System and method for multi-battery pack parallel discharge operation

A technology for operating systems and battery packs, which is applied in the charging/discharging of secondary batteries, the arrangement of multiple synchronous batteries, and battery circuit devices, etc., can solve the problem that multiple battery packs cannot be operated in parallel with hot backup and redundancy at the same time. Clear principle, good performance in the full parameter range, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

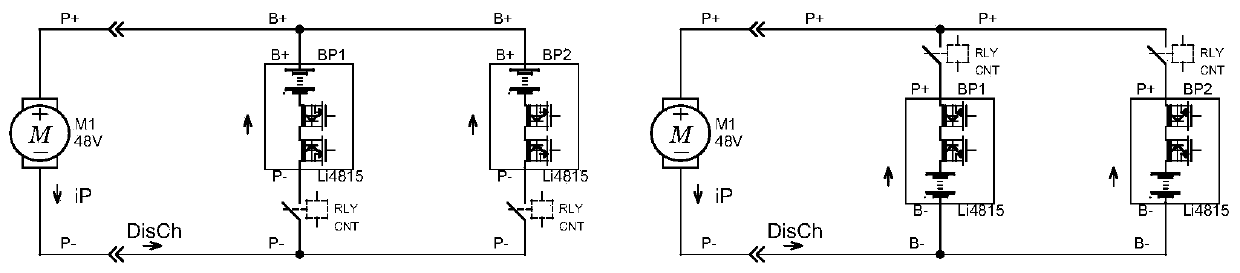

[0138] Such as Figure 9 Shown is the system embodiment 1 of the parallel discharge operation of multiple battery packs of the present invention, and the system includes:

[0139] A parallel discharge system is composed of controlled electrical battery pack BRPi, i=1~2;

[0140] All positive poles of the battery pack are connected to P+, and all negative poles are connected to P-;

[0141] The BPC serial port is empty, the battery pack address status SAD port is suspended, and the internal inspection is in discharge mode;

[0142] The effective discharge working range of the battery pack further includes:

[0143] Nominal voltage: Vnom=48.0V, (+16.7%, -12.5%) Vnom;

[0144] Nominal range: upper limit Vnup=56.0V, lower limit Vnlp=42.0V;

[0145] Friendly application: upper bound Vnua=51.0V, lower bound Vnla=45.0V, ±(4-7)%;

[0146] The default preset voltage Vset1=54.6V, the pre-set voltage Vset0=56.0V;

[0147] Selected power system load controller rated specification: 4...

Embodiment 2

[0156] Such as Figure 10 Shown is the system embodiment 2 of the parallel discharge operation of multiple battery packs of the present invention, and the system includes:

[0157] A parallel discharge system is composed of controlled electrical battery packs BRPi, i=1~3;

[0158] All positive poles of the battery pack are connected to P+, and all negative poles are connected to P-;

[0159] Select the monitor and all battery packs, connect BPCs and SADs;

[0160] Select the monitor and all battery packs, connect resistance Ri in series between BH and SAD;

[0161] The effective discharge working range of the selected system and battery pack further includes:

[0162] Nominal voltage: Vnom=48.0V, (+16.6%, -12.5%) Vnom;

[0163] Nominal range: upper limit Vnup=56.0V, lower limit Vnlp=42.0V;

[0164] Friendly application: upper bound Vnua=51.0V, lower bound Vnla=45.0V, ±(4-7)%;

[0165] Default preset voltage Vset1=54.6V;

[0166] Selected power system load controller rat...

Embodiment 3

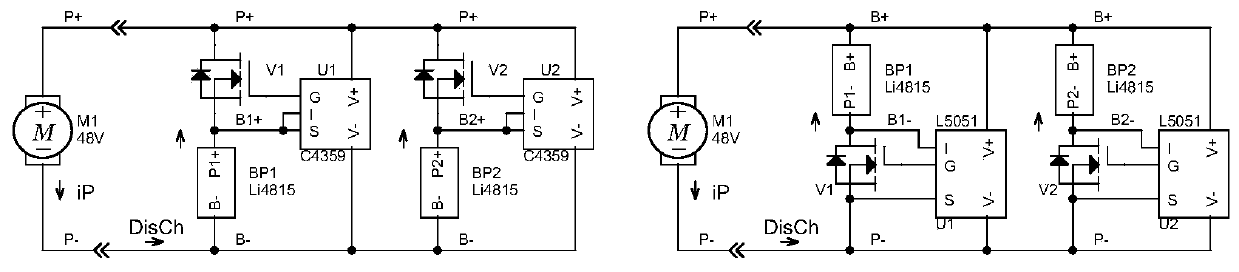

[0177] Such as Figure 11 Shown is the system embodiment 3 of the multi-battery pack parallel discharge operation of the present invention, the system includes:

[0178] A parallel discharge system is composed of controlled electrical battery pack BRPi, i=1~12;

[0179] All positive poles of the battery pack are connected to P+, and all negative poles are connected to P-;

[0180] Select the monitor and all battery packs, connect between BPC and Sbus;

[0181] Select all battery packs, and connect resistor Ri in series between P+ and SAD;

[0182] The effective discharge working range of the selected system and battery pack further includes:

[0183] Nominal voltage: Vnom=48.0V, (+16.6%, -12.5%) Vnom;

[0184] Nominal range: upper limit Vnup=56.0V, lower limit Vnlp=42.0V;

[0185] Friendly application: upper bound Vnua=51.0V, lower bound Vnla=45.0V, ±(4-7)%;

[0186] Default preset voltage Vset1=54.6V;

[0187] Preset voltage Vset0=56.0V for excellent amplifier, Vset2=5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com