Manufacturing process of pre-crosslinked photovoltaic module and photovoltaic module

A manufacturing process and photovoltaic module technology, applied in sustainable manufacturing/processing, photovoltaic power generation, final product manufacturing, etc., can solve problems such as color EVA overflow, achieve the effects of reducing fluidity, improving dimensional stability, and ensuring output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

[0020] like figure 1 and figure 2 As shown, the present invention discloses a manufacturing process of pre-crosslinked photovoltaic modules, comprising the following steps:

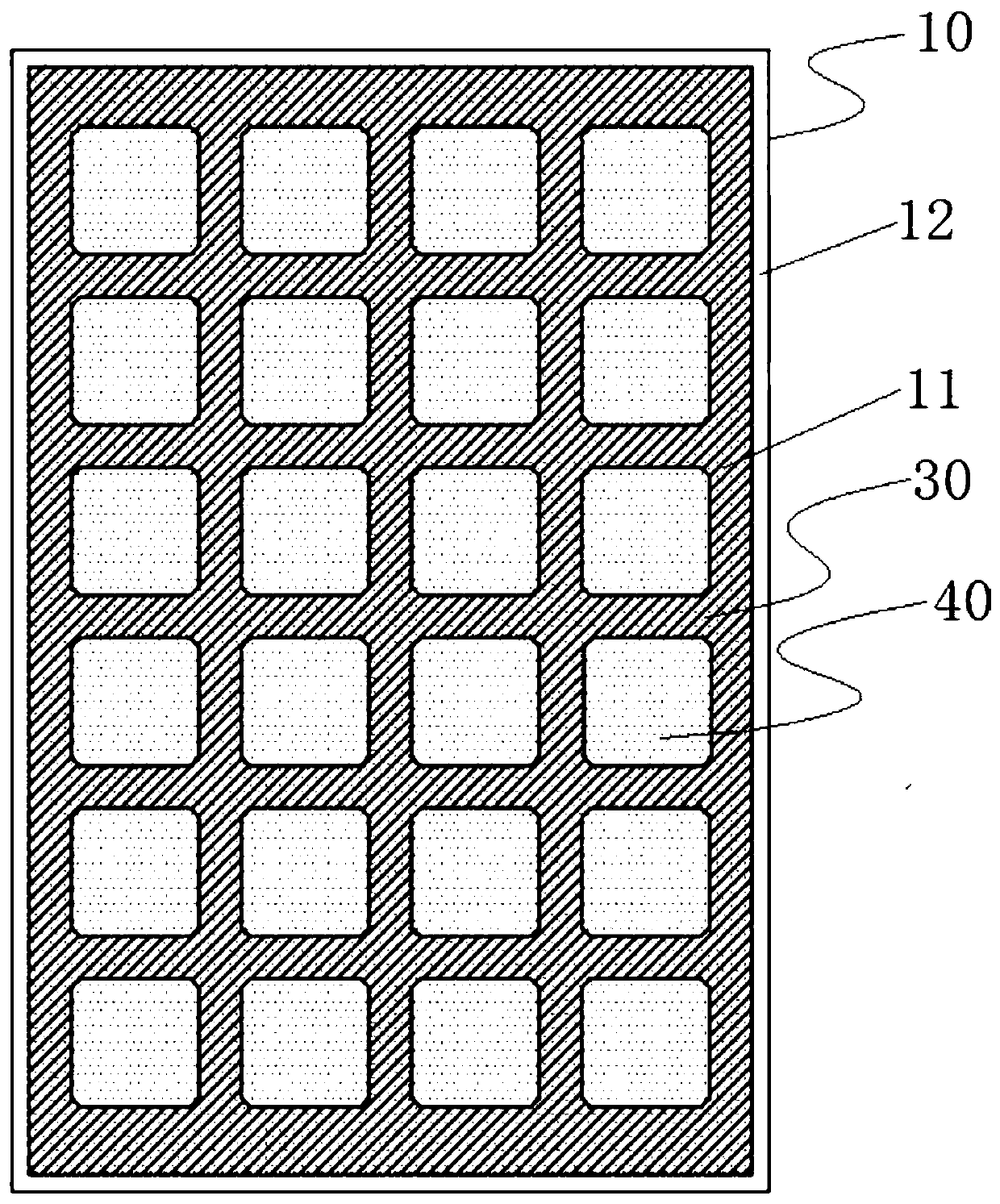

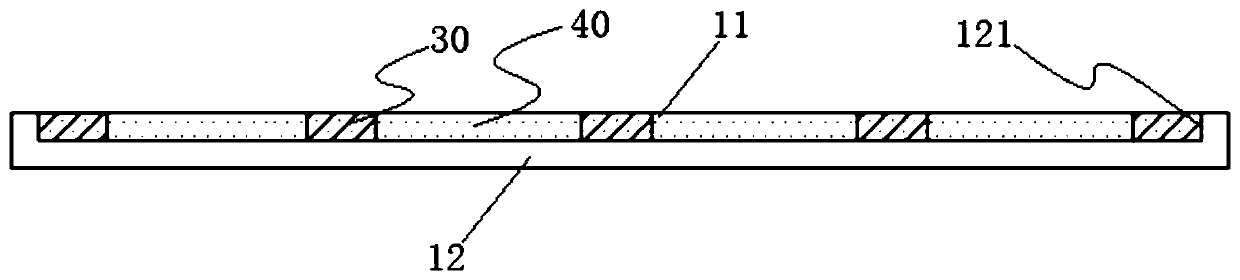

[0021] S10: Composite the colored EVA film 11 and the transparent EVA film 12 to form a composite packaging adhesive film layer 10;

[0022] S20: According to the distribution position of the cells, correspondingly divide the non-cell coverage area 30 and the cell coverage area 40 on the composite encapsulation film layer 10;

[0023] S30: Perform pre-crosslinking on the non-cell covered area 30 on the composite encapsulation film layer 10 .

[0024] In the manufacturing process of the pre-crosslinked photovoltaic module of the present invention, by performing pre-crosslinking on the non-cell covering area 30 in the composite encapsulation adhesive film l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com