Efficient transformer testing system

A test system and transformer technology, applied in sorting and other directions, can solve the problems of low equipment utilization, low work efficiency, single function, etc., and achieve the effects of high work efficiency, improved work efficiency, and high detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

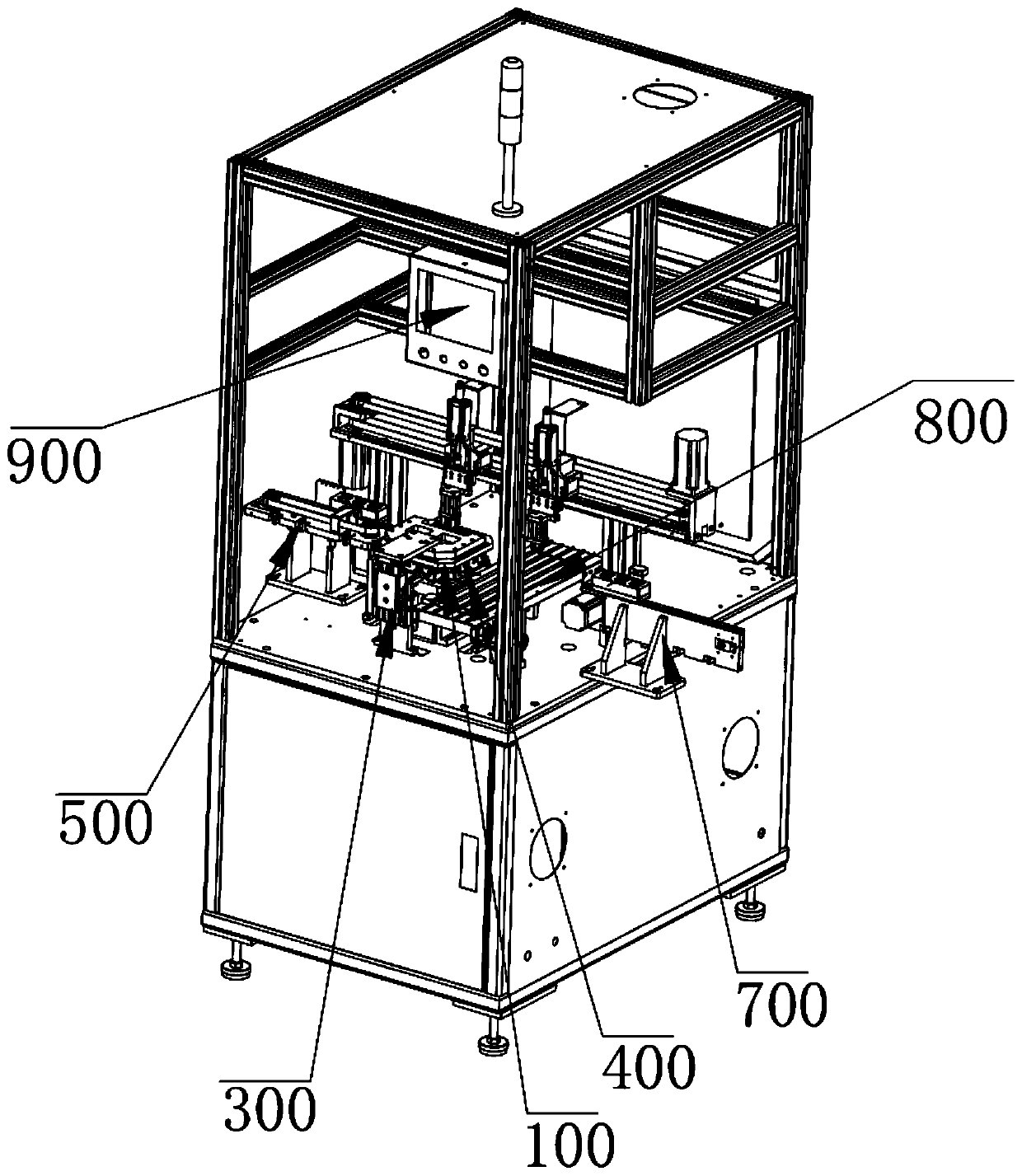

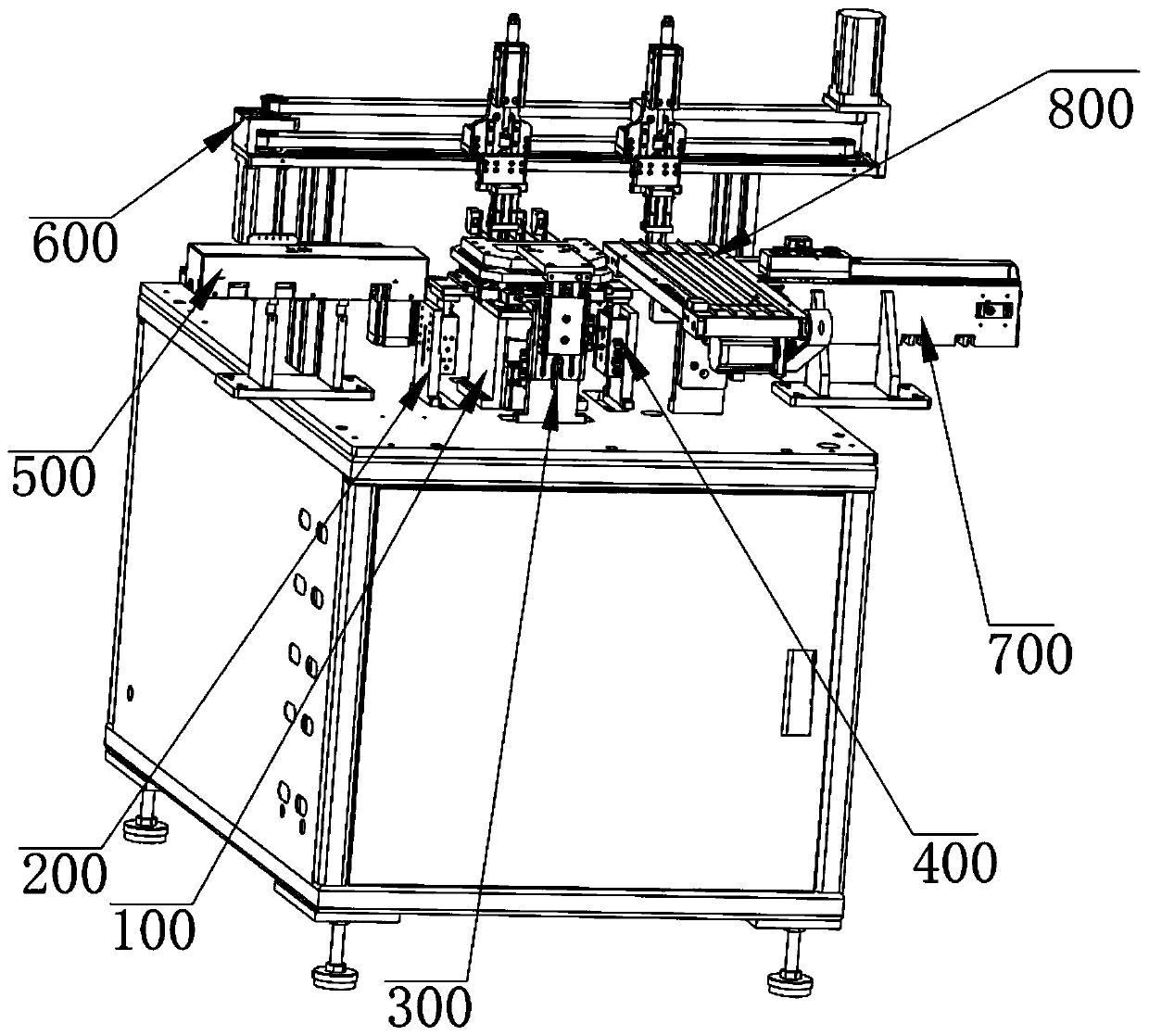

[0042] Such as Figure 1 ~ Figure 2 As shown, they are structural schematic diagrams of different viewing angles of the present invention.

