Environment-friendly clothing packaging film and preparation method thereof

A packaging film, an environment-friendly technology, applied in the field of environment-friendly clothing packaging film and its preparation, can solve problems such as the impact of clothing sales, achieve the effects of improving anti-ultraviolet aging performance, increasing antibacterial ability, and facilitating opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

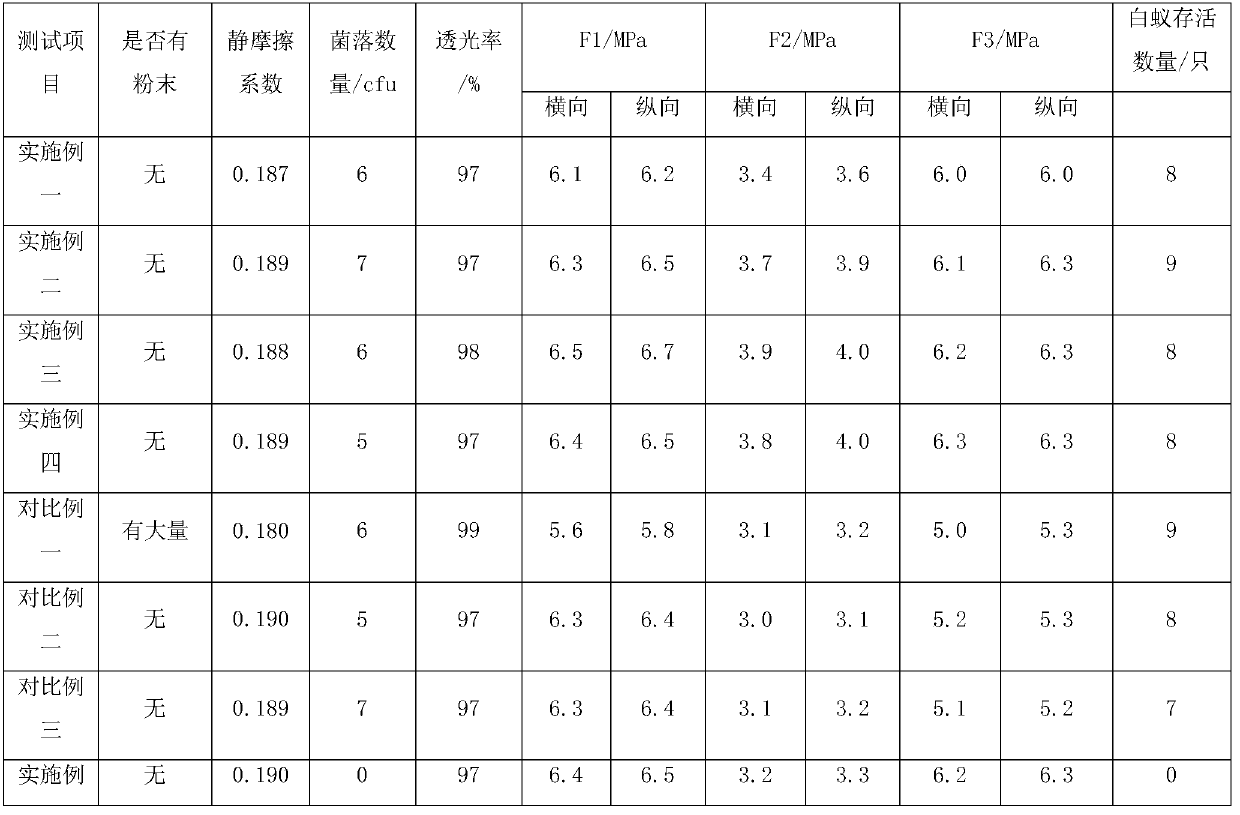

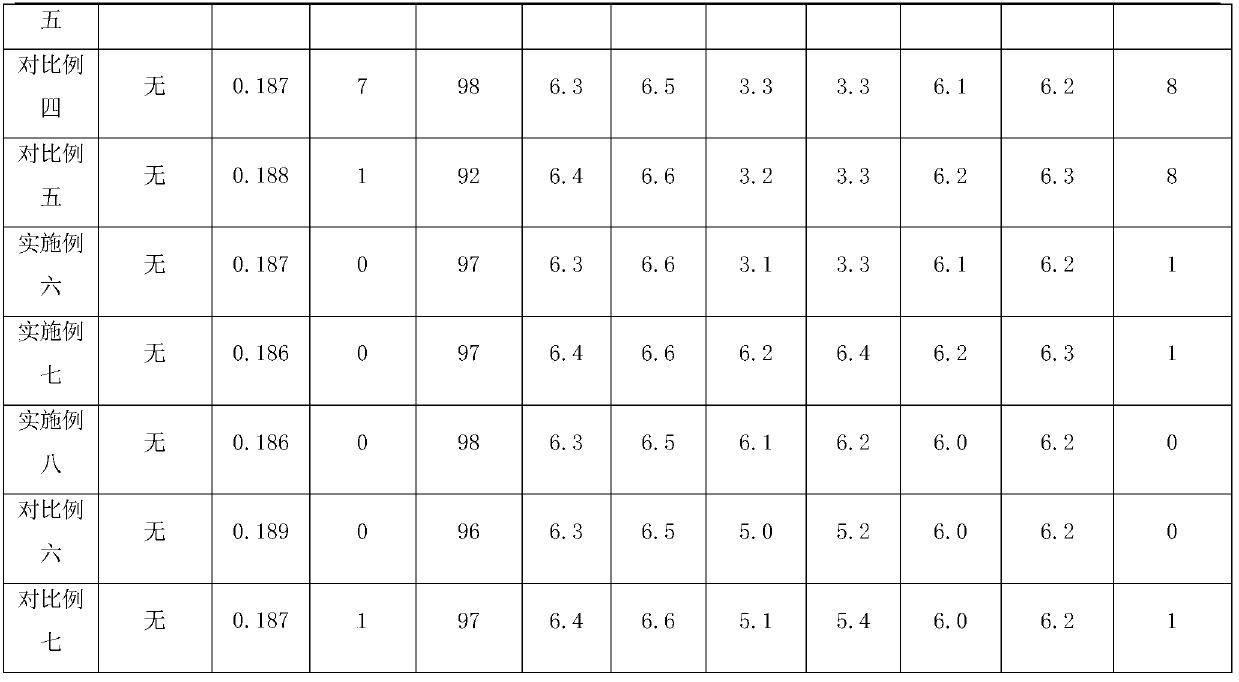

Examples

Embodiment 1

[0035] A preparation method of an environment-friendly clothing packaging film, comprising the steps of:

[0036] Step 1: take by weighing 65Kg MDPE, 7Kg erucamide, 5Kg silicon dioxide and 1Kg antioxidant as the raw materials of the intermediate layer, take by weighing 75Kg EVA, 3Kg silicon dioxide and 11Kg HDPE as the raw materials of the surface layer one and surface layer two;

[0037] Step 2: adding the raw materials of the intermediate layer, surface layer 1 and surface layer 2 prepared in step 1 into three extruders for separate melting and mixing;

[0038] Step 3: Transport the melted raw materials from the three extruders to the same blow molding die for three-layer co-extrusion, and then cool, cut, and roll to obtain the finished environmentally friendly clothing packaging film.

[0039] Wherein, the total thickness of the packaging film is 0.5mm, and the thickness ratio of the first surface layer, the middle layer and the second surface layer is 1:2:1, and the thickn...

Embodiment 2

[0041] A preparation method of an environment-friendly clothing packaging film, comprising the steps of:

[0042] Step 1: take 70Kg MDPE, 9Kg erucamide, 7Kg silicon dioxide and 2Kg antioxidant as the raw materials of the intermediate layer, weigh 80Kg EVA, 5Kg silicon dioxide and 15Kg HDPE as the raw materials of the surface layer one and surface layer two;

