Electrolytic cell suitable for pressurizing circulating pump shell and working method thereof

A technology of electrolyzer and circulation pump, applied in the field of electrolyzer, which can solve the problems of easy leakage of circulation pump and large pressure difference between inside and outside of circulation pump, and achieve the effect of optimizing structure and shortening pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

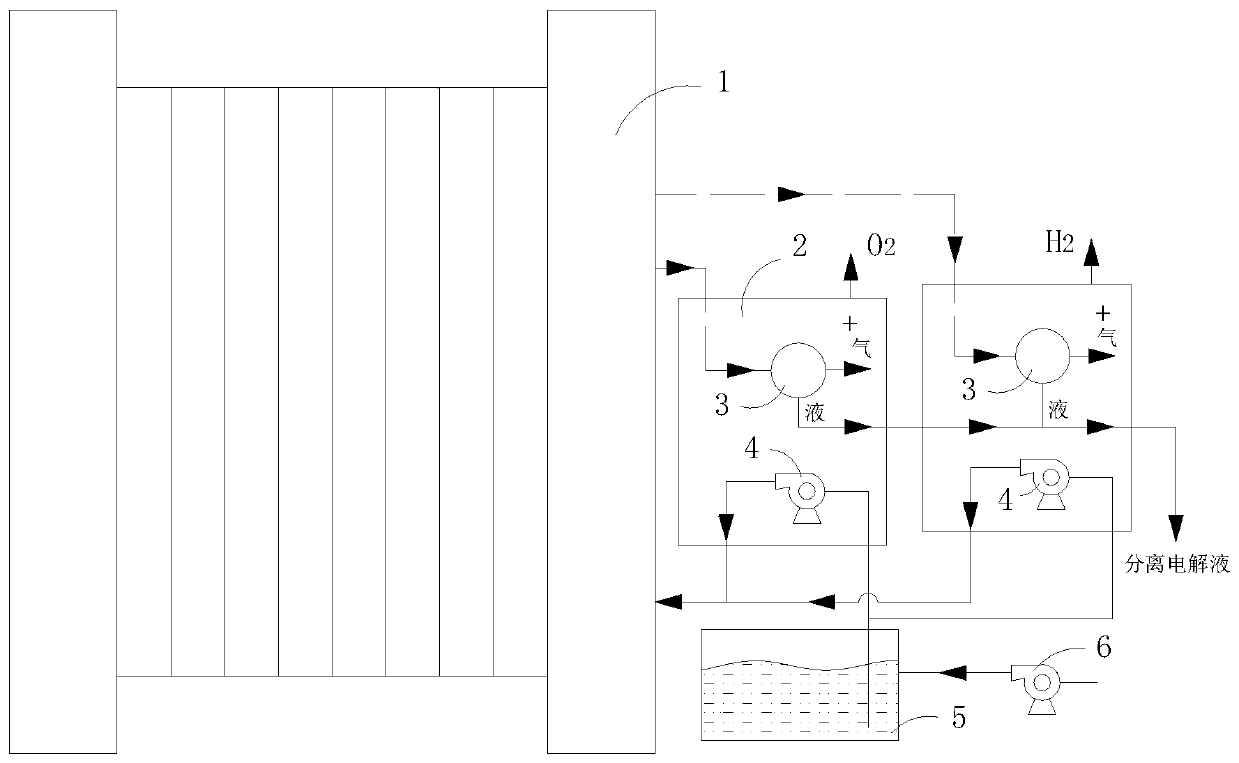

[0035] Such as figure 1 As shown, an electrolytic cell 1 suitable for pressurizing the casing of a circulating pump 4 includes at least one working chamber 2;

[0036] A gas-liquid separator 3, the gas-liquid separator 3 is in communication with the hydrogen outlet or oxygen outlet of the electrolytic cell 1, and is suitable for communicating the separated hydrogen or oxygen into the working chamber 2, so that a positive pressure (attached) is formed in the working chamber 2 "+" in the figure indicates that the cavity is under positive pressure);

[0037] The circulating pump 4 is connected with the liquid inlet of the electrolytic cell 1 and is suitable for delivering electrolyte to the electrolytic cell 1;

[0038] The circulating pump 4 is arranged in the working chamber 2 so that the casing of the circulating pump 4 bears the gas pressure in the working chamber 2 .

