Hub die-casting molten aluminum anti-overflow device

A technology of anti-running and wheel hubs, which is applied in the field of wheel hub manufacturing, can solve the problems of threatening the safety of workers, damage to mold peripheral equipment, burns, etc., and achieve the effects of ensuring equipment safety, reducing the spraying range and reducing the spraying energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

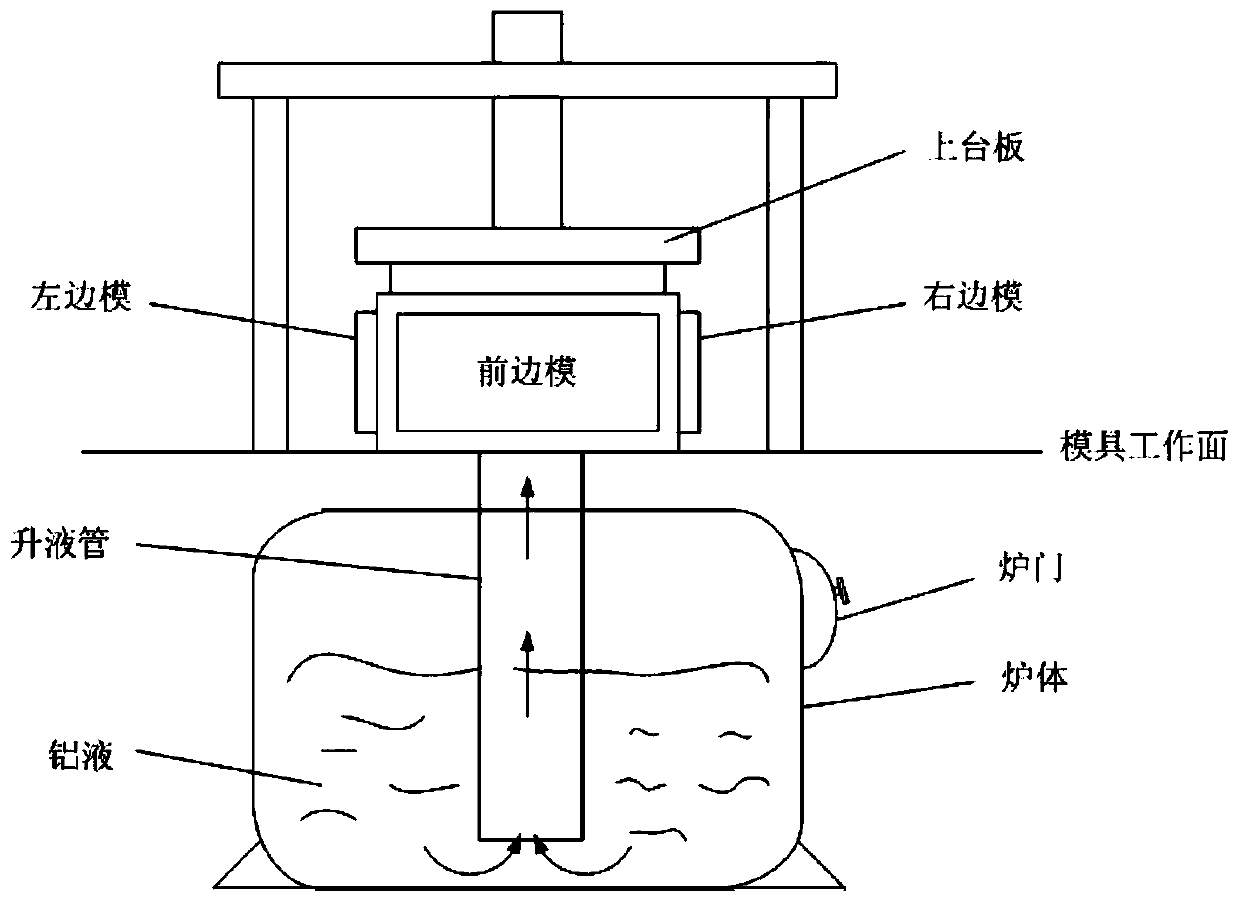

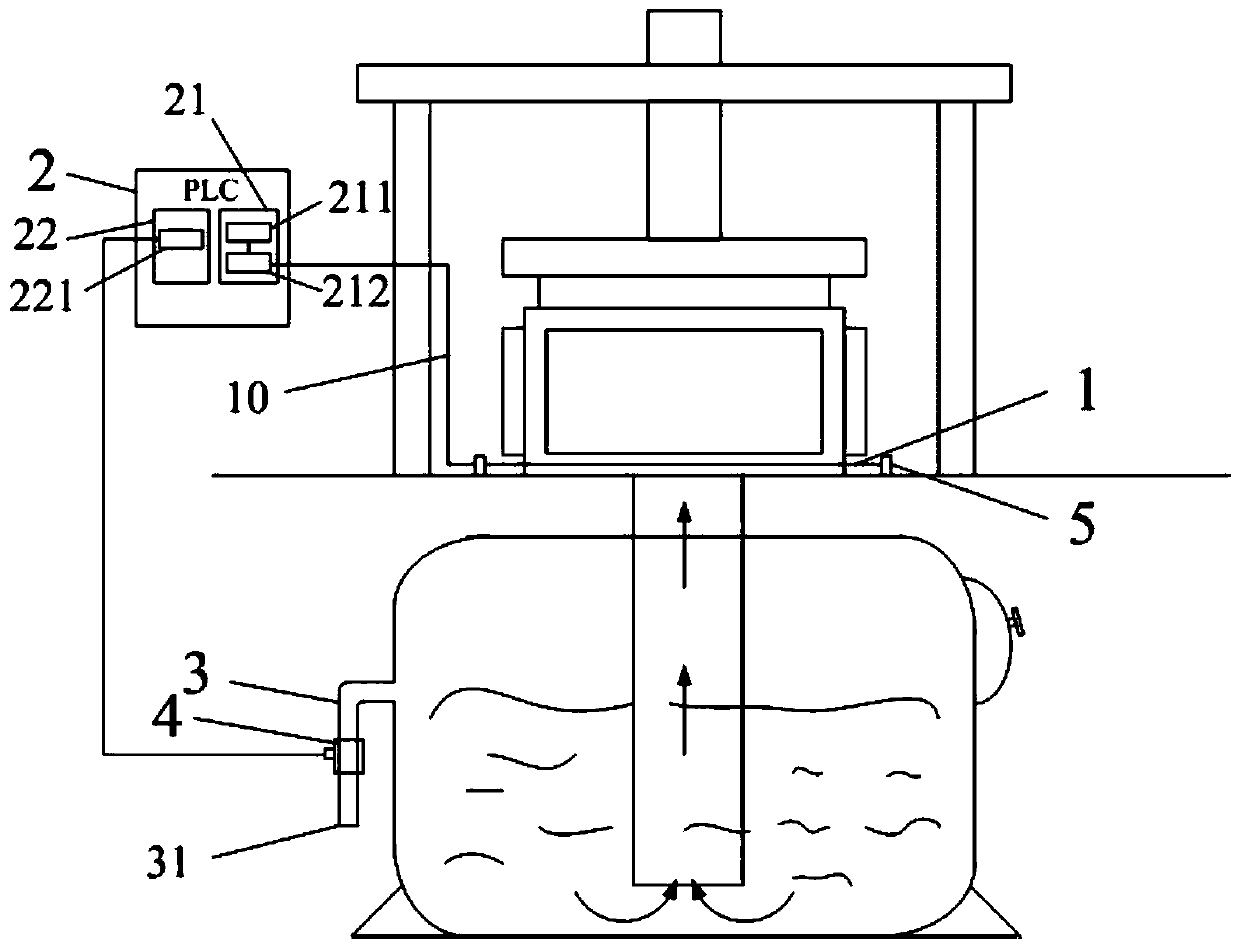

[0024] The invention provides a wheel hub die-casting anti-run aluminum liquid device, such as figure 2 As shown, it includes anti-running aluminum wire 1, PLC module 2, furnace body exhaust pipe 3 and furnace body exhaust valve 4, wherein:

