Vehicle-mounted ex-situ direct thermal desorption system and application method thereof

A thermal desorption, vehicle-mounted technology, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of tight repair schedule and low repair cost, and achieve compact structure design, shortened installation time, and fast processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings.

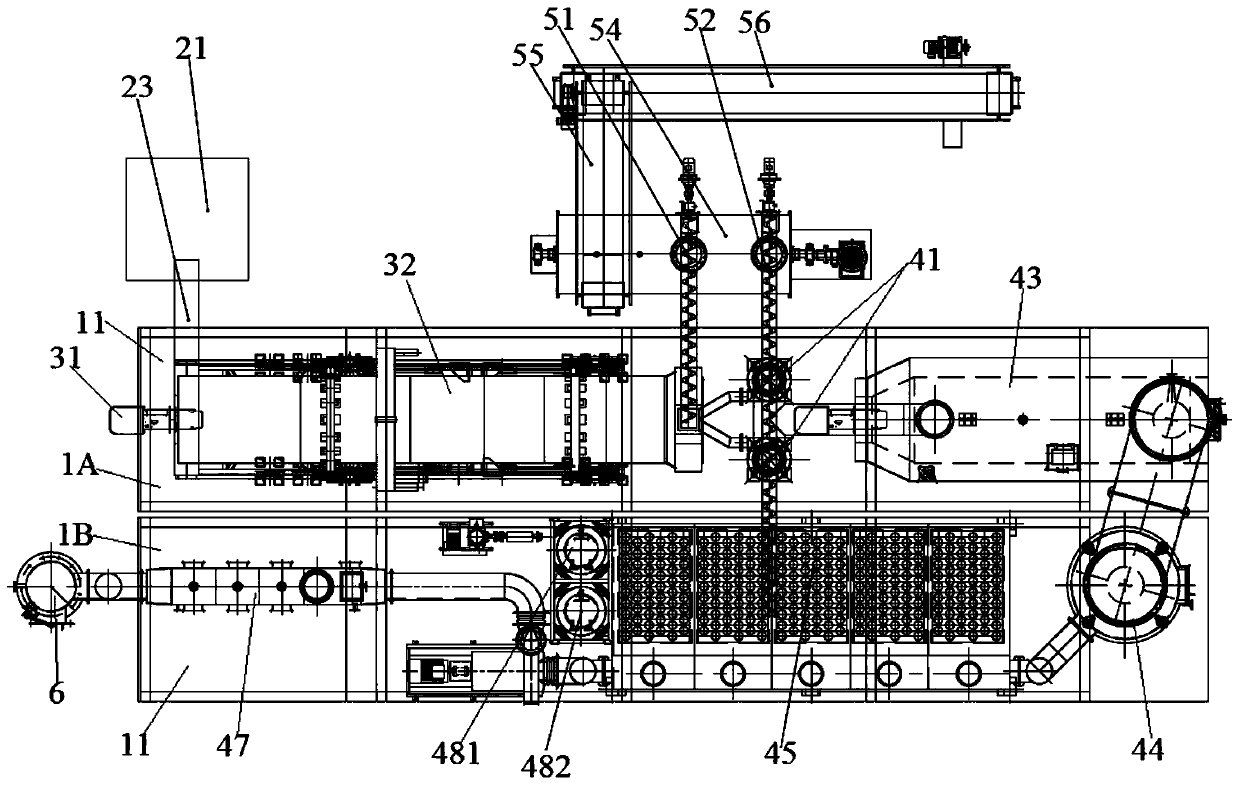

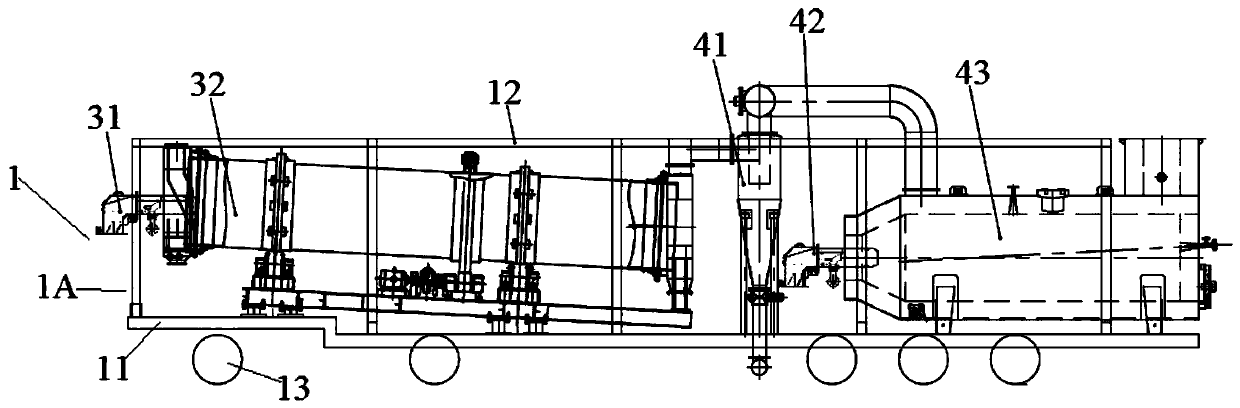

[0064] Figure 1-14 A vehicle-mounted ex-situ direct thermal desorption system according to an embodiment of the present invention is schematically shown.

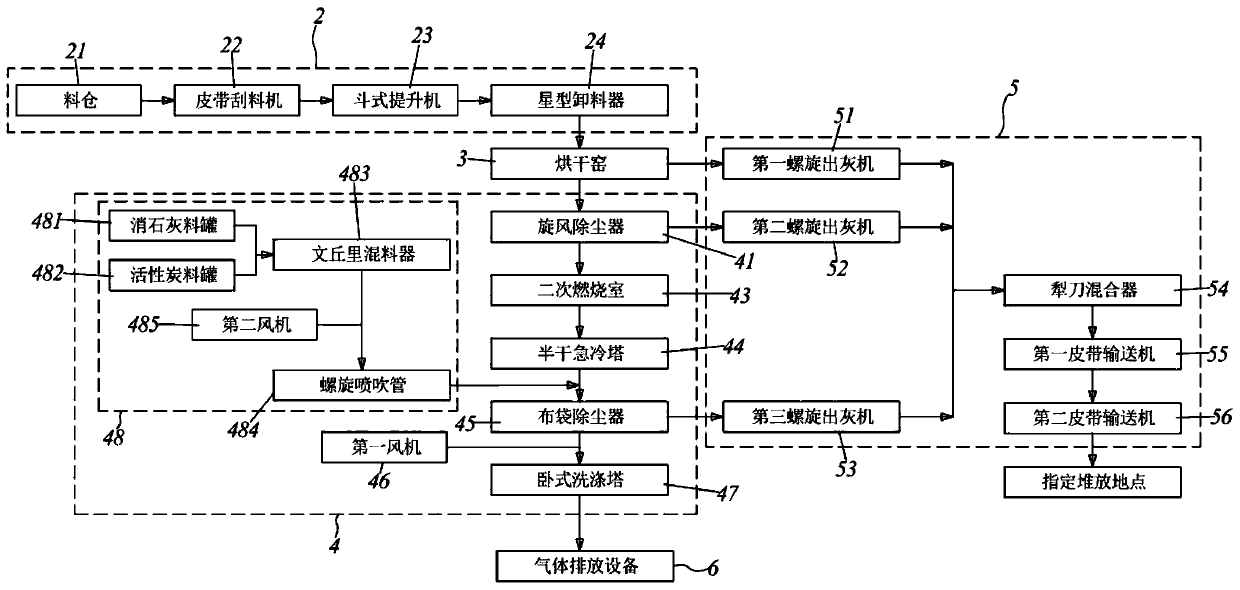

[0065] Such as Figure 1-14 As shown, the vehicle-mounted ex-situ direct thermal desorption system includes a transport vehicle 1 , feeding equipment 2 , drying kiln equipment 3 , flue gas treatment equipment 4 , discharging equipment 5 and gas discharge equipment 6 .

[0066] The transport vehicle 1 of the present embodiment can adopt a flat-bed transport vehicle 1 commonly used in the market, and the front end and the flat-bed vehicle body can be separated after being transported in place. The transport vehicle 1 in this embodiment includes a load base 11 , wheels arranged at the bottom of the load base 11 , and an integrated maintenance platform 12 set above the load base 11 . The drying kiln equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com