[0039] Preferably, the gas-liquid separator 3 is arranged in the working chamber 2 so as to optimize the ...

Embodiment 2

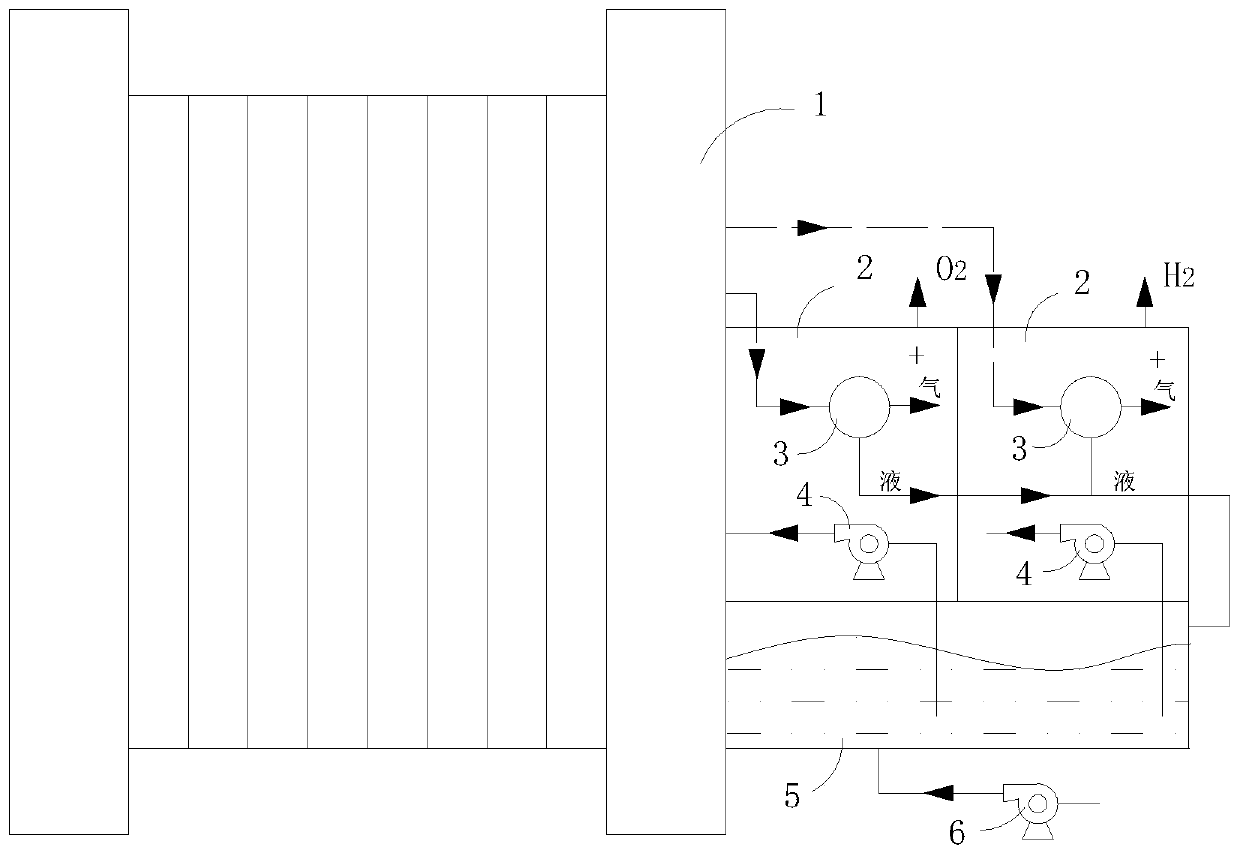

[0048] This embodiment is based on the first embodiment, and further improvements are made on the basis of the first embodiment.