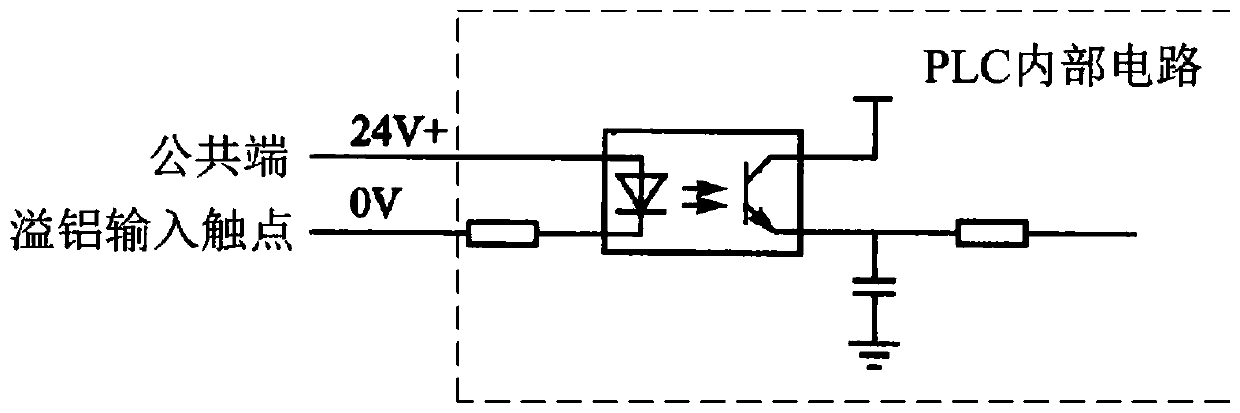

[0025] The anti-running aluminum wire 1 is a wire with insulation, the input terminal 21 of the PLC module 2 is provided with a common terminal 211 and an aluminum overflow input contact 212, and the output terminal 22 of the PLC module 2 is provided with an aluminum overflow pressure relief contact 221, one end of the furnace body exhaust pipe 3 is connected to the furnace body, the other end of the furnace body exhaust pipe 3 is provided with an exhaust port 31, and the furnace body exhaust valve 4 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com