Plasterboard pouring device

A paper-faced gypsum board and machine technology, which is applied in the direction of surface layering devices, auxiliary molding equipment, ceramic molding machines, etc., can solve the problem that the cutting speed cannot match the speed of paper movement, which affects the quality of gypsum board processing, The thickness of the gypsum layer fluctuates out of tolerance, etc., to achieve the effect of reducing the amount of gypsum slurry, saving materials, and evenly distributing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the drawings and embodiments.

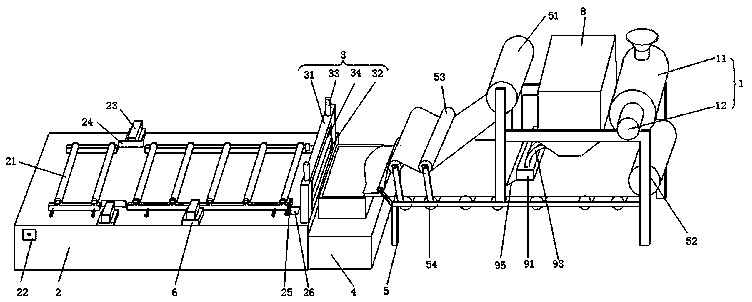

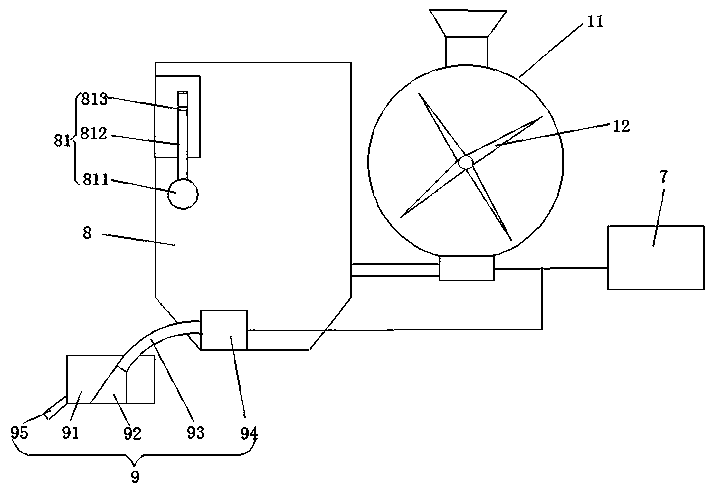

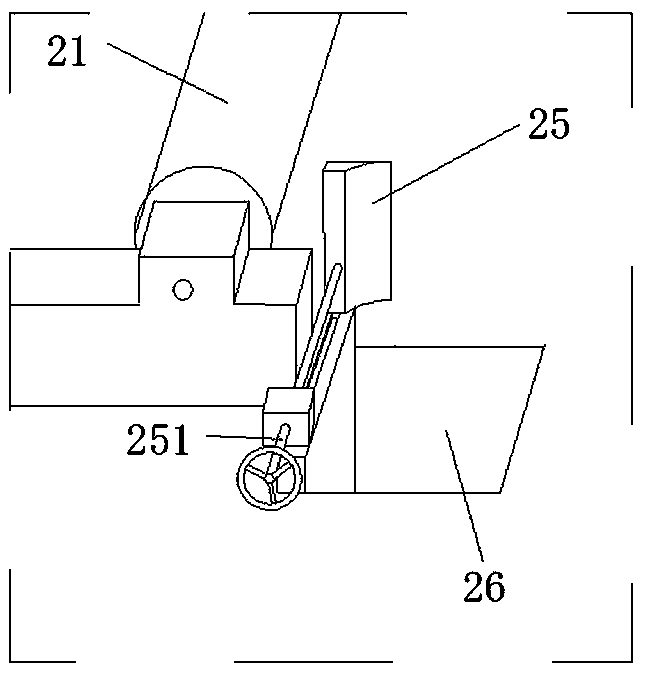

[0030] Please refer to figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 ,among them figure 1 It is a schematic structural diagram of a preferred embodiment of the gypsum board pouring device provided by the present invention; figure 2 for figure 1 The structure diagram of the mixing mechanism, storage tank and slurrying mechanism shown; image 3 for figure 1 The structure diagram of the scraper shown; Figure 4 for figure 1 The structure diagram of the forming mechanism shown; Figure 5 It is a schematic diagram of the control relationship of the gypsum board pouring device provided by the present invention.

[0031] Refer to figure 1 As shown, a gypsum board pouring device includes a machine table 2, in which,

[0032] The top of the machine platform 2 is rotatably connected to a row of rollers 21, the rollers 21 are arranged along the width direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com