[0043] Step 2: adding the raw materials of the intermediate layer, surface layer 1 and surface layer 2 prepared in step 1 into three extruders for separate melting and mixing;

[0044] Step 3: Transport the melted raw materials from the three extruders to the same blow molding die for three-layer co-extrusion, and then cool, cut, and roll to obtain the finished environmentally friendly clothing packaging film.

[0045] Wherein, the vacuum inside the blow molding head is 0.01-0.02Mpa, the particle size of silicon dioxide is less than 10um, and the antioxidant is a mixture of tea polyphenols and vitamin E, and the quality o...

Embodiment 3

[0047]A preparation method of an environment-friendly clothing packaging film, comprising the steps of:

[0048] Step 1: take by weighing 75Kg MDPE, 11Kg erucamide, 9Kg silicon dioxide and 3Kg antioxidant as the raw material of the intermediate layer, take by weighing 85Kg EVA, 7Kg silicon dioxide and 19Kg HDPE as the raw material of the surface layer one and surface layer two;

[0049] Step 2: adding the raw materials of the intermediate layer, surface layer 1 and surface layer 2 prepared in step 1 into three extruders for separate melting and mixing;

[0050] Step 3: Transport the melted raw materials from the three extruders to the same blow molding die for three-layer co-extrusion, and then cool, cut, and roll to obtain the finished environmentally friendly clothing packaging film.

[0051] Wherein, the vacuum inside the blow molding head is 0.01-0.02Mpa, the particle size of silicon dioxide is less than 10um, and the antioxidant is a mixture of tea polyphenols and vitamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com