Water storage type water heater

A water heater and water storage technology, which is applied in the field of electrical appliances, can solve problems such as overheating of the water heater liner, achieve the effects of improving safety, improving structural sealing and strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

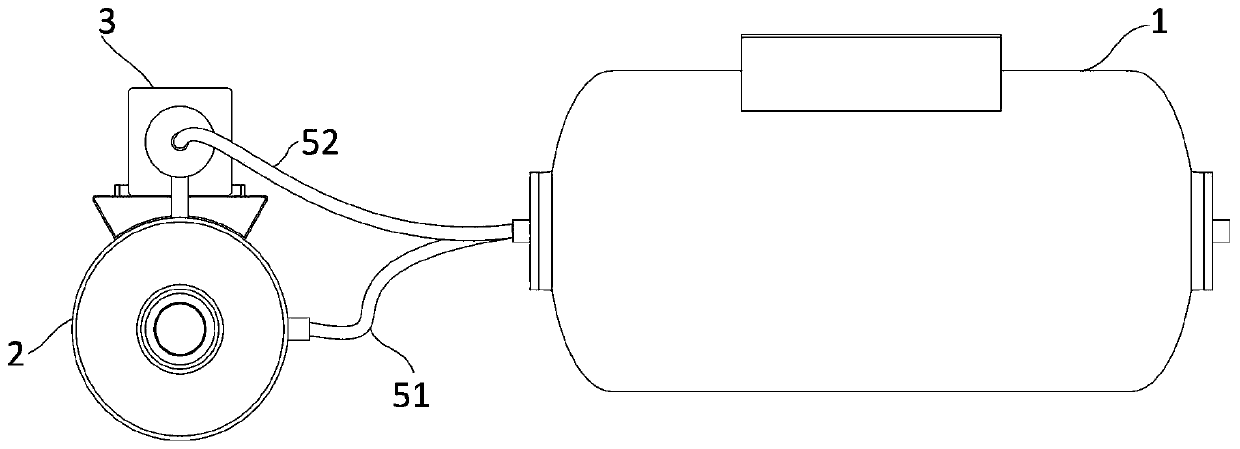

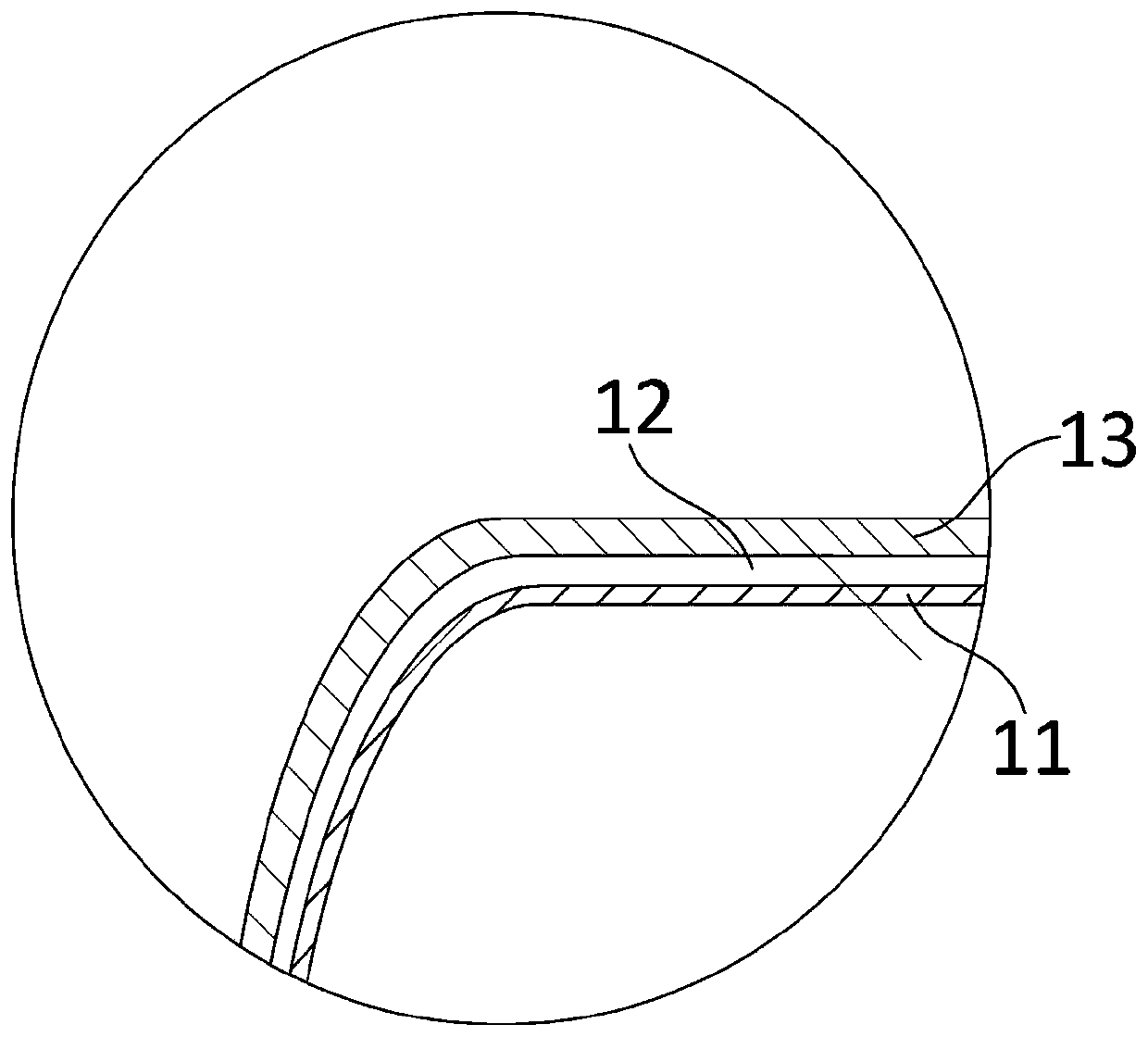

[0046] like Figure 1 to Figure 3 As shown, this embodiment provides a water storage water heater, which includes a water storage tank 1, a heating chamber 2 and a driving assembly, wherein a heating tube 4 is provided inside the heating chamber 2, and a water inlet is provided on the surface of the heating chamber 2. 21 and the water outlet 22, the water inlet 21 and the water outlet 22 are connected to the inside of the water storage tank 1; the driving assembly can drive the water in the heating chamber 2 to flow out from the water outlet 22; the shell structure of the water storage tank 1 includes the inner The inner container 11 on the surface is made of engineering plastics. Since the water storage water heater includes a separate heating chamber 2 and a driving assembly, the water