Automated testing system for testing bearing performance of automobile

An automated testing, automotive bearing technology, applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as low testing efficiency, insufficient angle and torque control accuracy, and low degree of automation. Achieve the effect of flexible durability test, improved test efficiency and high degree of automation

Pending Publication Date: 2020-05-01

PHASE MOTION CONTROL SOLUTION WUHAN CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the traditional test system that controls the servo motor to test the performance of the bearing by means of PLC sending pulses, a torque sensor is required to test the torque of the load. In order to ensure the accuracy of the torque, a high-cost sensor is required, and the sensor passes The analog quantity is connected to the system. As the detection range increases, the accuracy will become worse and worse.

Therefore, the existing bearing testing system cannot meet the higher requirements of durability performance testing, the testing efficiency is low, the control accuracy of angle and torque is not high enough, and the degree of automation is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

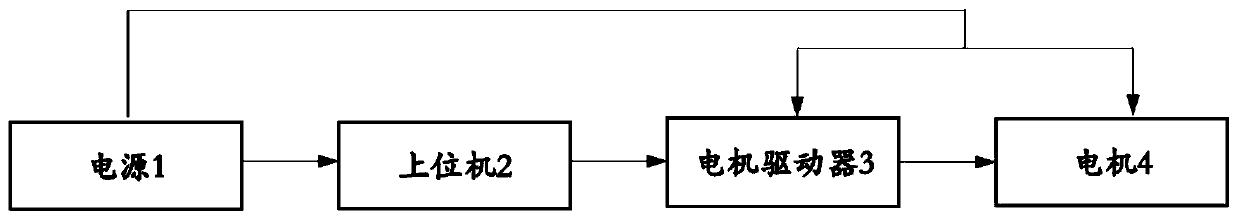

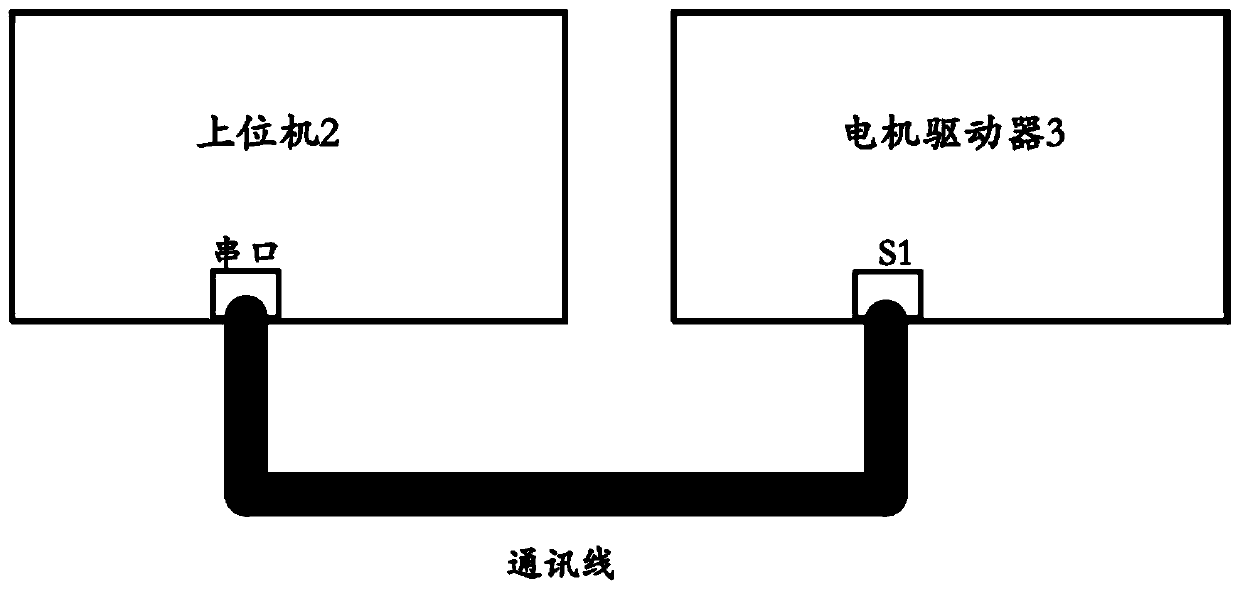

[0041] Embodiment one, as figure 1 As shown, an automated test system for automotive bearing performance testing, including a power supply 1, a host computer 2, a motor driver 3 and a motor 4;