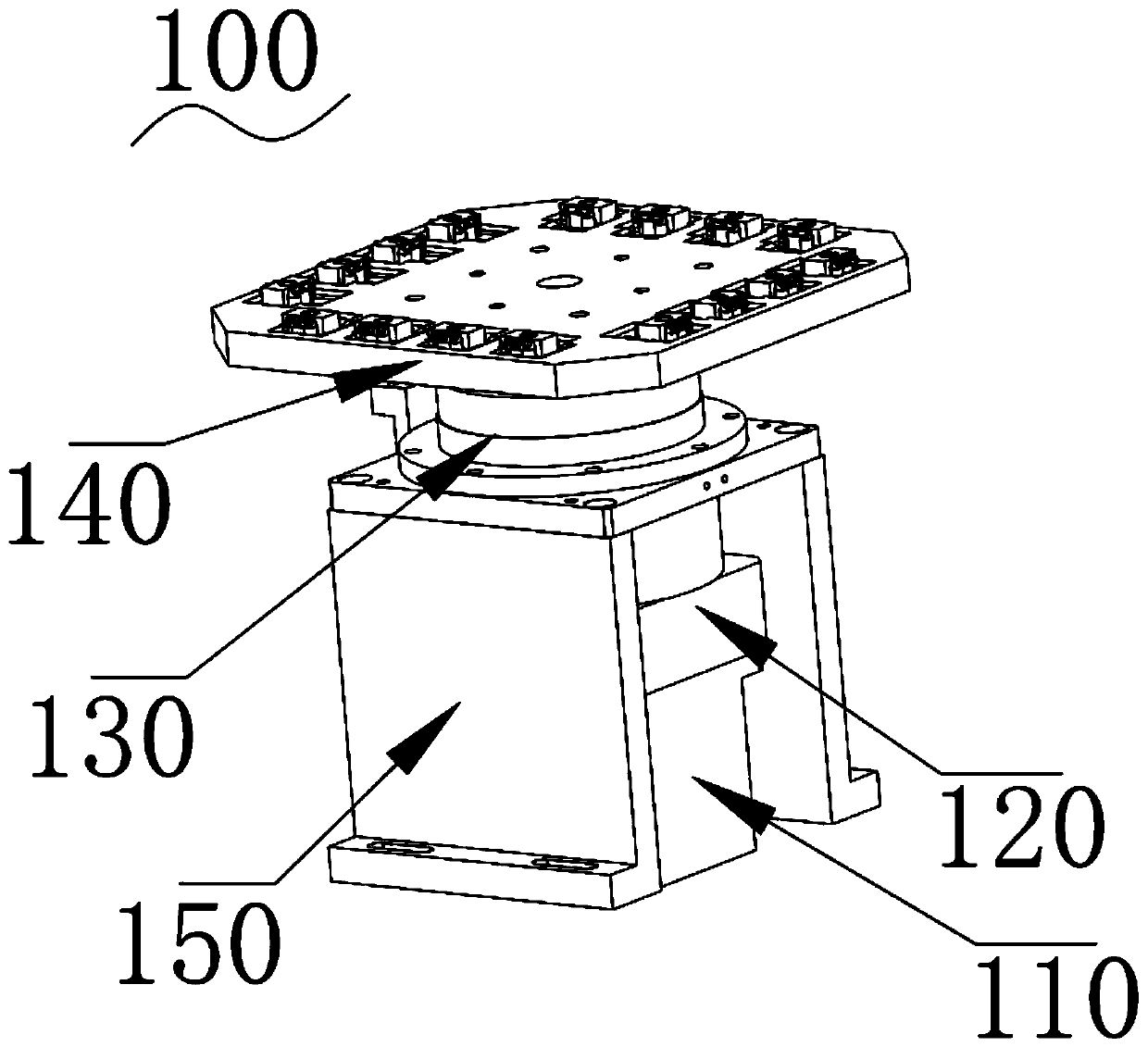

[0043] The high-efficiency transformer testing system is characterized in that it includes a workbench, a first test station 200, a second test station 300, and a third test station 400, which are located on the workbench and sequentially perform triple performance tests on transformers. The test station 200 is arranged opposite to the third test station 400, and the third test station 400 is arranged on one side of the connecting line between the first test station 200 and the third test station 400, and is perpendicular to the first test station at the same time. 200 and the third test station 400, also including the transfer mechanism 100 for transferring the transformer in the space enclosed by the first test station 200, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com