Processing technology for spicy dry-dried chicken, and spicy air-dried chicken prepared from processing technology

A processing technology, air-dried chicken technology, applied in the direction of climate change adaptation, food science, etc., can solve the problems of flavor and quality degradation, and achieve high production efficiency, short production cycle, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A kind of spicy air-dried chicken processing technology comprises the following steps,

[0072] S1: The white striped chicken is thawed by running water, and the white striped chicken is thawed. After thawing, it is graded and selected according to weight.

[0073] White-striped chicken with a net weight of less than 1.2kg is the first grade,

[0074] White-striped chicken with a net weight of 1.2-1.5kg is the second grade.

[0075] White-striped chicken with a net weight of 1.5-2.0kg is the third grade.

[0076] and cleaned;

[0077] S2: The white striped chicken that has been selected and graded and cleaned, here is the second graded white striped chicken, put into the old soup prepared in advance, soaked in the old soup at 2°C and marinated for 24 hours. The old soup consists of salt, sugar, star anise , Zanthoxylum bungeanum, and chili natural spices are boiled and cooled. The ratio of the old soup can be determined according to the actual production formula. Her...

Embodiment 2~6

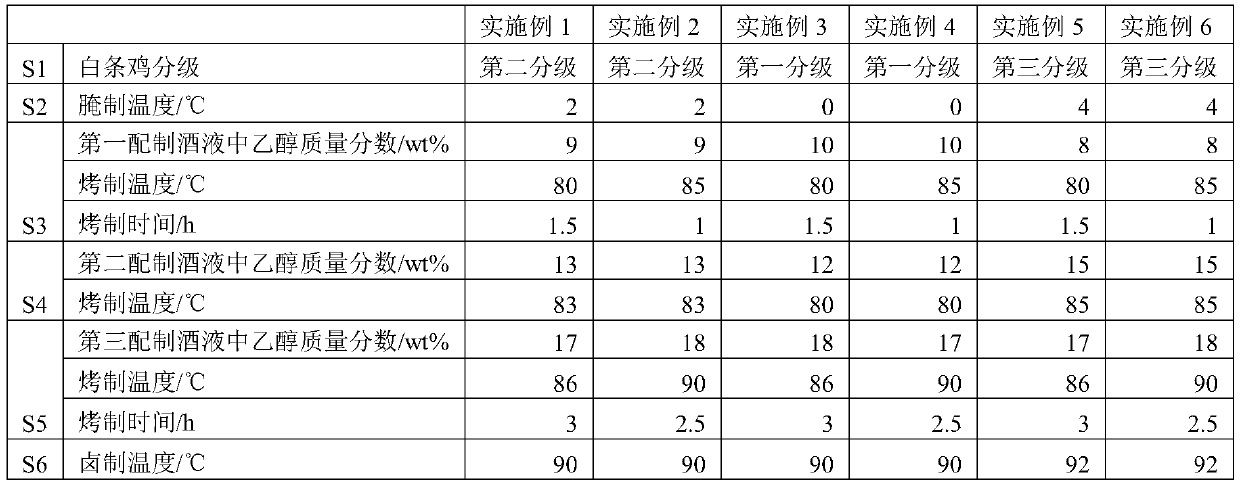

[0102] A processing technology for spicy air-dried chicken, based on Example 1, the difference lies in the adjustment of process parameters in the processing process, and the spicy air-dried chicken of Examples 2-6 are finally obtained. Embodiment 1 and Embodiment 2~6 active mobilization process parameters are listed in the following Table 1.

[0103] Table I

[0104]

Embodiment 7

[0138] A processing technology for spicy air-dried chicken, based on Example 1, the difference lies in that the first prepared wine liquid is replaced by white wine.

[0139] Comparing the flavors of the spicy air-dried chicken of Example 1 and Example 7, the spicy air-dried chicken of Example 1 has the fragrance of rice wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com