Electronic tag and manufacturing method thereof

An electronic label and flexible circuit board technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of shortened reading and writing distance, poor label performance, single function of electronic labels, etc., to prevent transfer Use, not easy to break, improve the effect of metal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

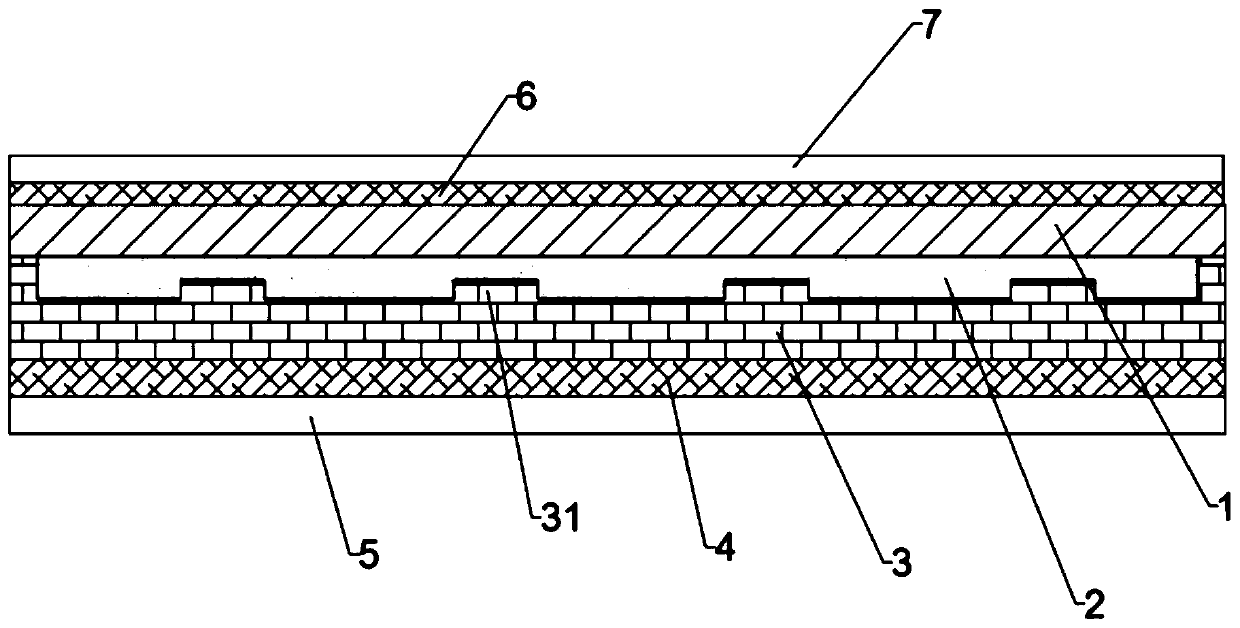

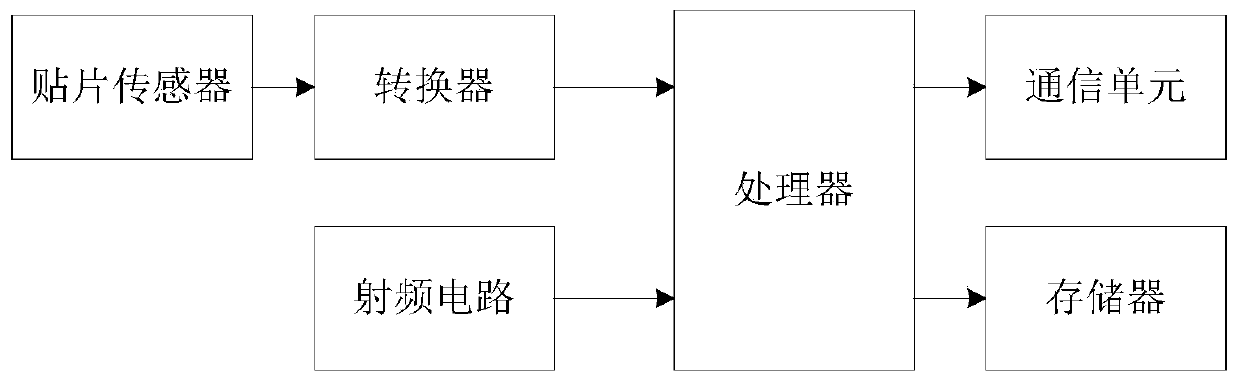

[0020] Such as figure 1 with figure 2 As shown, an electronic label includes a release paper layer 5, a second adhesive layer 6, an anti-metal material layer 3, a chip layer 1, a second adhesive layer 6 and a fragile paper layer 7 arranged in sequence, and the anti-metal Material layer 3 adopts PET polyethylene terephthalate or PI polyimide. The first adhesive layer and the second adhesive layer use pressure-sensitive hot melt adhesive or pressure-sensitive adhesive. The side of the anti-metal material layer 3 opposite to the chip layer 1 is provided with a number of grooves 31, and a silicone oil layer 2 is provided between the groove surface 31 and the chip layer 1. The chip layer 1 adopts a flexible circuit board, and the flexible circuit board is provided with a processing The chip sensor, the radio frequency circuit and the communication unit are respectively connected with the processor, and the radio frequency circuit is etched on the flexible circuit board by using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com