Horizontal cement paste spraying device, paver with same and application thereof

A technology of spraying device and cement slurry, which is applied in the field of horizontal cement slurry spraying device and paver, and can solve the problem of inability to synchronize the paving work of the spraying device and the paver, poor adhesion, inconvenient upper and lower road grooves, etc. problems, to avoid cement slurry agglomeration and solidification, to ensure adhesion, and to eliminate the effect of time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

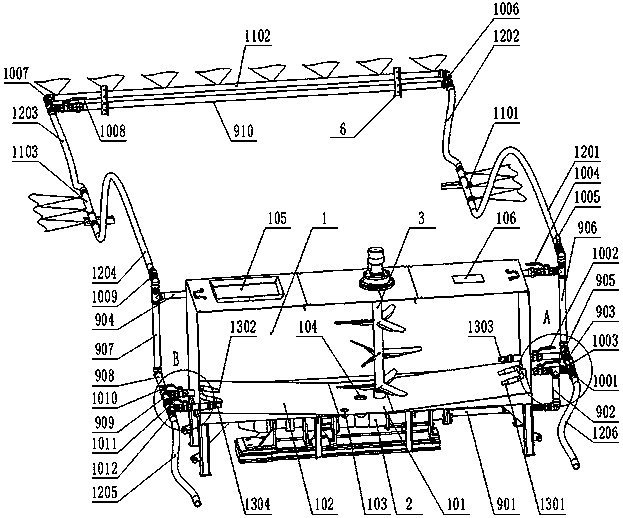

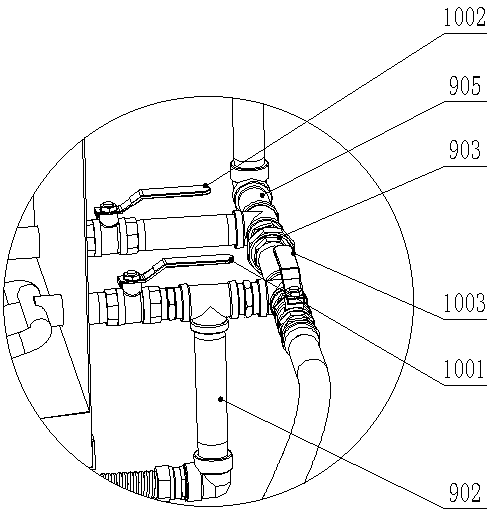

[0062] refer to figure 1 , figure 2 and image 3 , the first embodiment of the present invention relates to a horizontal cement slurry spraying device, comprising a cement tank 1 and a screw pump 2 arranged up and down, the cement tank 1 has a built-in agitator 3, and the bottom of the cement tank 1 is provided with a through-hole 104, the through-hole 104 is in sealing communication with the suction port of the screw pump 2, and the discharge port of the screw pump 2 is sequentially connected in series with the No. 1 pipeline 901, the No. 2 pipeline 902, the No. 3 pipeline 903, the No. 5 pipeline 905, the No. 1201, the first spray pipe 1101, the second hose 1202, the second spray pipe 1102, the third hose 1203, the third spray pipe 1103, the fourth hose 1204, the seventh pipe 907, the eighth pipe 908, the ninth pipe Pipeline 909 and No. 5 water discharge hose 1205;

[0063] No. 2 pipeline 902 and No. 3 pipeline 903 are connected through a three-way valve, and No. 1 valve ...

no. 2 approach

[0079] Different from the first embodiment, referring to figure 1 or Figure 4 or Figure 5 or Figure 6 In this embodiment, two return pipes are added. Specifically, No. 3 pipeline 903 and No. 5 pipeline 905 are connected through a three-way valve, and No. Ⅱ valve 1002 is installed at the third outlet of the 3-way valve. The third return pipe 1303 in the box 1 communicates;

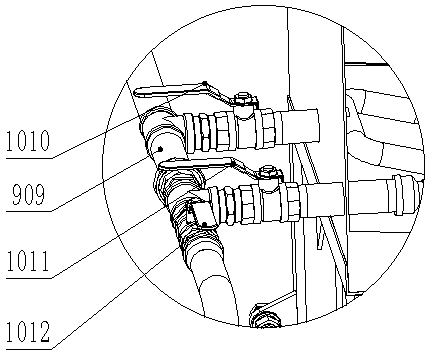

[0080] No. 9 pipeline 909 and No. 5 water discharge hose 1205 are connected by a three-way valve, and the third outlet of the three-way valve is installed with No. Ⅺ valve 1011, and No. Ⅺ valve 1011 is communicated with the fourth return pipe 1304 in the cement tank 1.

[0081] The working principle of the cement slurry spraying device of the present embodiment is as follows:

[0082] Non-spraying state: such as Figure 4 As shown, add cement to the cement tank 1 through the feeding window 105, and at the same time add clean water to the cement tank 1 through the water adding window 106, and close t...

no. 3 approach

[0088] On the basis of the second embodiment, refer to figure 1 or Figure 4 or Figure 5 or Figure 6 , the third return pipe 1303 and the fourth return pipe 1304 have the same structure and are oppositely arranged. They are both straight pipes. One end of the straight pipe communicates with No. II valve 1002 or No. XI valve 1011, and the other end runs through the cement tank 1. The box wall extends into the cement box 1 and is close to the bottom of the cement box 1.

[0089] In order to enhance the flushing pressure, the first return pipe 1301 and the second return pipe 1302 have the same structure and are arranged opposite to each other. They are both composed of a U-shaped pipe and a straight pipe. At the bottom of the cement box 1, the sealing end opposite to the open end communicates with the straight pipe, and the straight pipe runs through the wall of the cement box 1 to connect with No. I valve 1001 or connect with No. X valve 1010.

[0090] refer to figure 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com