Combustible cartridge case cutting machine

A divider and cartridge technology, applied in metal processing, sampling devices, etc., can solve problems such as affecting the accuracy of physical and chemical tests, easy spillage of propellants, flammable safety risks, etc., to achieve easy removal, stable work, and avoid spillage. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

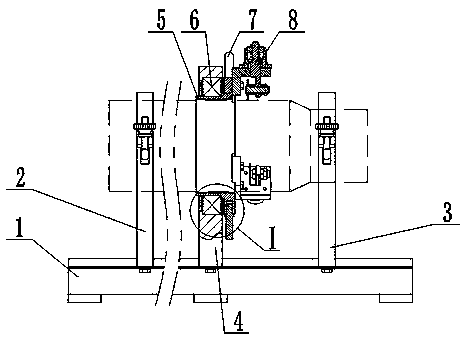

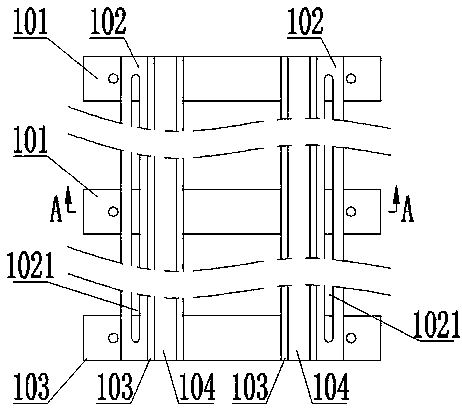

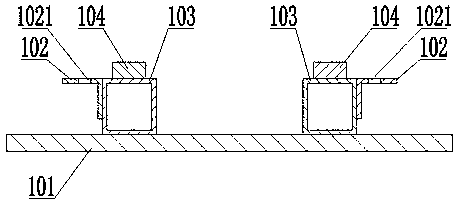

[0032] Such as figure 1 , Figure 10 As shown, a combustible cartridge dividing machine of the present invention includes a support 1, a large support 2, a small support 3, a bearing support 4, a dividing coil 5, a bearing 6 and a dividing assembly 8, a large support 2, a small support 3 and The bearing support 4 is slidingly connected to the bracket 1, the large support 2 and the small support 3 are respectively arranged on the front and rear sides of the bearing support 4, the split coil 5 is rotatably connected to the bearing support 4, and the bearing 6 is connected to the bearing support Between 4 and the divided coil 5, the bearing support 4 is provided with a bearing hole 401, the bearing 6 is connected in the bearing hole 401, the divided coil 5 includes a connecting pipe 501 and a flange 502, and the connecting pipe 501 is connected in the bearing 6, The flange 502 stretches out from the bearing support 4, and the split assembly 8 is connected to the flange end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com