Preparation device and method for large-size heat adaptation structure of carbon fiber yarns

A carbon fiber filament and preparation device technology, applied in manufacturing tools, punching machines, presses, etc., can solve the problems of inability to completely eliminate thermal deformation, limited material selection range, detector warpage deformation, etc., and achieve thermal mismatch deformation. , The effect of simple structure and small flexural section modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The device for preparing carbon fiber thermally adapted structure of the present invention uses a metal mold to press and compress carbon fibers. The pressure can be adjusted so that the carbon fibers can be compressed without too much pressure and the carbon fibers are not damaged. The structure is simple and the implementability is good.

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

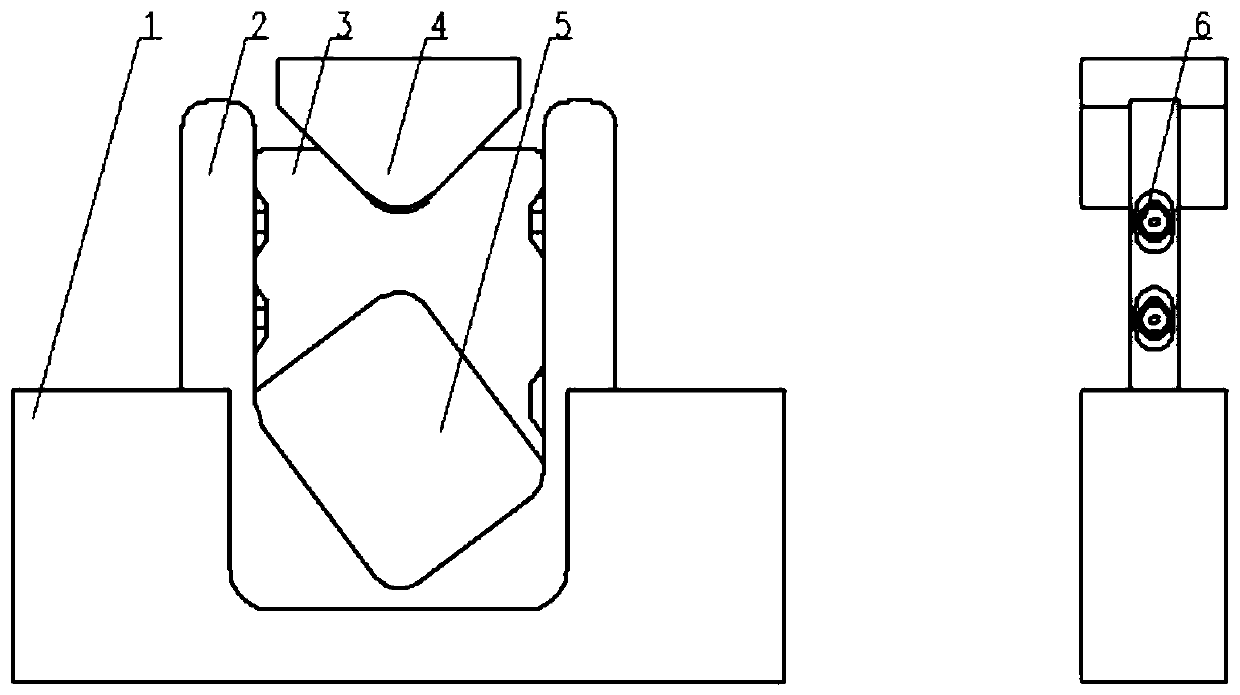

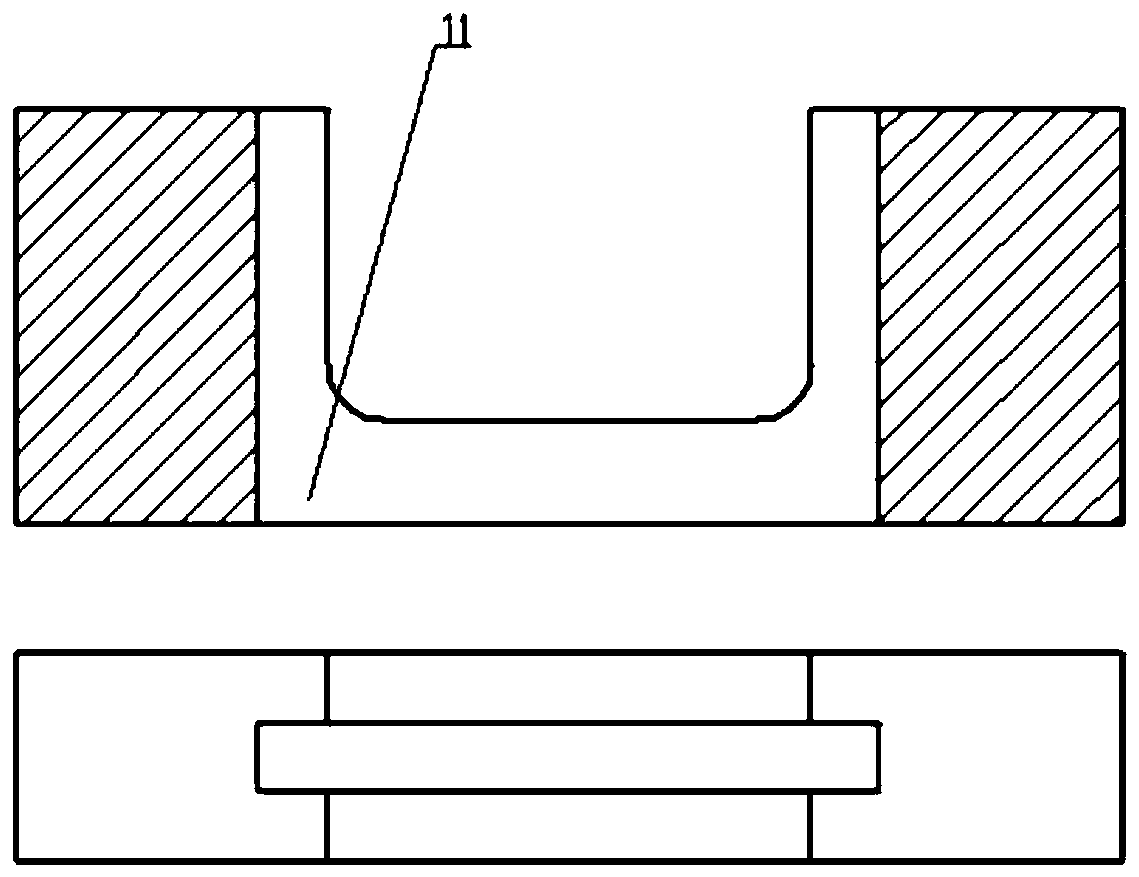

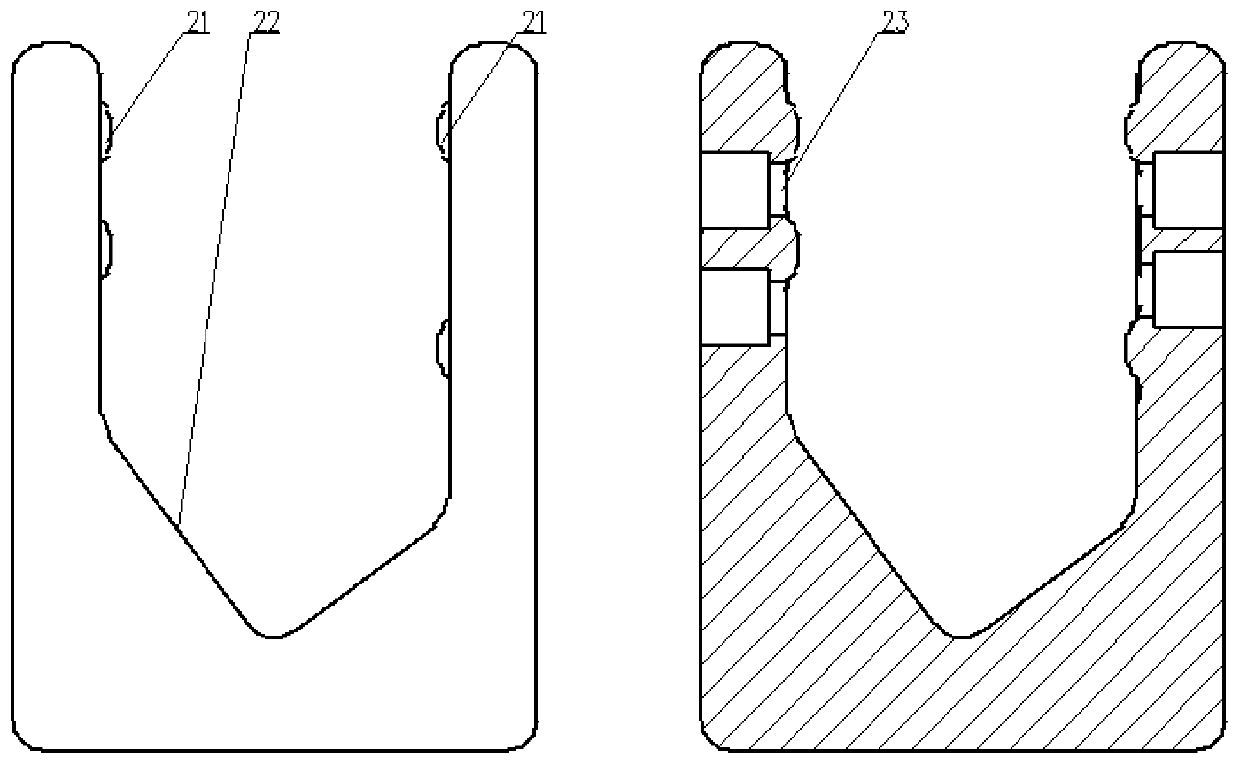

[0028] Such as figure 1 As shown, the present invention is a preparation device for a large-size thermally adapted structure of carbon fiber filaments, including: a base 1 , a fixing block 2 , a pressing slider 3 , a pressure plate 4 , carbon fiber filaments 5 and screws 6 . The base 1 is placed on the platform, the fixed block 2 is installed in the slot 11 of the base 1, and the carbon fiber filament 5 is placed in the right-angled opening 22 of the fixed block 2. The carbon fiber filament...

Embodiment

[0043] According to the preparation device of the large area array detector thermal adaptation structure based on carbon fiber of the present invention, a carbon fiber filament thermal adaptation structure with a length of 50mm, a width of 40mm, and a thickness of 5mm has been successfully prepared, and the thermal adaptation structure glues the detector on the cold On the finger, under the temperature fluctuation of about 200K, the thermal deformation and warpage of the detector is only 3um, which solves the problem of thermal mismatch deformation between the large area array detector and the cold finger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com