Anti-water-accumulation foaming floor

A technology for preventing stagnant water and flooring, which is applied in grinding machines, construction, grinding/polishing equipment, etc. It can solve the problems of large overall floor quality, many materials used, and bulky costs, and achieve weight reduction, light weight, high strength, and high performance. The effect of rich techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

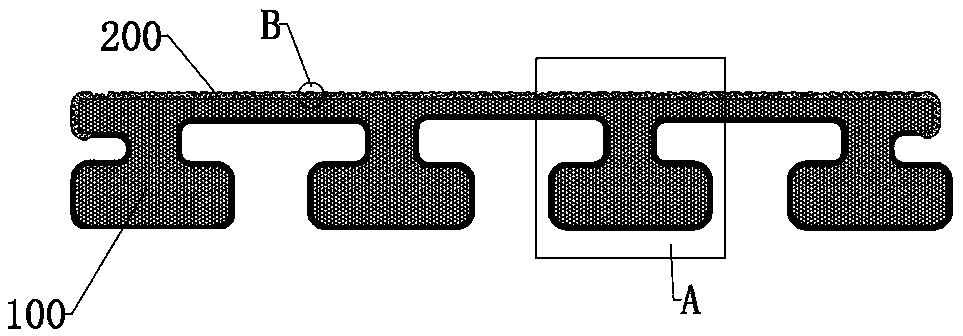

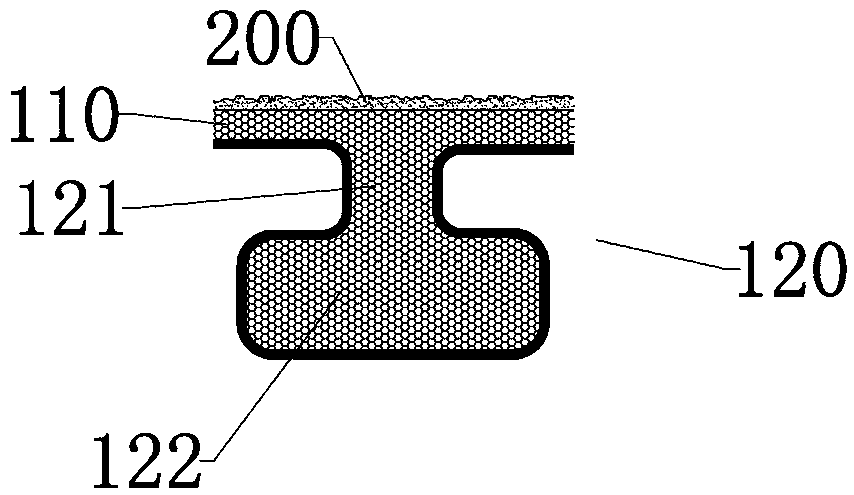

[0044] Such as figure 1 As shown, a waterlogging-resistant foam floor includes a foam base 100 formed of resin and having a block structure, and a hard surface layer 200 integrally connected with the foam base and covering the foam base 100 . The foam base 100 is integrally connected by a surface plate 110 and a plurality of supporting units 120 . The foam base 100 is made of PVC foam material, and the hard surface layer 200 is made of ASA non-foam material.

[0045] Such as figure 2 As shown, each support unit includes a support plate 121 and a pressure bottom plate 122 integrally connected, the support plate 121 is arranged vertically, and the pressure bottom plate 122 is arranged horizontally.

[0046] Such as figure 1 As shown, a vacant area 130 is formed between adjacent supporting units 120, so that the lower bottom surface of the floor is discontinuous.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com