Light side wall suspended vertical force transmission rack and first-stage engine

An engine and frame technology, which is applied in the field of lightweight sidewall hanging vertical force transmission frames and first-class engines, can solve the problems of large difference in engine height and size, low structural utilization efficiency, and occupying cabin space, etc. Avoid the effects of low-efficiency structure, high thrust transmission efficiency, and short force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

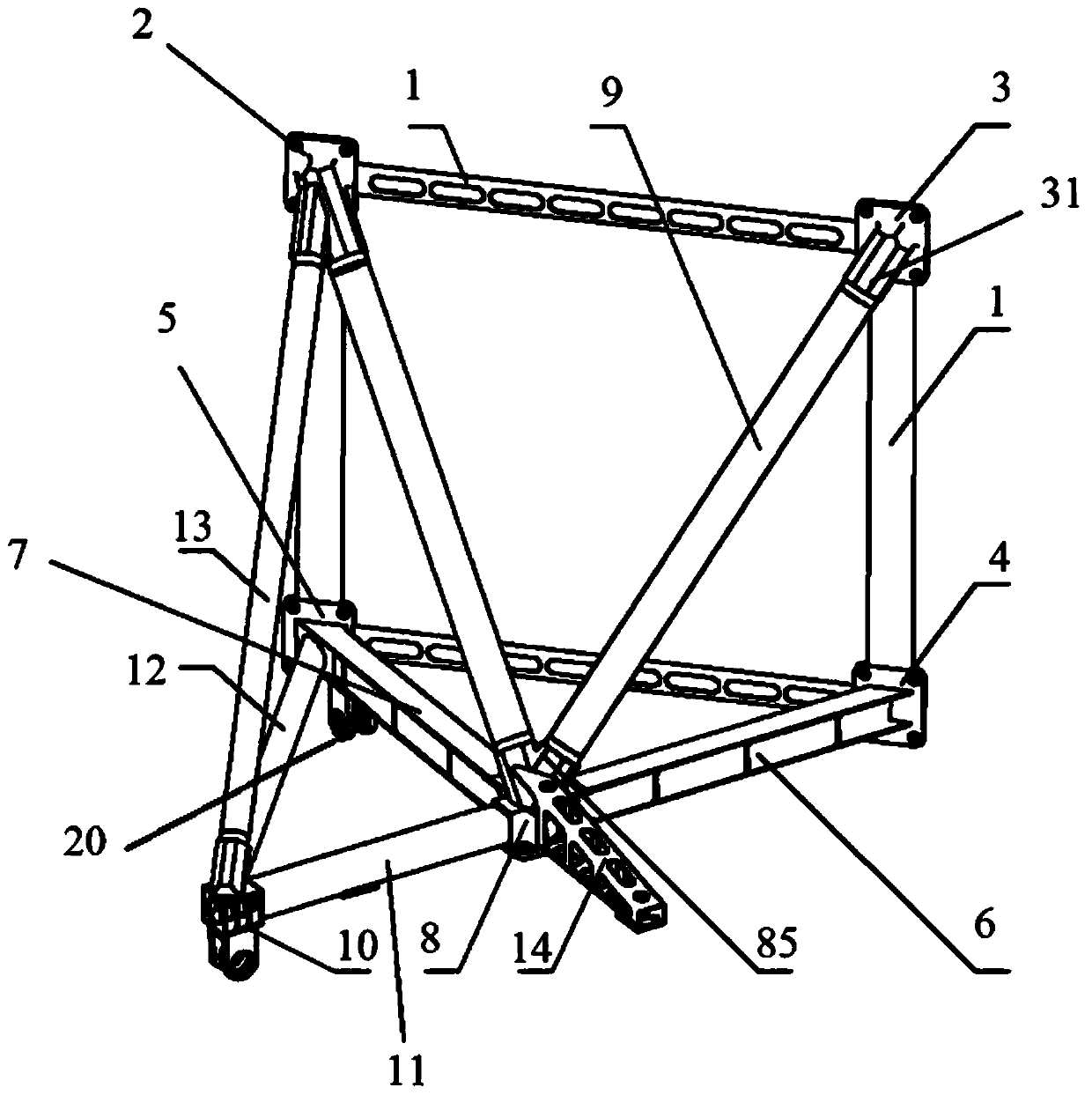

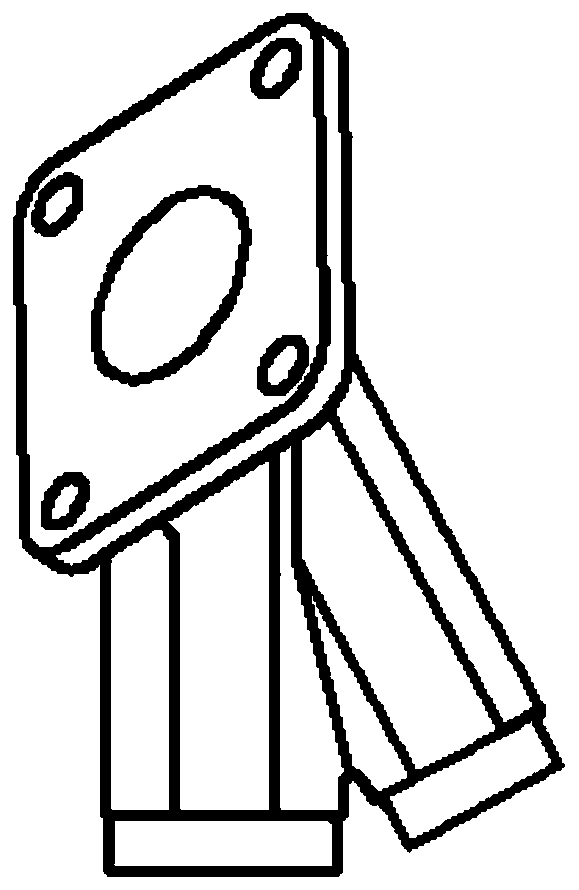

[0055] This embodiment is based on the general assembly layout of four machines, and provides a force transmission device with certain strength and