[0049] Such as figure 2 As shown, an electrolytic cell 1 has two working chambers 2, which are respectively the first working chamber and the second working chamber; the gas-liquid separator 3 in the first working chamber communicates with the hydrogen outlet of the electrolytic cell 1 ; It is suitable for inputting the separated hydrogen gas into the first working chamber, so that a positive pressure is formed in the first working chamber ("+" in the drawings indicates that the chamber is under positive pressure);

[0050] The gas-liquid separator 3 in the second working chamber communicates with the oxygen outlet of the electrolytic cell 1, and is suitable for inputting separated oxygen into the second working chamber so that a positive pressure is formed in the second working chamber (" +" indicates that the chamber is under positive pressure)...

Embodiment 3

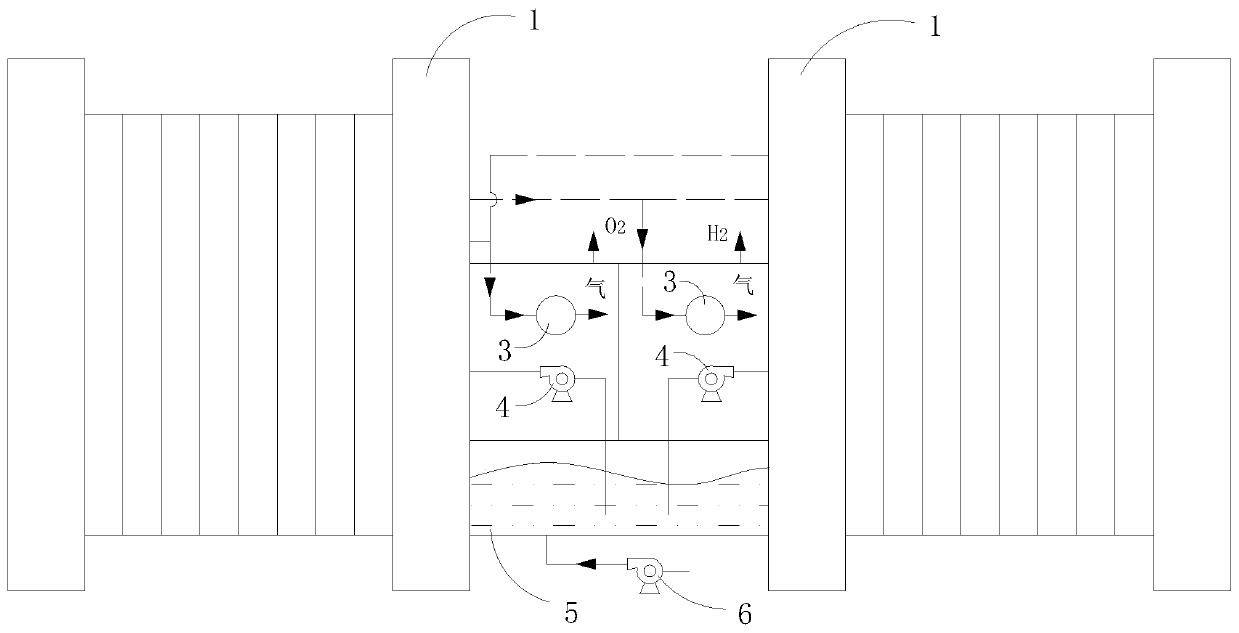

[0055] A working method for an electrolyzer, comprising the following steps:

[0056] Step S1, setting the circulating pump 4 and the gas-liquid separator 3 in the same working chamber 2;

[0057] Step S2, the gas-liquid separator 3 separates the gas output from the electrolytic cell 1, and the separated gas is input into the working chamber 2, so that a positive pressure is formed in the working chamber 2 ("+" in the drawings indicates that the chamber is under positive pressure);

[0058] Step S2, the circulating pump 4 delivers the electrolyte to the electrolytic cell 1 under the positive pressure environment.

[0059] The circulation pump 4 works in the working chamber 2 under positive pressure, which reduces the pressure difference between the inside and outside of the circulation pump 4, thereby reducing the chance of leakage of the circulation pump 4, and placing the circulation pump 4 in such a positive pressure environment for operation can Select the circulating pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com