A docking type axle box positioning device with built-in active adjustment of longitudinal displacement

A longitudinal displacement and active adjustment technology, applied in axle box installation, bogie, transportation and packaging, etc., can solve the problem of inability to actively adjust the longitudinal displacement of the wheelset and bogie frame, inability to simultaneously ensure the horizontal and vertical positioning effect, axle box. The structure of the positioning device is complex and other problems, so as to achieve the effect of good longitudinal positioning effect, simple structure and quality reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

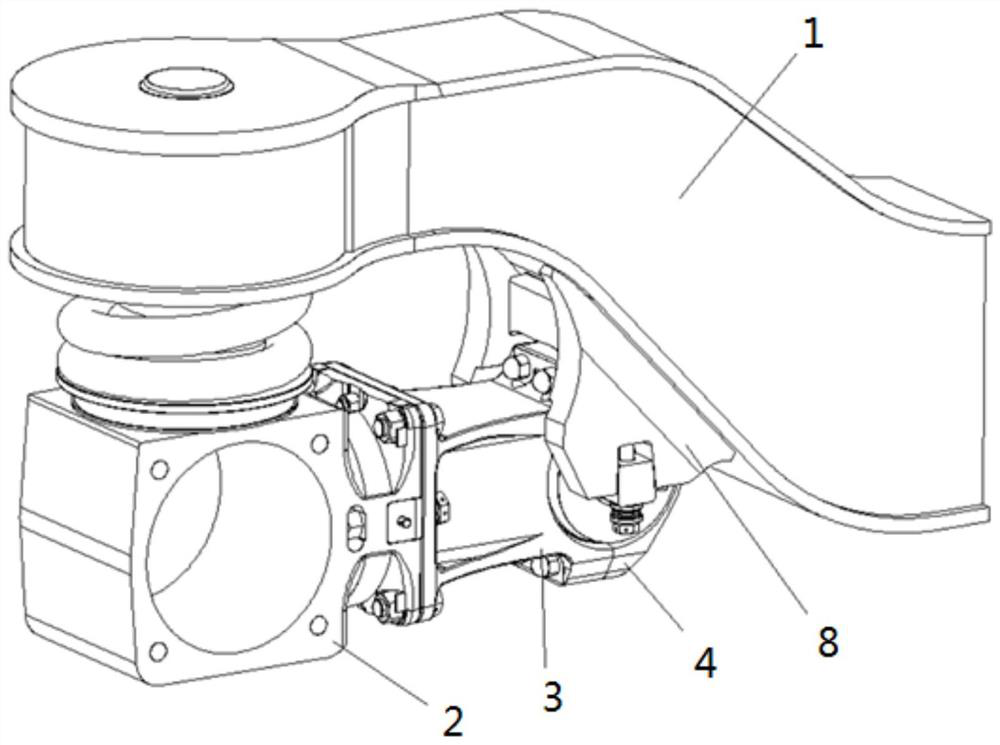

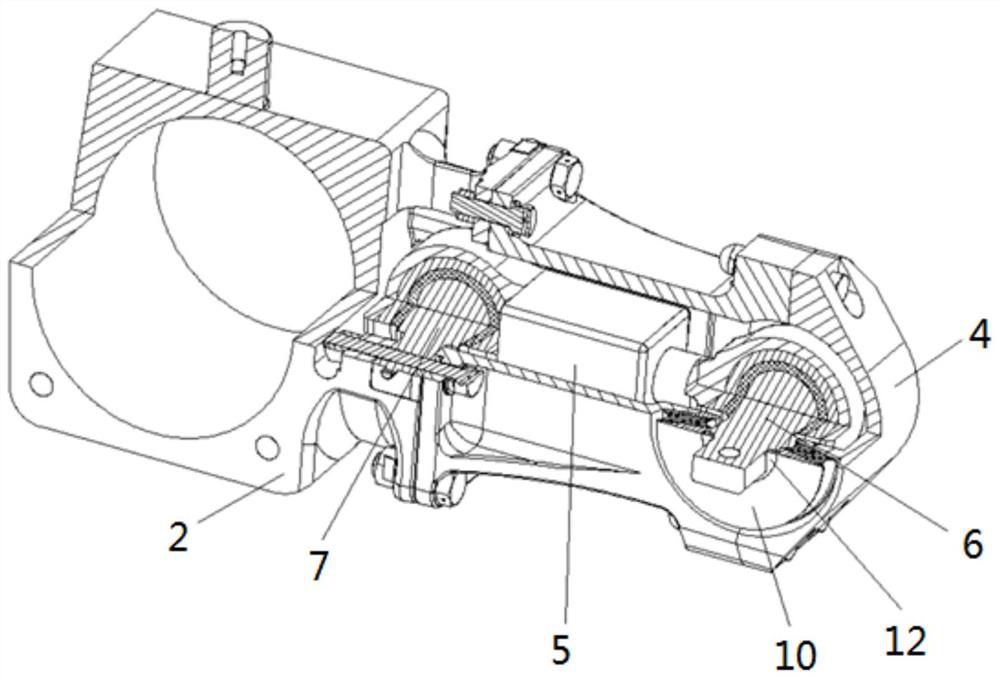

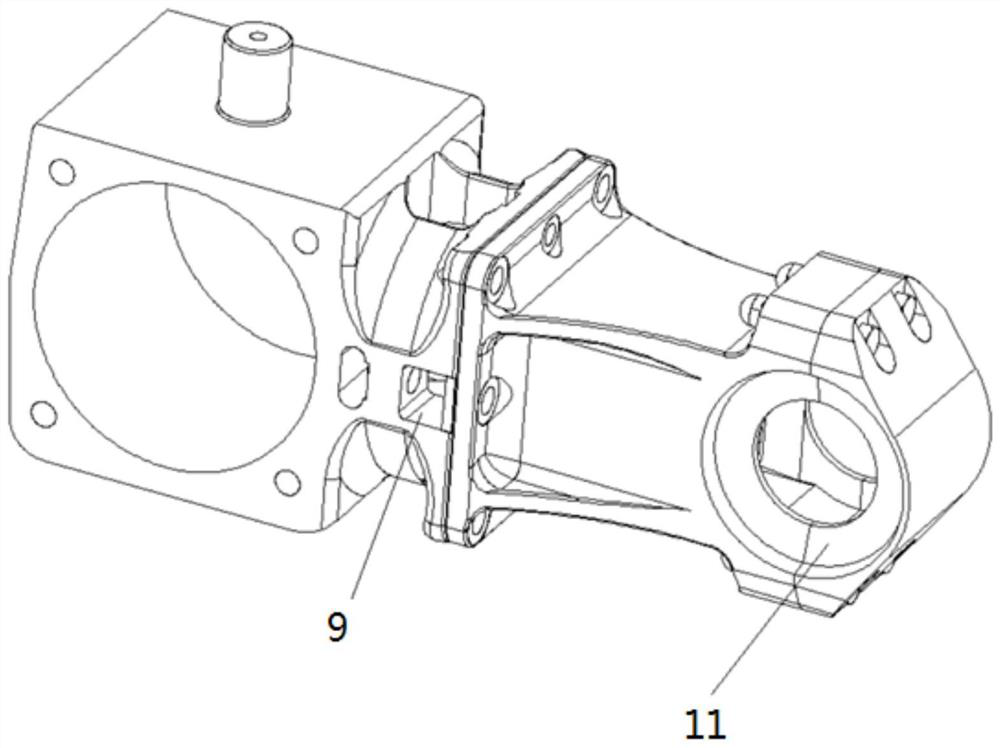

[0027] like Figure 1~3 As shown, a docking type axle box positioning device with an embedded active adjustment of longitudinal displacement is used for active adjustment of longitudinal displacement and positioning connection between the wheel set and bogie frame 1. The device includes an axle box and is placed in the axle box cavity. The longitudinal positioning unit of the actuator and the lateral positioning unit of the rubber pile, the wheel set and the bogie frame 1 are actively adjusted and positioned for longitudinal displacement and connection through the axle box, wherein the longitudinal positioning unit of the actuator is connected to the axle box and The bogie frame 1 performs longitudinal positioning, and the rubber stack lateral positioning unit connects the axle box and the bogie frame 1 for lateral positioning. The vertical positioning function and the horizontal positioning function are integrated on the axle box 2, the layout is compact, the structure is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com