rigidity, capable of withstanding a wide range of load changes, light in weight and high in efficiency, simple in structure and reliable in a limited space.

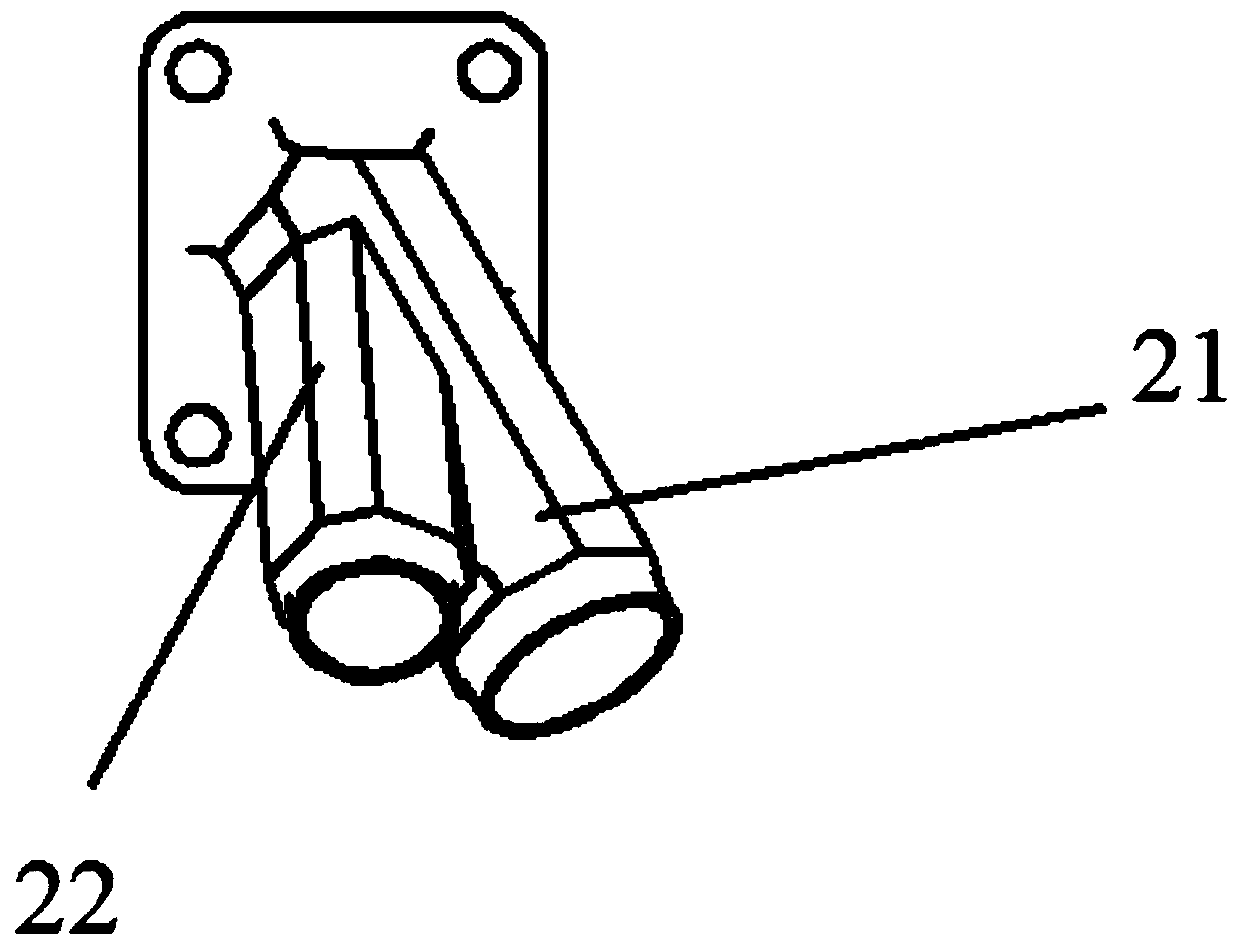

[0056] As the first-stage engine of the vertical take-off and landing reusable launch vehicle, a total of four engines with two large and two small engines are used to form a combined power. The engine installation is designed as a split frame, and the two large engines are fixed by the existing frame structure, and the two small engines with small height and thrust among the four machines are separately designed for power transmission; due to the large radial distance of the small engines, Each small engine is closer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com