Chemical vapor deposition device

A chemical vapor deposition and growth chamber technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as poor controllability, unfavorable process promotion, and increased productivity difficulty, to ensure stability, The effect of high growth efficiency and the most efficient growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0027] In order to achieve high reliability, low cost, and high efficiency growth of semiconductor epitaxial materials, we designed a chemical vapor deposition device, and built multiple reaction chambers in the device, and different reaction chambers grow different material structures.

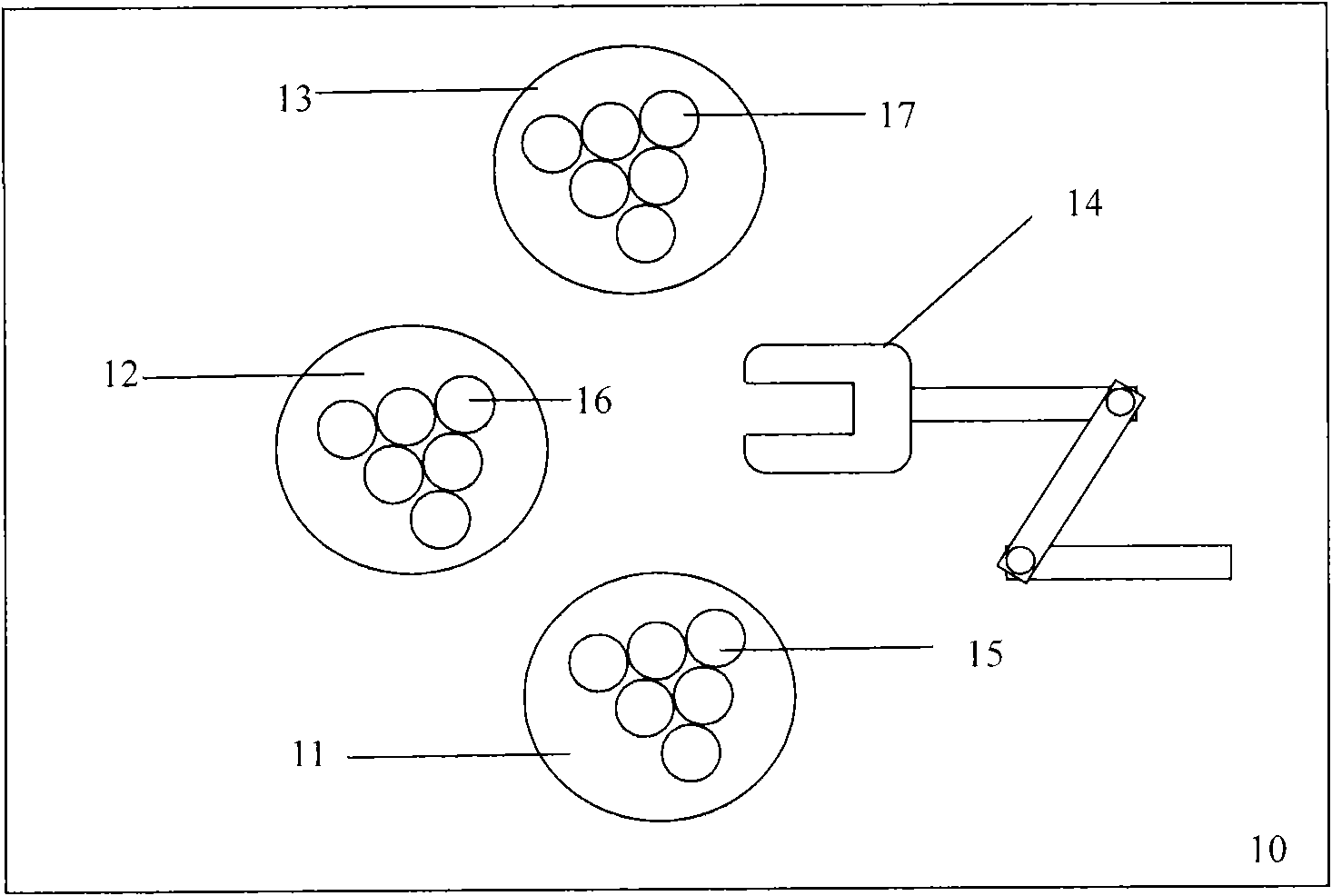

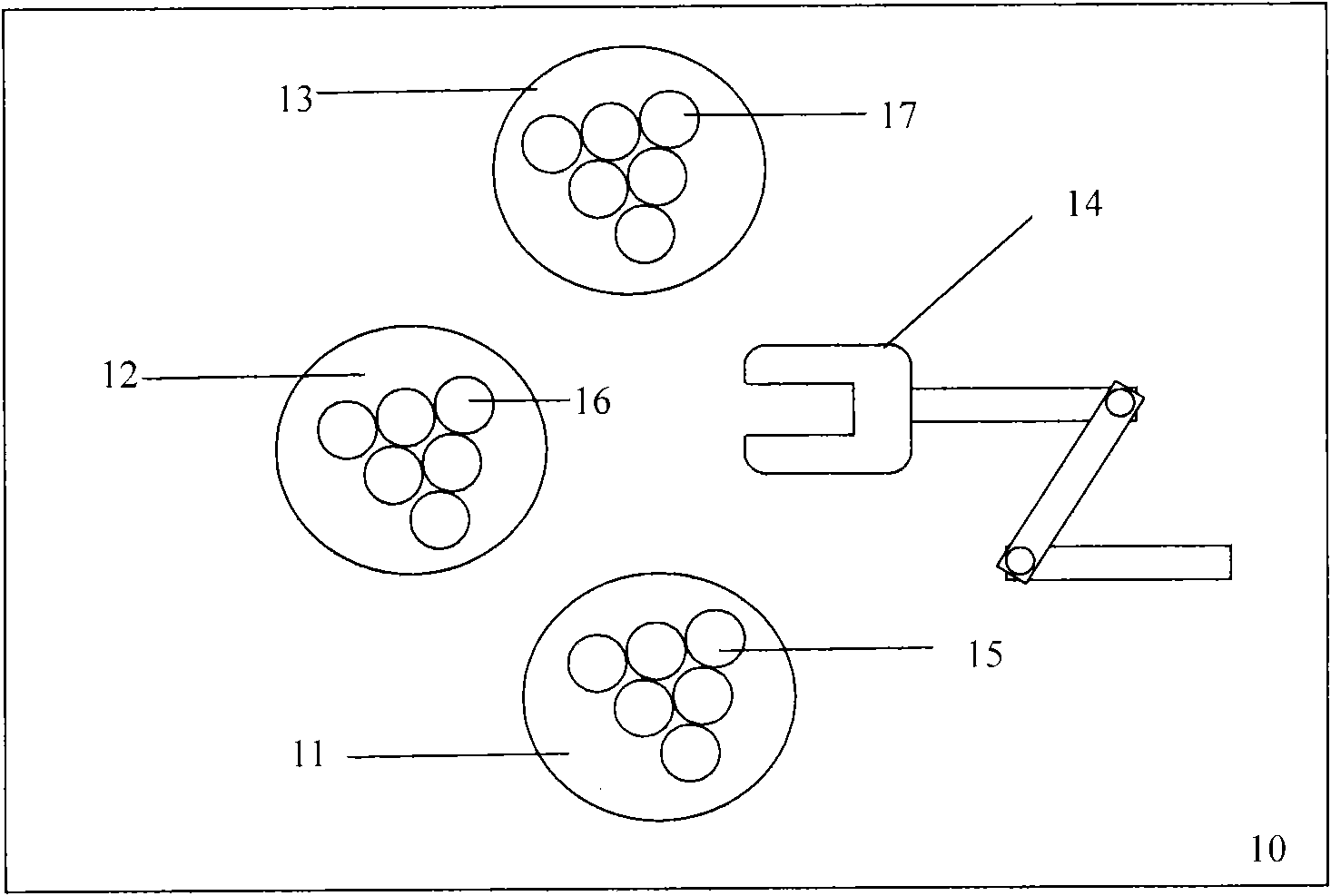

[0028] by figure 1 For example, the chemical vapor deposition device designed by the present invention includes three independent reaction chambers, wherein reaction chamber 11 is dedicated to the growth of n-type layer epitaxial material (independent n-type layer epitaxial material growth chamber), and reaction chamber 12 is dedicated to active Layer growth (independent active layer growth chamber), the reaction chamber 13 is dedicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com