[0042] The power supply 1 is electrically connected to the host computer 2 , the motor driver 3 and the motor 4 respectively, and the host computer 2 is electrically connected to the motor 4 through the motor driver 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

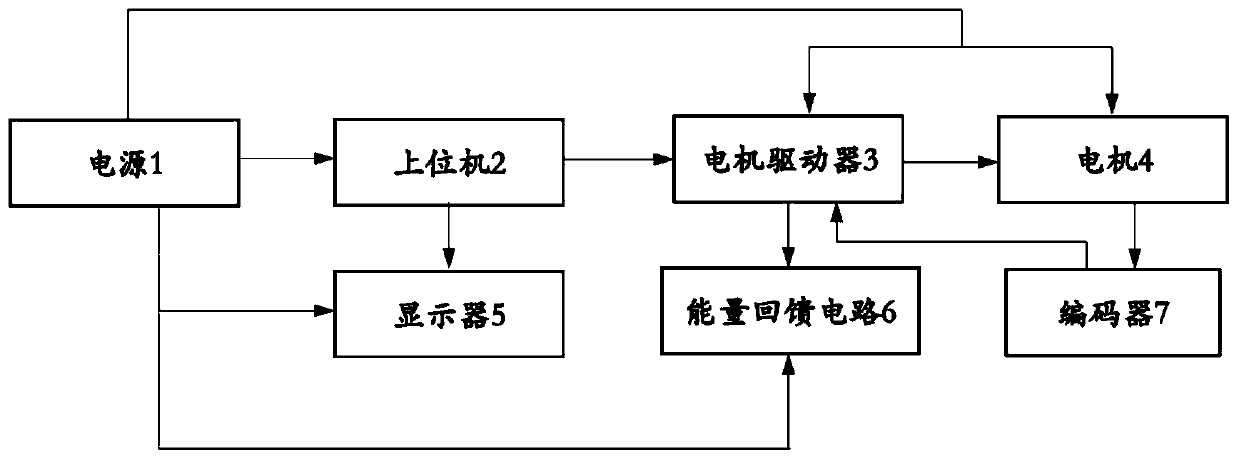

The invention relates to an automated testing system for testing bearing performance of an automobile. The automated testing system comprises a power supply, an upper computer, a motor driver and a motor, wherein the power supply is electrically connected with the upper computer, the motor driver and the motor separately; and the upper computer is electrically connected with the motor through themotor driver. According to the automated testing system, the upper computer issues system parameters and test tasks to the motor driver; and the motor driver drives the motor to run according to the system parameters and test tasks issued by the upper computer, thereby achieving automatic testing of the bearing performance. The automated testing system can meet the durability test conditions withhigher requirements; and compared with a traditional testing system for controlling a servo motor to test a bearing in a PLC pulsing mode, the automated testing system has the advantages that the testefficiency is greatly improved and the control accuracy on angles and torque is obviously improved.

Description

technical field [0001] The invention relates to the technical field of automobile safety and parts testing, in particular to an automatic testing system for performance testing of automobile bearings. Background technique [0002] As the people's demand for automobile safety increases, there are higher requirements for the performance of auto parts, which requires higher durability of auto parts, and the corresponding durability test also has higher requirements. . [0003] As a core component of auto parts, bearings cannot be ignored in the test of their durability. In order to better test the higher durability performance of bearings, the requirements for the corresponding testing system have also been significantly increased, including higher requirements for the testing efficiency of the testing system and the control accuracy of angle and torque. [0004] However, in the traditional test system that controls the servo motor to test the performance of the bearing by me...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/007G01M13/045

CPCG01M13/045G01M17/007

Inventor 杜佳成刘虎戴力杨彬杨合跃

Owner PHASE MOTION CONTROL SOLUTION WUHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com