in the heating chamber 2 can be heated first, and then the water in the heating chamber 2 can be combined with the water in the water storage tank 1 through the driving assembly. The way of c...

Embodiment 2

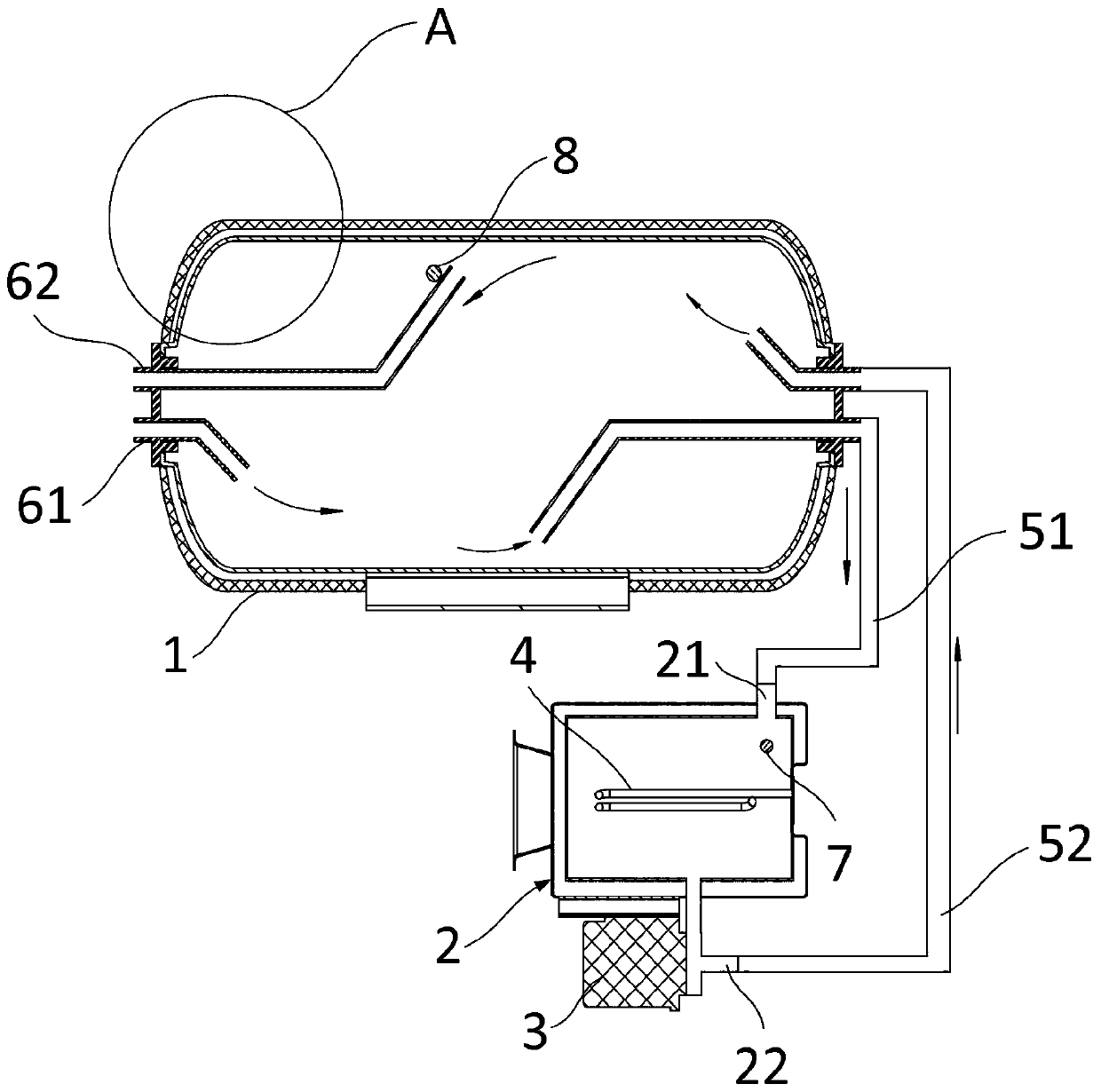

[0055] like Figure 4 to Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the heating chamber 2 of the water storage water heater is located in the water storage tank 1, and the heating chamber 2 is set as a sleeve structure with openings at both ends The water inlet 21 and the water outlet 22 of the heating chamber 2 are respectively located at the openings at both ends of the heating chamber 2 , and the driving assembly extends into the heating chamber 2 from the water inlet 21 of the heating chamber 2 . The heating chamber 2 is arranged inside the water storage tank 1, on the one hand, it can perform faster water circulation with the water storage tank 1; At the same time, the sleeve-shaped heating chamber 2 has a larger opening at the end, so it can be more conducive to the water circulation between the heating chamber 2 and the water storage tank 1, and accelerate heat exchange.

[0056] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com