of the guide rail are in good contact with the corresponding conductive connectors at both ends of the fixing device, and put the armature 6 in the middle of the two parallel guide rails so that the bottom surface of the armature 6 is in contact with the base 9 Surface contact is realized, and both sides of the armature 6 are in surface contact with the guide rail;

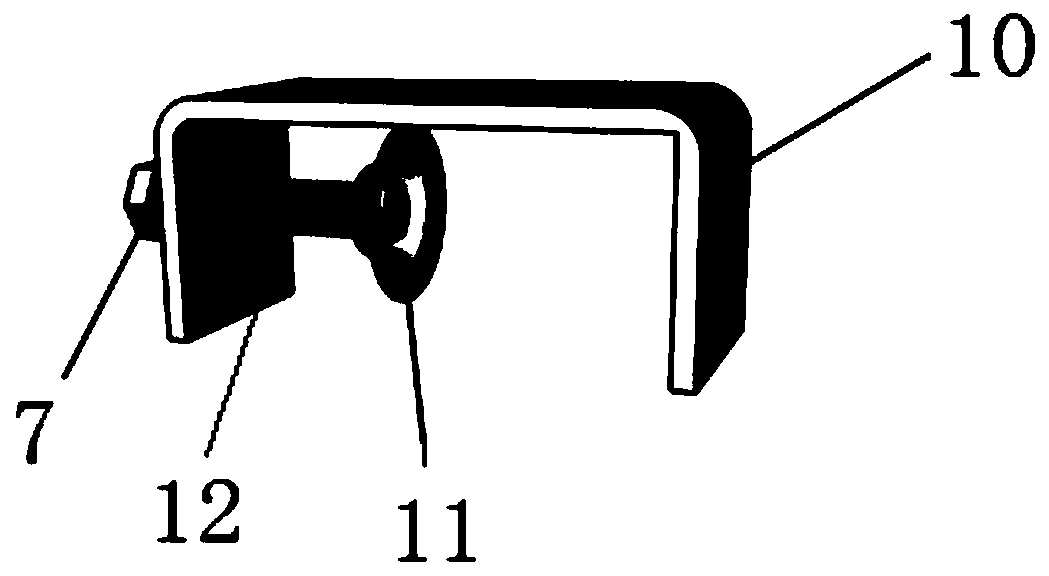

[0064] Step 2, tighten the bolt 12 of the U-shaped clamping device 1 to ensure that the armature 6 of the guide rail is well connected, and adjust the resistance of the resistance box to determine the resistance of the external circuit;

[0065] Step 3, turn on the voltmeter at both ends of the capacitor, press the charging button, the voltage indication is the charging voltage of the capacitor;

[0066] Step 4, after the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap