Cleaning machine

A washing machine and washing chamber technology, which is applied in the field of washing machines, can solve the problems of large welding deformation, high cost, and large installation space, and achieve the effects of preventing deformation due to cold and heat, reducing production costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

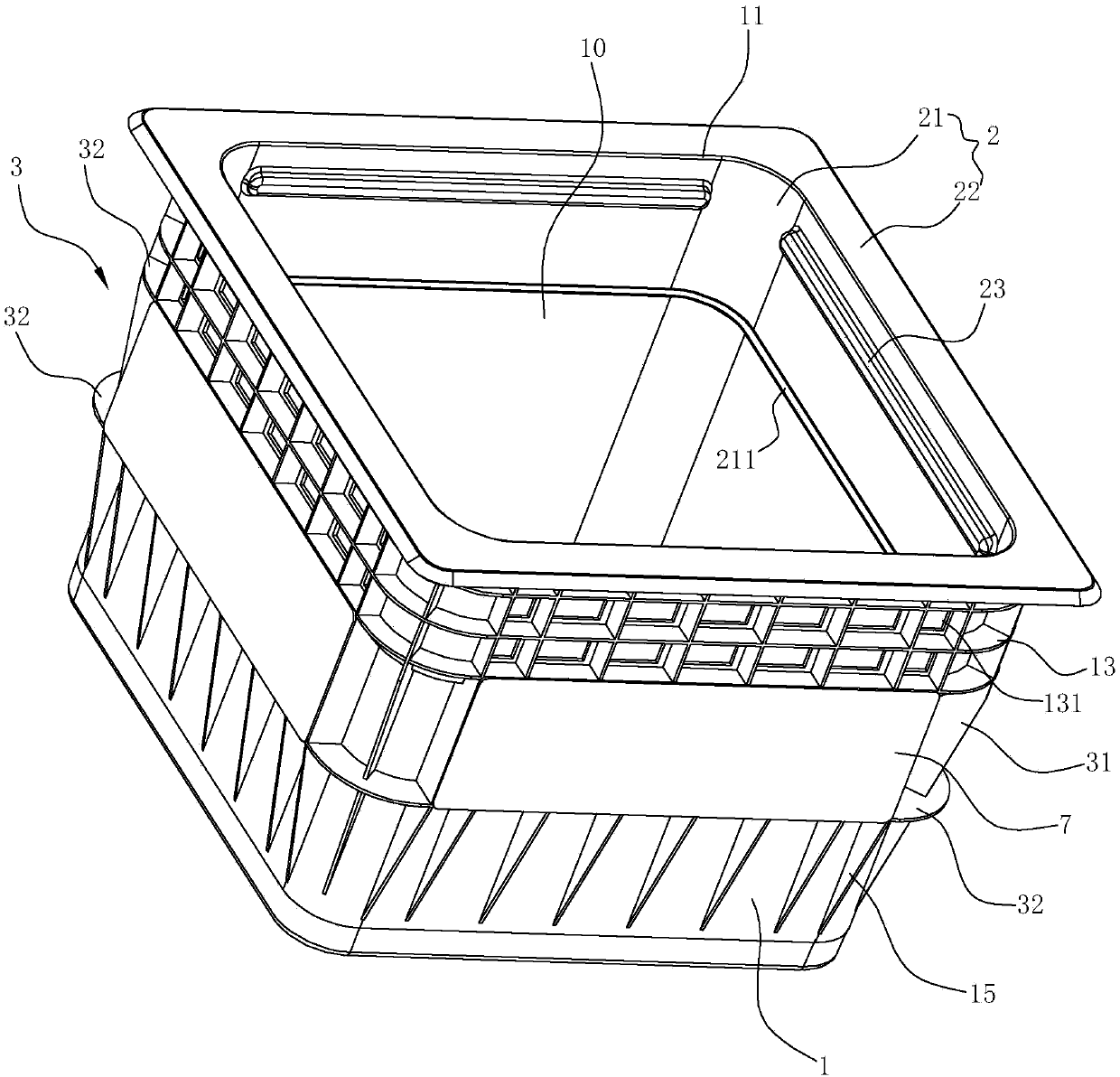

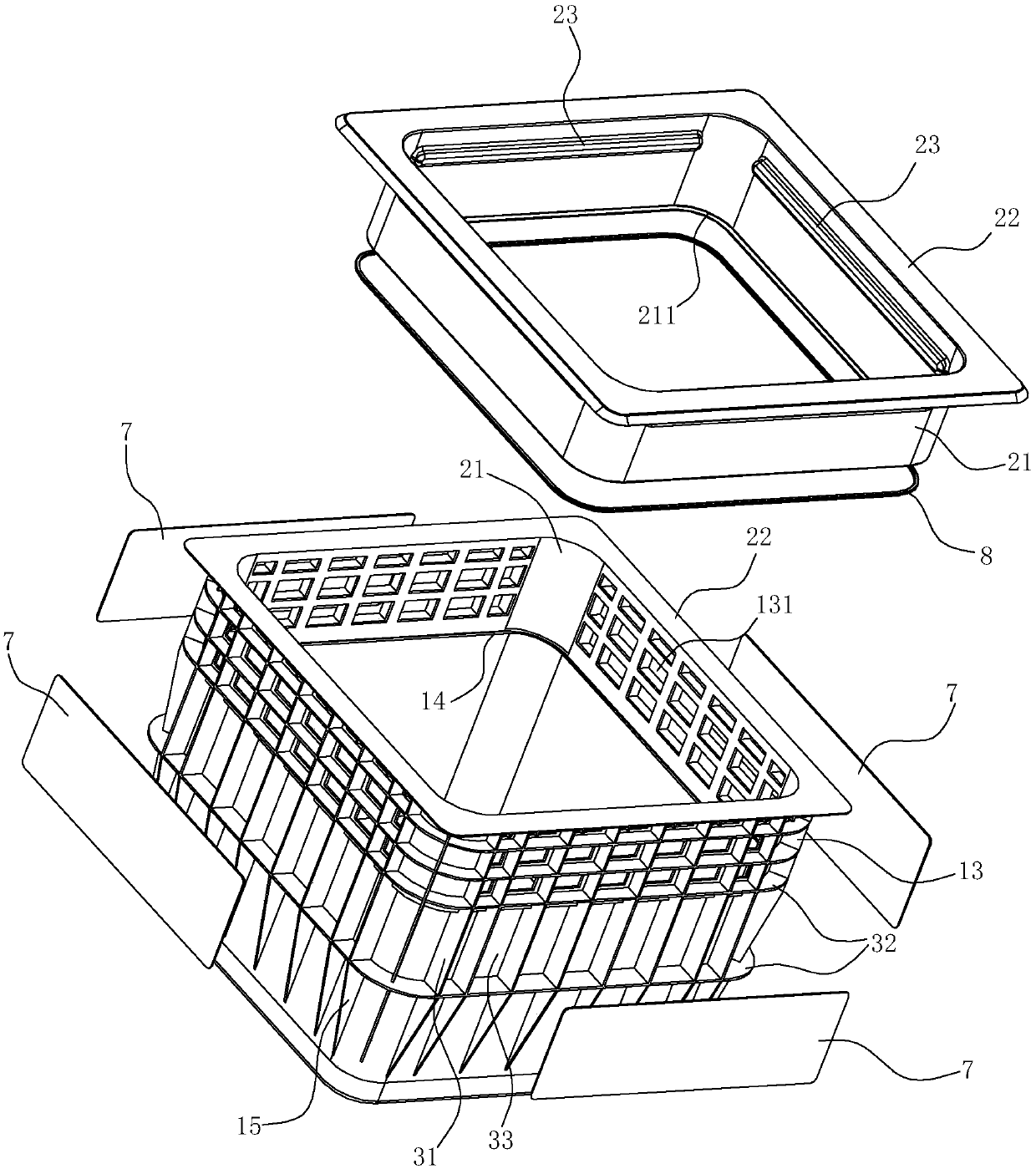

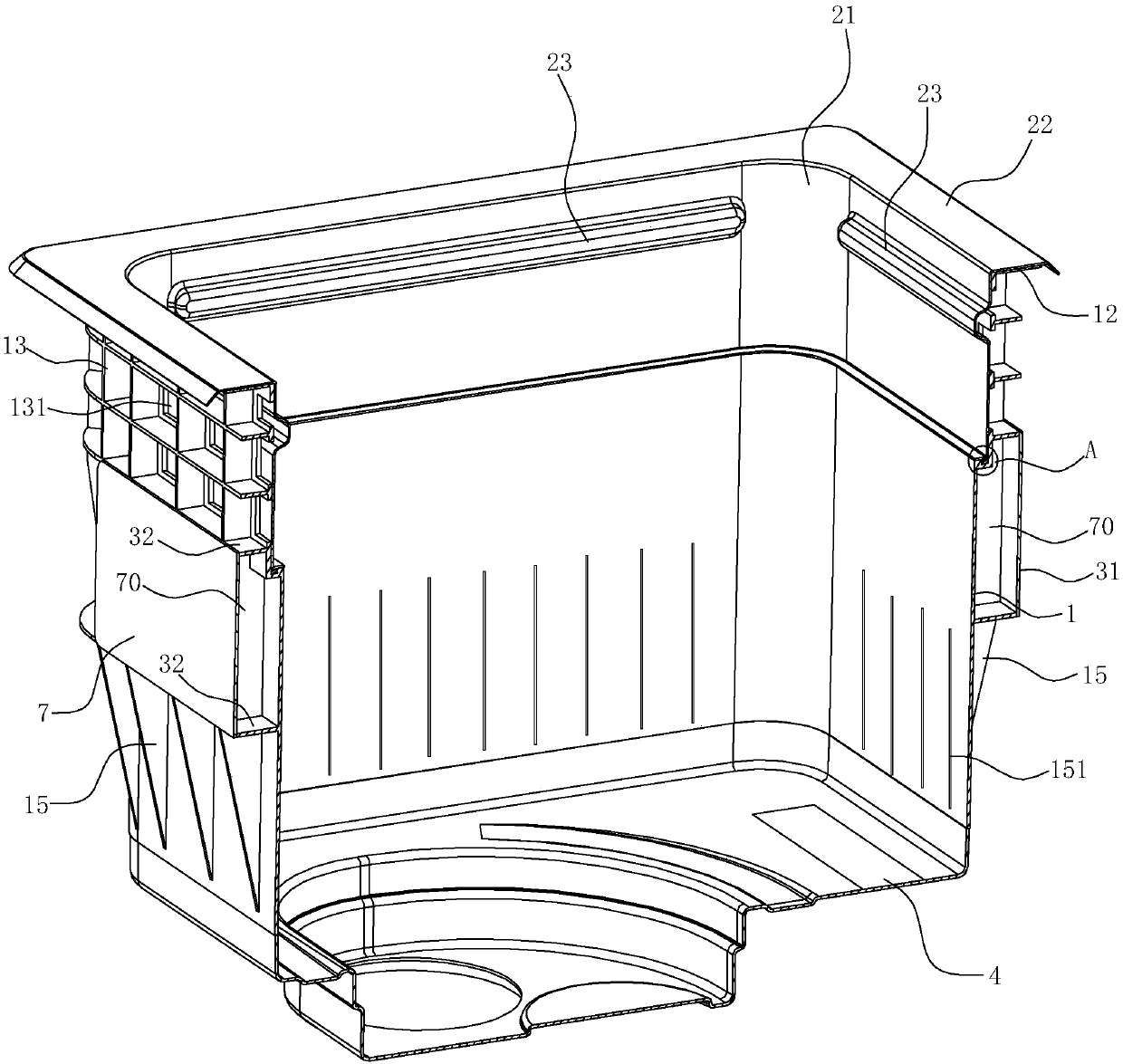

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] Such as Figure 1~5 As shown, the cleaning machine in this embodiment is a sink type cleaning machine, including a sink body 1 with a washing cavity 10, the sink body 1 needs to be installed on the cabinet table for use, and there is an installation port for installing the sink body 1 on the cabinet table . The top of the sink body 1 has an opening 11 that communicates with the washing chamber 10, and the edge of the opening 11 extends outwards to form a shelf 12 that can rest on the countertop of the cabinet.

[0026] The bottom of the water tank body 1 in this embodiment is provided with a water pump capable of lifting water from the bottom of the water tank body 1 and spraying upwards through the spray arm. The bottom of the sink body 1 is provided with an ultrasonic generator 4, which structure can effectively improve the cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com