Coating and slitting production line

A production line and spraying machine technology, applied in coating, spray booth, spray device and other directions, can solve the problems of reduced production efficiency, low production yield, and low improvement of diaphragm modification performance, so as to reduce waste of edge material and improve finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with specific embodiments.

[0023] The present invention proposes a diaphragm spraying slitting production line, the specific scheme is as follows:

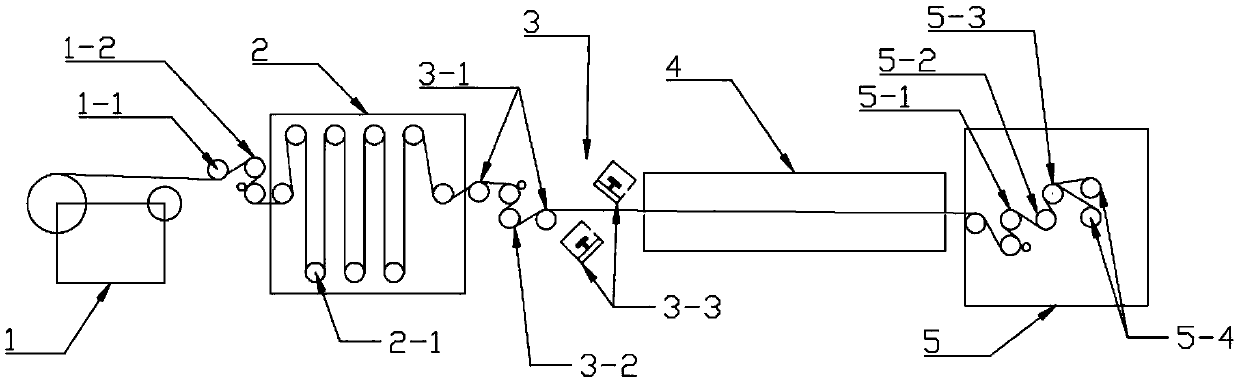

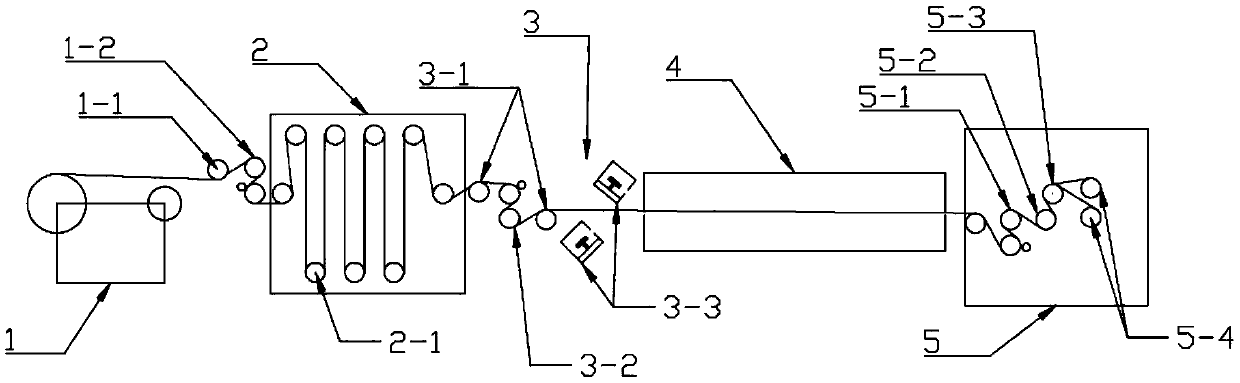

[0024] In terms of production line structure, it includes unwinding mechanism 1, diaphragm pretreatment mechanism 2, spraying mechanism 3, drying mechanism 4, and cutting mechanism 5.

[0025] 1. The unwinding mechanism 1 includes a 360° turning frame (not shown), a cutting device (not shown), a first roller (not shown), a static elimination device (not shown), and a first tension control system 1 -2. The first arc-shaped flattening roller 1-1 can change rolls automatically. Among them, the cutting device can use flying knife, sawtooth chopping knife, electric heating wire; the material of the first roller can be carbon fiber, carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com