A high-precision plate-free hot stamping process

A high-precision, high-tech technology, which is applied in printing, coating, polyester coating, etc., can solve the problems of high price, impact, and limited accuracy of bronzing, and achieve the effects of high bronzing brightness, reduced production costs, and improved bronzing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

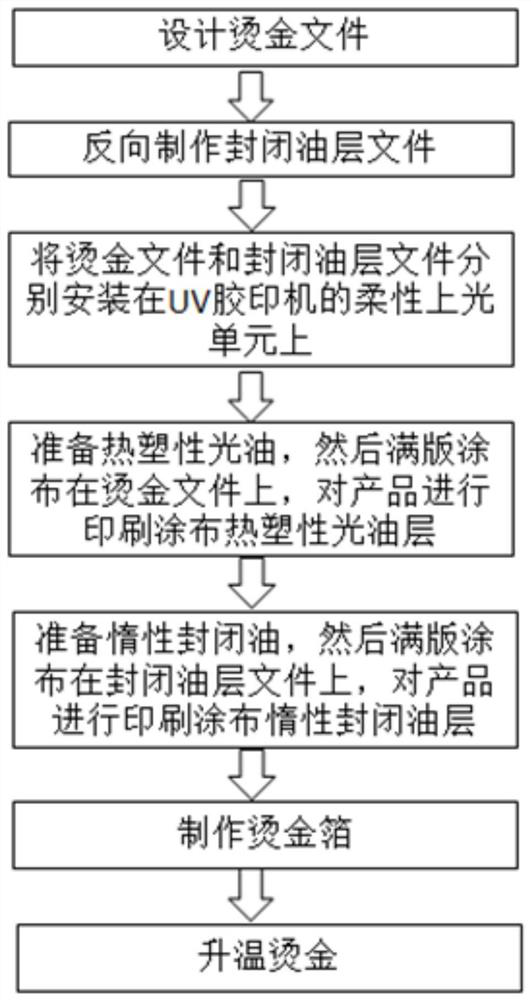

[0025] A high-precision plate-free hot stamping process, comprising the following preparation steps:

[0026] The first step is to design the stamping document according to the stamping text or pattern.

[0027] The second step is to reversely make the closed oil layer file, that is, the structure of the bronzing file and the closed oil layer file are complementary.

[0028] In the third step, the bronzing document and the closed oil layer document are respectively installed on the flexible glazing unit of the UV offset printing machine.

[0029] The fourth step is to prepare thermoplastic varnish. The main component of thermoplastic varnish is acrylic resin. Compared with the glue used in cold stamping in the prior art, the cost is only 20% of that of cold stamping glue. On the bronzing document, the thickness of the thermoplastic varnish coated on the bronzing document is 3-4um, and the product is printed and coated with a thermoplastic varnish layer.

[0030] The fifth st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com