Detection method for determining contents of niobium and tantalum in niobium-tantalum ore

A detection method and technology of niobium and tantalum, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of difficult operation, influence measurement, long process, etc., and achieve outstanding substantive characteristics, significant progress, The operation process is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

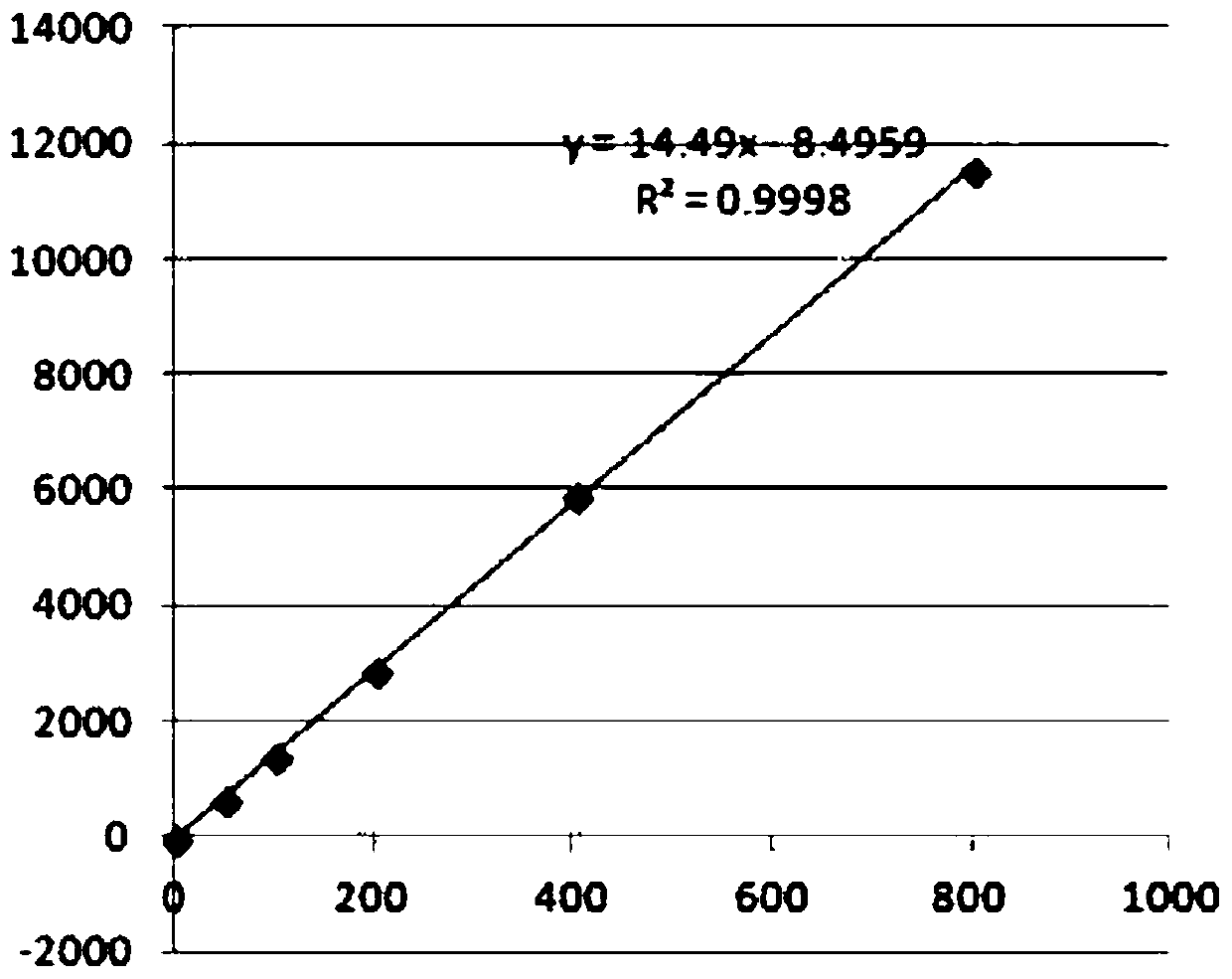

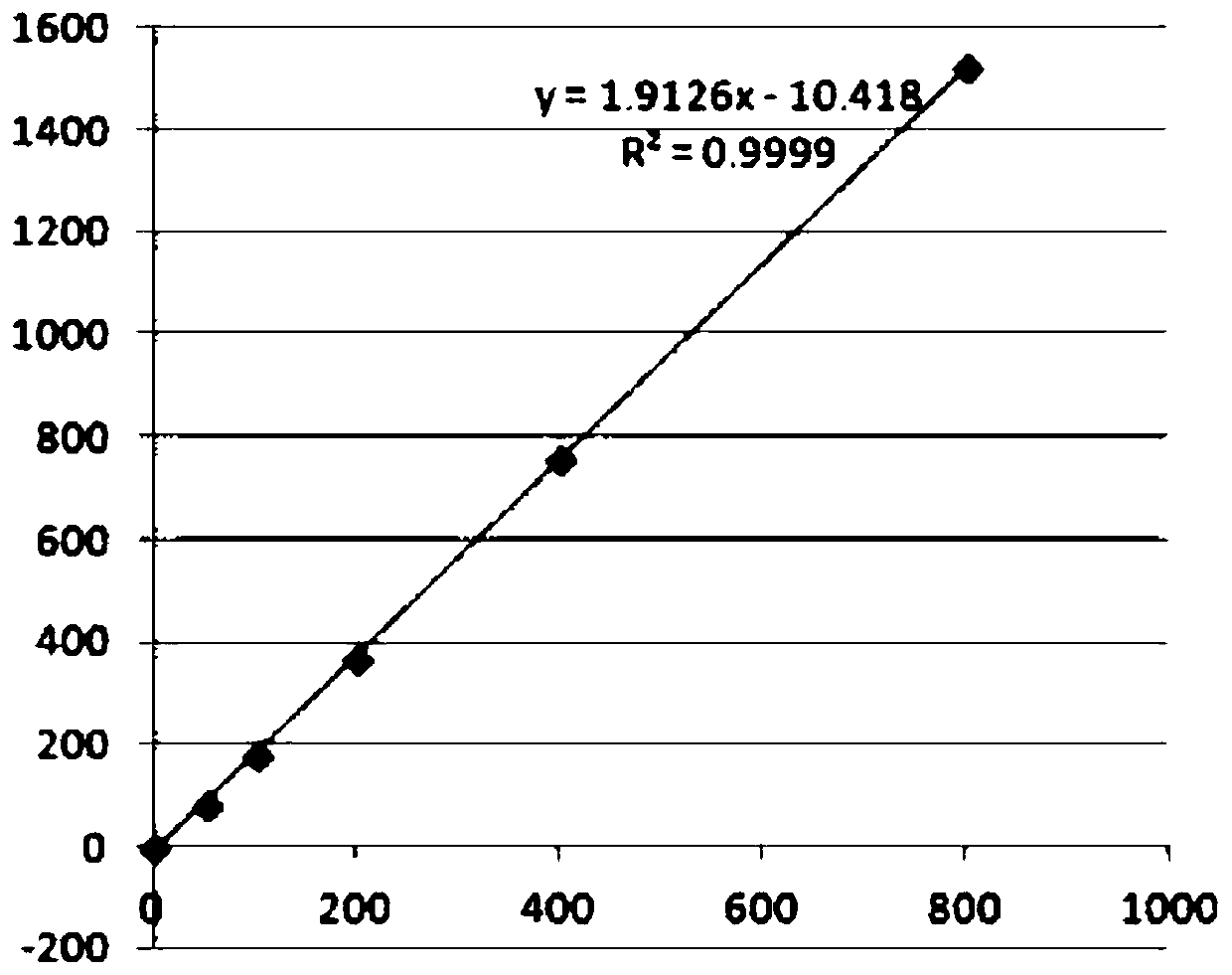

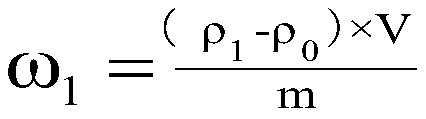

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0026] A detection method for measuring niobium and tantalum content in niobium-tantalum ore, which comprises the following steps:

[0027] (1) Accurately weigh 0.2g of niobium-tantalum ore sample that has been dried at 101°C-105°C, place the sample in a 100mL polytetrafluoroethylene beaker, and wet it with 2-3mL deionized water;

[0028] (2) Add 8-10mL of nitric acid with a concentration of 1.40g / mL, 0.5-1mL of perchloric acid with a concentration of 1.66g / mL, and 8-10mL of hydrofluoric acid with a concentration of 1.13g / mL into a polytetrafluoroethylene beaker. acid, and shake it gently, rinse the wall of the cup with 2-3mL deionized water, place the polytetrafluoroethylene beaker on an electric heating plate at 180°C-220°C and heat it to decompose;

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com