Power distribution cabinet automatic dust removal mechanism with dead corner cleaning function

A technology for power distribution cabinets and transmission mechanisms, which is applied in the direction of removing smoke and dust, substation/distribution device casings, and electrical components. , The moving process is smooth and smooth, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

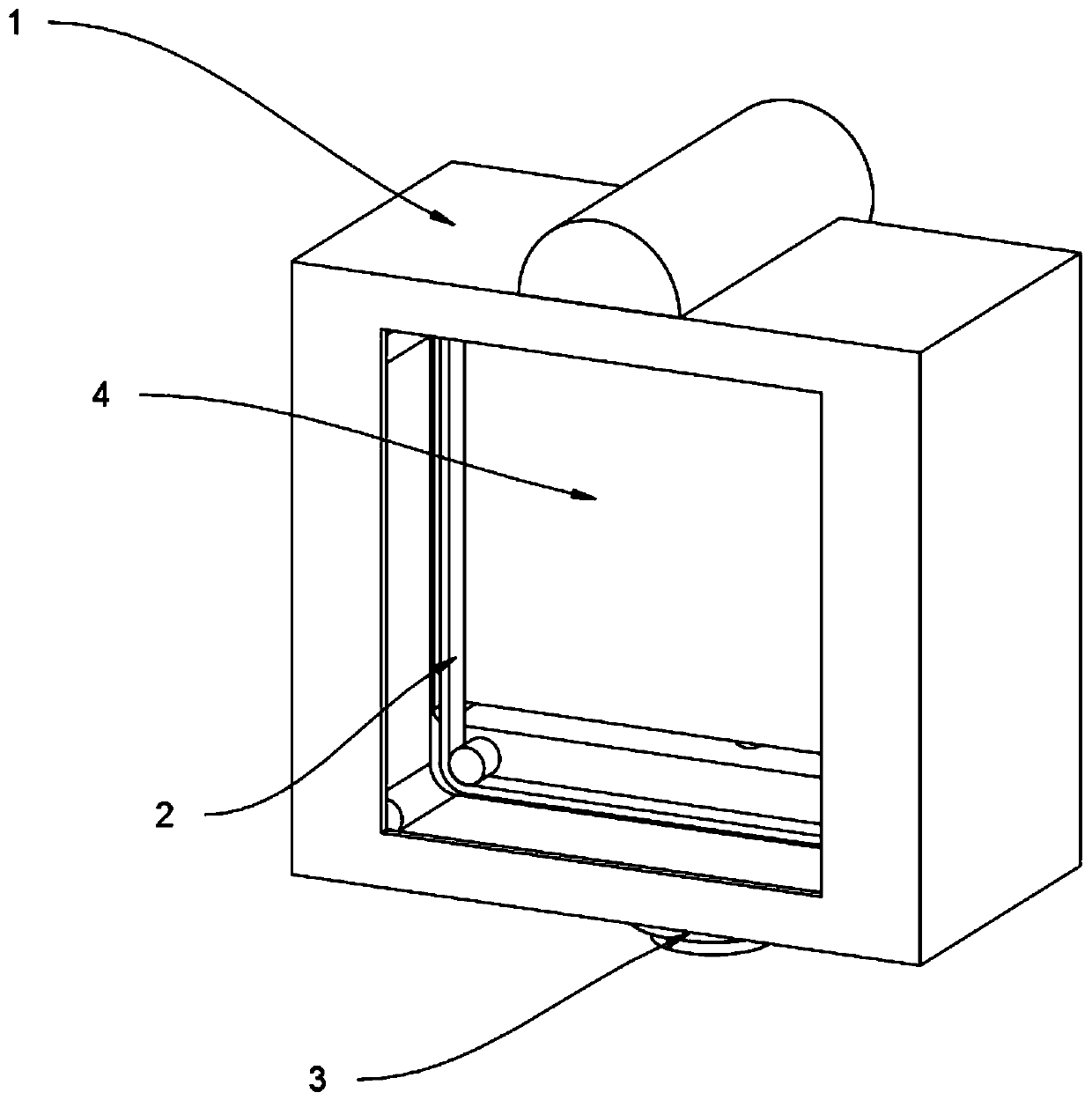

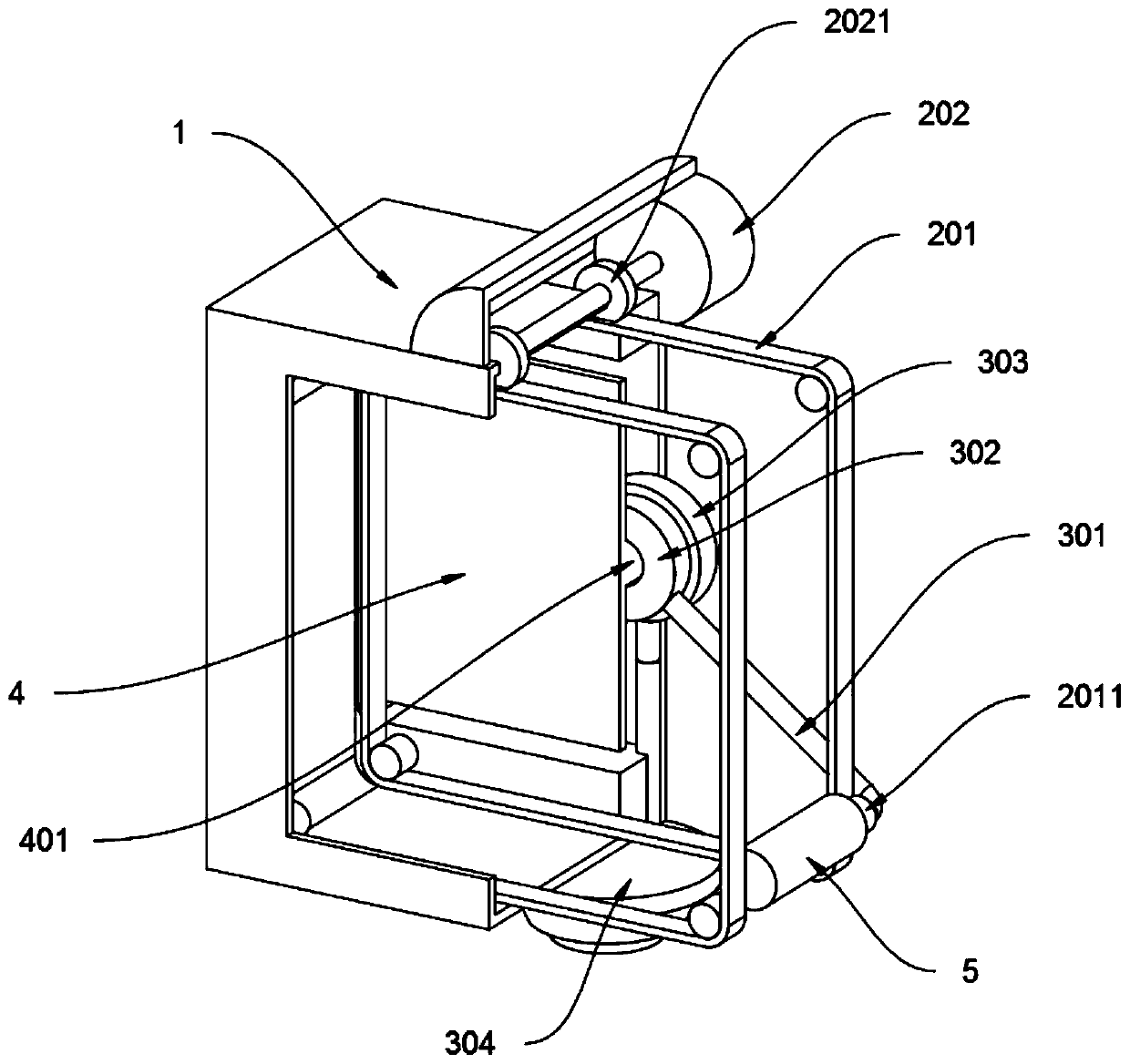

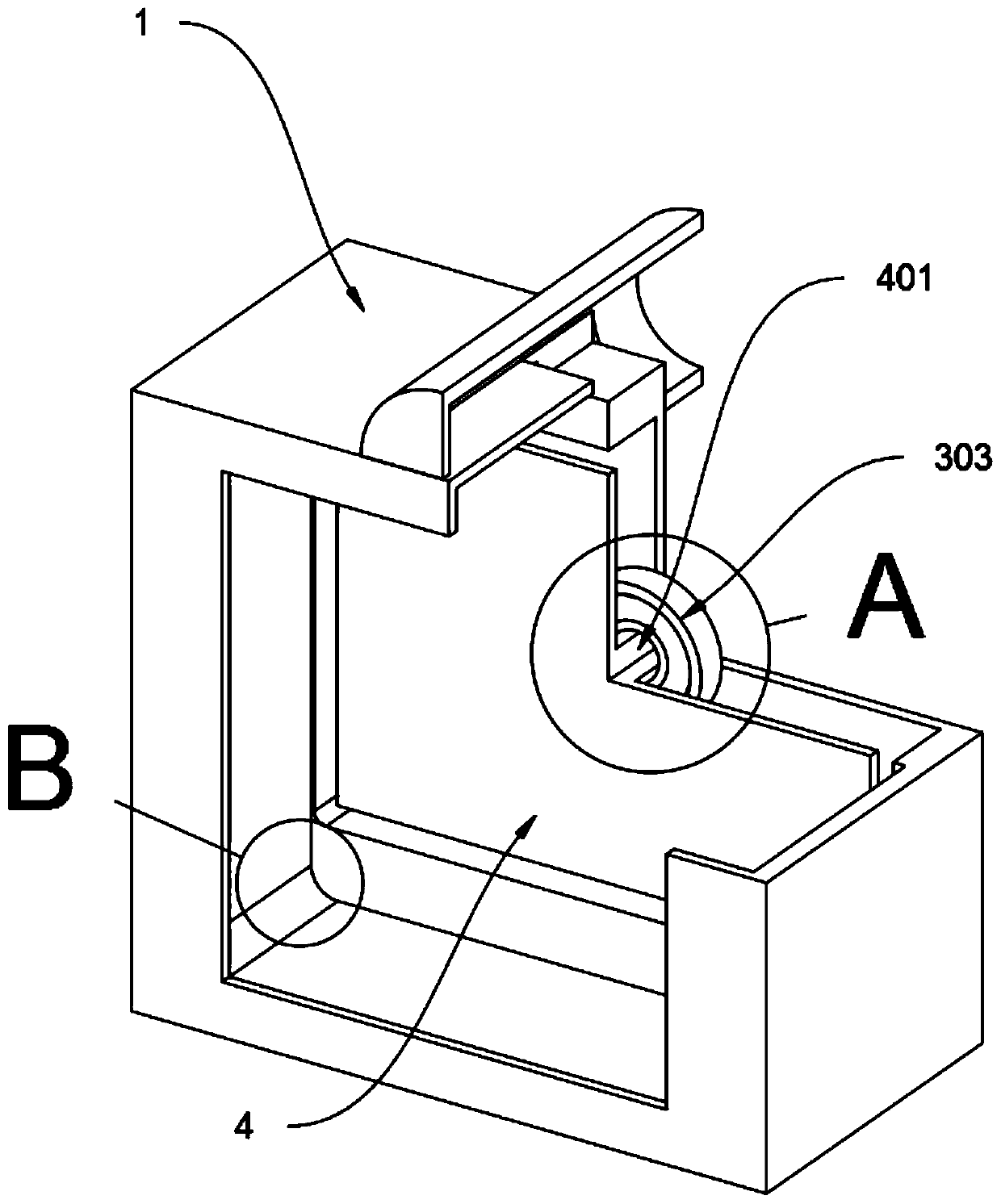

[0037] as attached figure 1 to attach Figure 9 Shown:

[0038] The present invention provides an automatic dust removal mechanism for a power distribution cabinet with the function of cleaning dead corners, which includes a housing 1, a dust removal mechanism 3 and an electrical installation plate 4; a transmission mechanism 2 is provided inside the housing 1; an arc is provided at an inner corner of the housing 1 Shaped chamfering, and the bottom of the opening of the dead corner dust removal block 6 is provided with arc-shaped chamfering, as attached figure 2 , attached image 3 And attached Figure 9As shown, the moving process of the dead corner dust removal block 6 on the inner wall of the casing 1 is smoother and smoother, and the phenomenon that the dead corner dust removal block 6 is stuck will not cause the device to fail, and the design of the internal chamfer of the casing 1 is also convenient. By manually cleaning the inside of the power distribution cabinet,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com