Surface acoustic wave regulated high-flux micro-droplet generation device and surface acoustic wave regulated high-flux micro-droplet generation method

A surface acoustic wave and generation device technology, applied in the field of microfluidics, can solve the problems of limited generation rate, unsuitable for the generation of large-flux micro-droplets, and the generation rate is difficult to meet the needs, so as to achieve firm bonding, overcome excessive dependence, more observable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing.

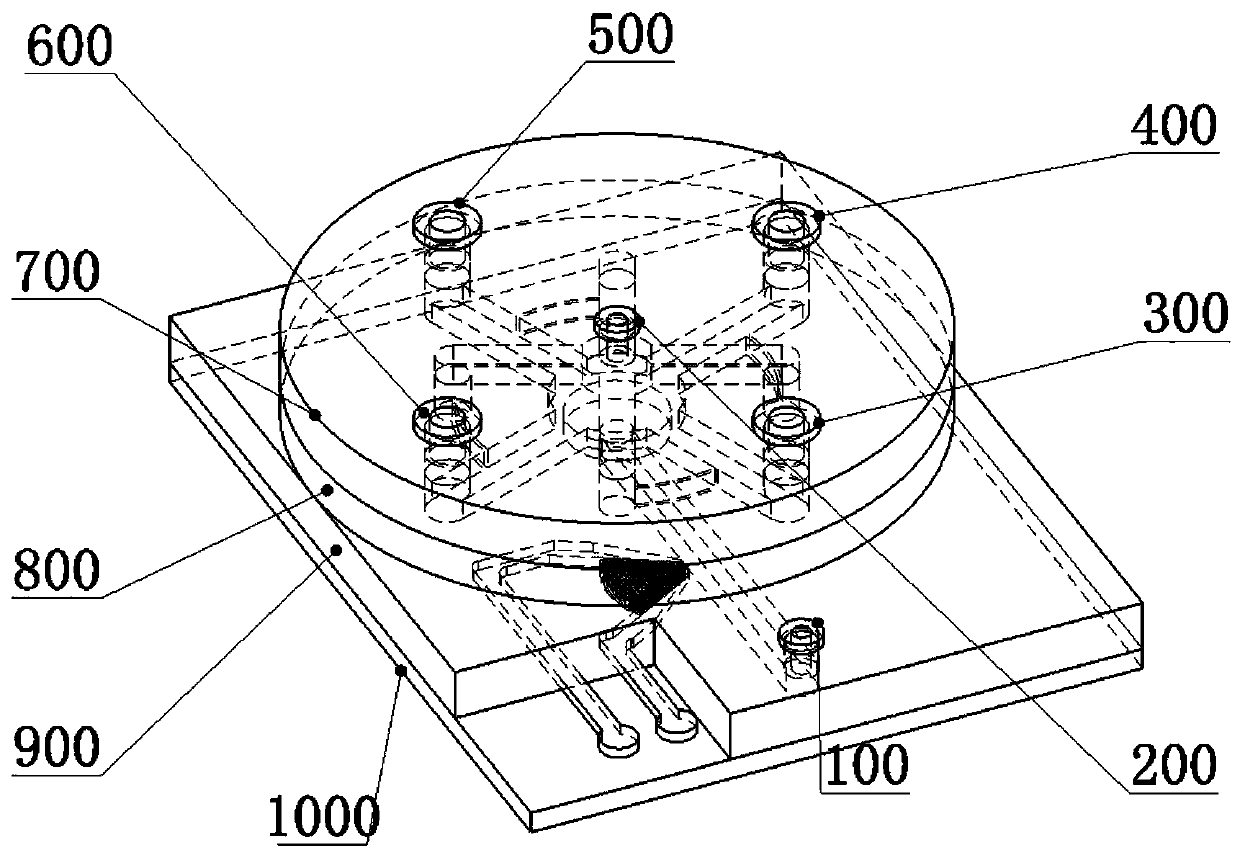

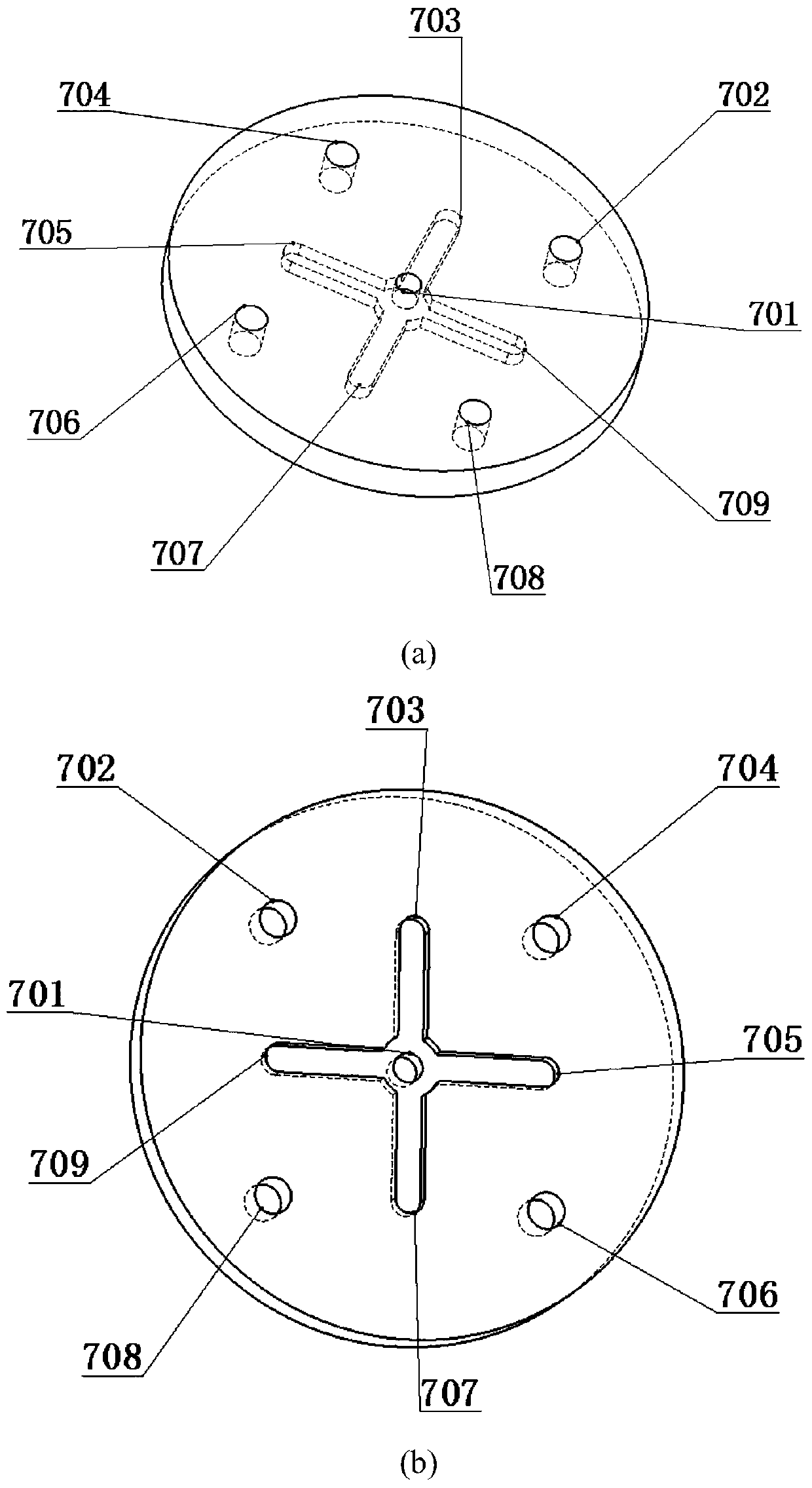

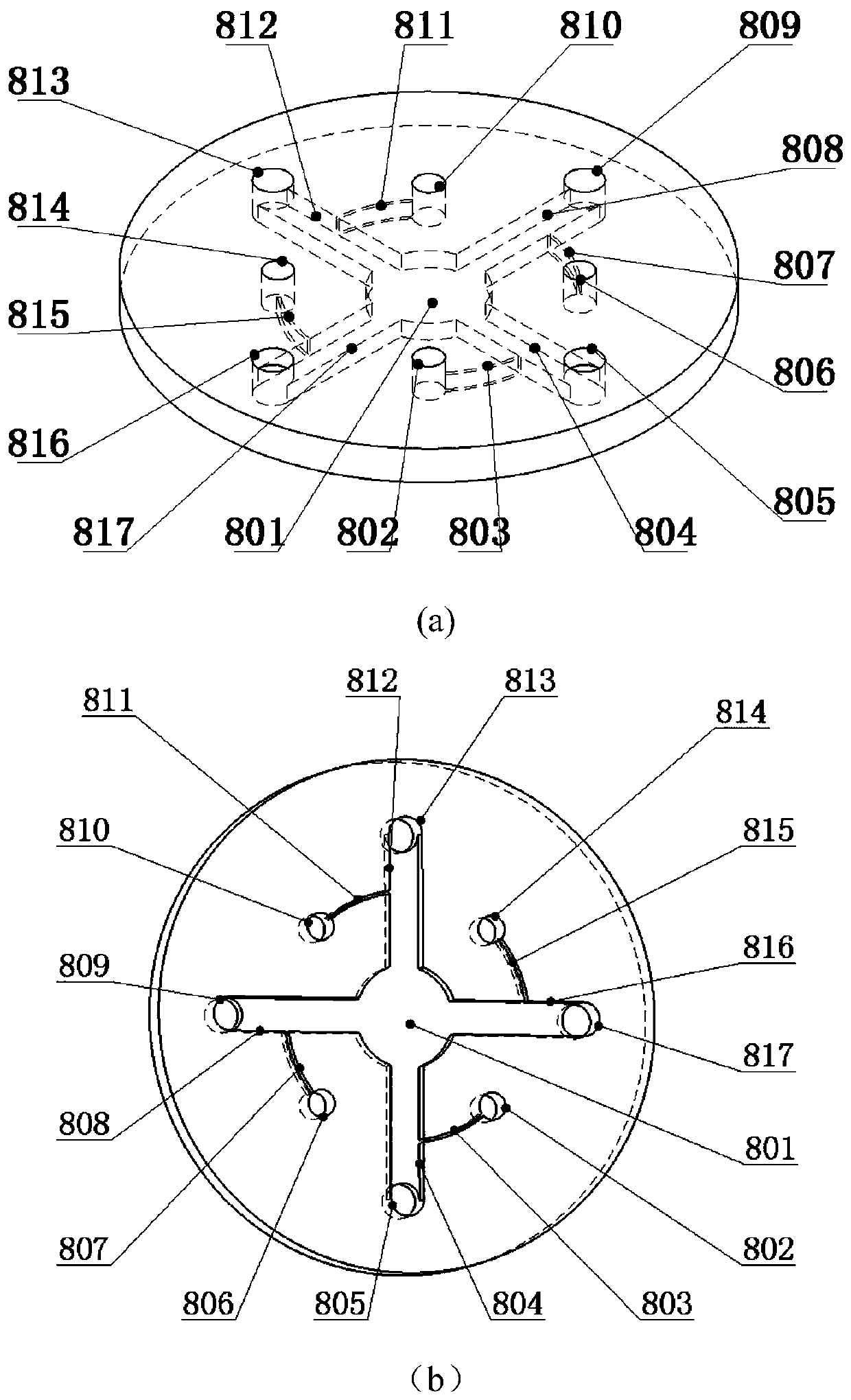

[0035] refer to figure 1 , a high-throughput micro-droplet generation device regulated by surface acoustic waves, including an interdigital transducer 1000, an arc-shaped electrode is fabricated on the interdigital transducer 1000, and PDMS is bonded to the top of the interdigital transducer 1000 Micro-channel system, the arc-shaped electrode cooperates with the PDMS micro-channel system; the PDMS micro-channel system is formed by bonding the top layer PDMS channel 700, the middle layer PDMS channel 800 and the bottom layer PDMS channel 900; the PDMS micro channel system has The continuous phase inlet joint 100, the dispersed phase inlet joint 200, the first collection outlet joint 300, the second collection outlet joint 400, the third collection outlet joint 500, and the fourth collection outlet joint 600; the PDMS microfluidic channel system is used to accommodate the disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com