Full-automatic environment-friendly briquetting device for fibrous materials

A fully automatic, fibrous technology, applied in biofuels, waste fuels, material forming presses, etc., can solve the problems of large storage and transportation space, scattered and scattered fibers, and high transportation costs, so as to reduce transportation costs and Occupational injury and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

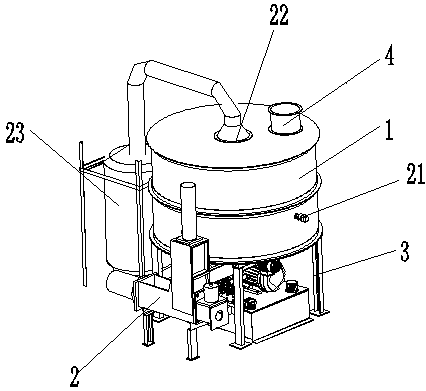

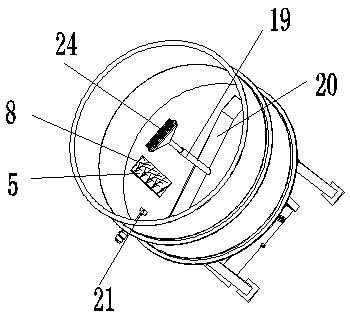

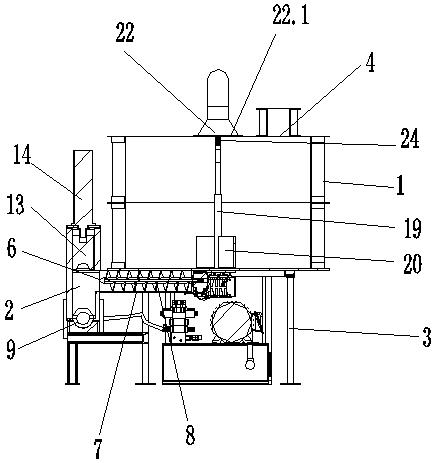

[0026] Example 1: Such as figure 1 , 2 , 3, 4, 5, 6, a fully automatic environmental protection briquetting device for fibrous materials, including a storage bin 1 and a pressurizing box 2. The storage bin 1 has a cylindrical structure, and the bottom of the storage bin 1 is provided with Feet 3, the storage bin 1 is provided with a feeding port 4, the bottom of the storage bin 1 is provided with a blanking port 5, the side wall of the pressurizing box 2 is provided with a feeding port 6, and the blanking port 5 and the feeding port 6 pass through The connecting pipe 7 is connected, the connecting pipe 7 is provided with a screw auger 8, the bottom of the pressurizing box 2 is sealed by a mandrel sleeve 9, and the mandrel sleeve 9 is connected to the foot 3 through a bracket 25. The outer wall of the ejector sleeve 9 is provided with a ring Groove 26, the bracket 25 is provided with a convex block 27 that is inserted into the annular groove, the side wall of the ejector sleeve 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com