Large-scale biomass fixed-bed gasification system and the measurement method of cold and hot gasification efficiency

A gasification system and biomass technology, which is applied in the field of large-scale fixed-bed gasification system of biomass and the measurement of cold and hot gasification efficiency, can solve the difficulty of accurate gasification efficiency of cold gas and hot gas of large-scale fixed-bed gasifier Calculation and other issues to achieve the effect of improving accuracy and improving the accuracy of determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

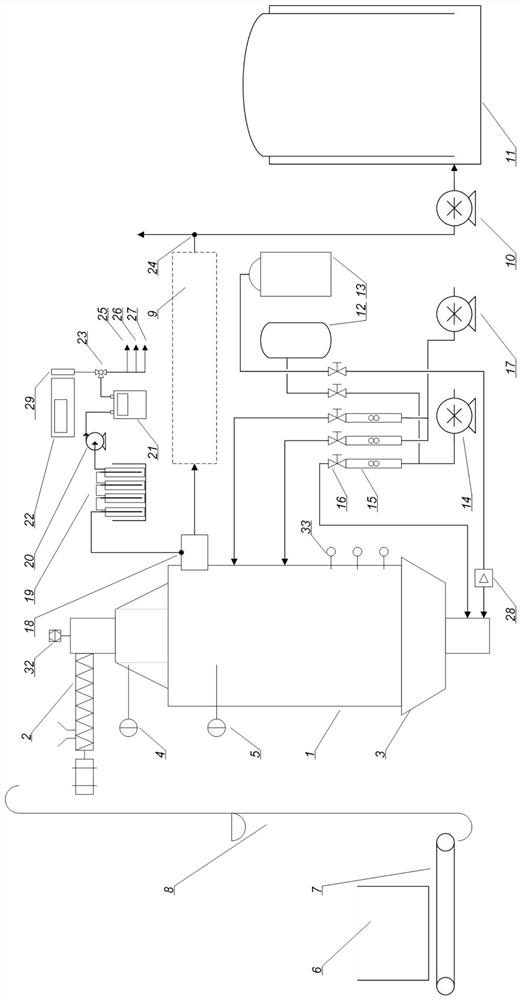

[0036] according to figure 1 As shown, this embodiment proposes a large-scale biomass fixed-bed gasification system, including a furnace body 1, a gas sampling point 18 installed on the furnace body 1, and a fire grate 3 installed at the lower end of the furnace body. A distance meter 32 is installed on the top, an absorption device 19 is installed at the gas outlet end of the gas sampling point 18, a vacuum pump 20 is installed at the gas outlet end of the absorption device 19, a gas meter 21 is installed at the gas outlet end of the vacuum pump 20, and a gas meter 21 is installed at the gas outlet end of the gas meter 21 and a switching valve 23 One way of the switch valve 23 is connected with the oxygen electrode 29 of the oxygen analyzer 22, and the other way of the gas outlet is also connected with the gas bag 25, the gas chromatograph 26 and the online gas analyzer 27, and the main pipeline of the gas outlet where the gas sampling point 18 is located is connected with the...

Embodiment 2

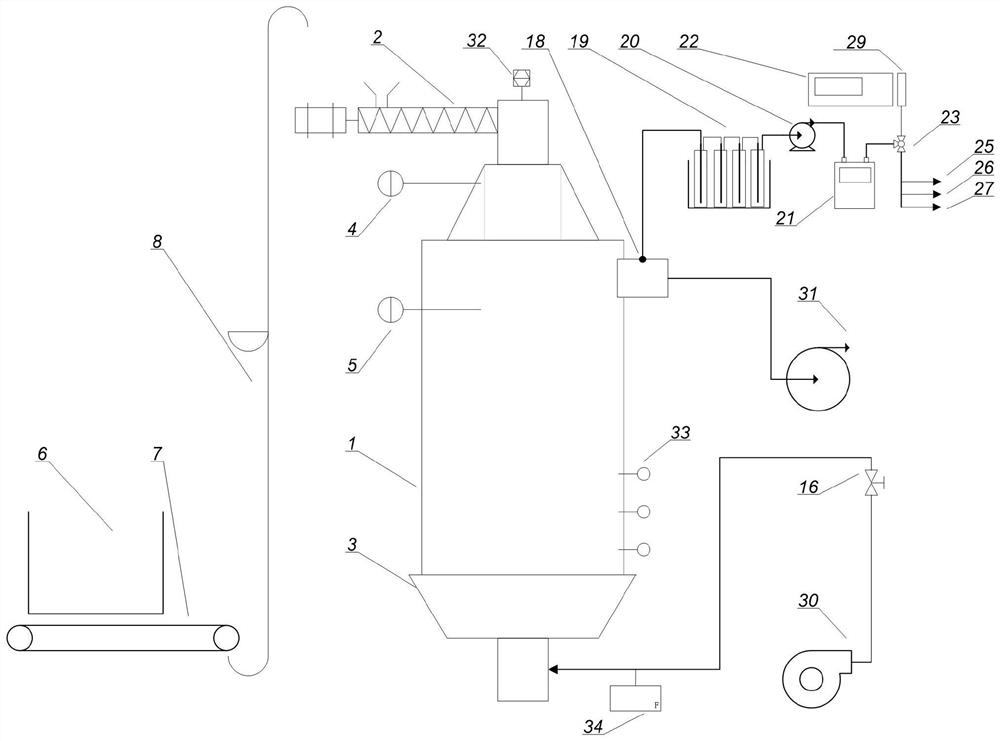

[0050] according to figure 2 As shown, this embodiment proposes a large-scale biomass fixed-bed gasification system, including a furnace body 1, a gas sampling point 18 installed on the furnace body 1, and a fire grate 3 installed at the lower end of the furnace body. A rangefinder 32 is installed on the top, an absorption device 19 is installed at the gas outlet of the gas sampling point 18, a vacuum pump 20 is installed at the gas outlet of the absorption device 19, a gas meter 21 is installed at the gas outlet of the vacuum pump 20, and a gas meter 21 is installed at the gas outlet of the gas meter 21 and a switching valve 23 One way of the switching valve 23 is connected with the oxygen electrode 29 of the oxygen analyzer 22, and the other gas outlet is also connected with the gas bag 25, the gas chromatograph 26 and the online gas analyzer 27, and the gas outlet of the gas sampling point 18 is connected with the induced draft fan 31 Connection, the bottom of the furnace ...

Embodiment 3

[0061] On the basis of the large-scale biomass fixed-bed gasification system proposed in the first and second embodiments, more preferably, the absorption device 19 is composed of at least 6 sampling bottles connected in series and placed in the ice-water mixture, each Each sampling bottle is filled with 150mL of absorbing liquid. The collected gas samples have a relatively high temperature. After passing through the absorbing device 19, the temperature of the absorbing liquid is easily raised rapidly to make the absorbing liquid volatilize. Therefore, the absorbing liquid must be placed in a low-temperature environment. Under low temperature conditions, the low temperature property is maintained, and multiple sampling bottles in series ensure that the fly ash and tar in the gas sample are fully extracted.

[0062] The feed port of the furnace body 1 is equipped with a feed mechanism, which includes a feed bin 6, a horizontal conveyor 7, a vertical elevator 8 and a screw feeder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com