Drilling tool, pile forming device and pile forming construction method for displacement pile

A drilling tool and piling technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of inconvenient upper-spin and pull-out of the helical blades, and achieve the effect of easy drilling up and down drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

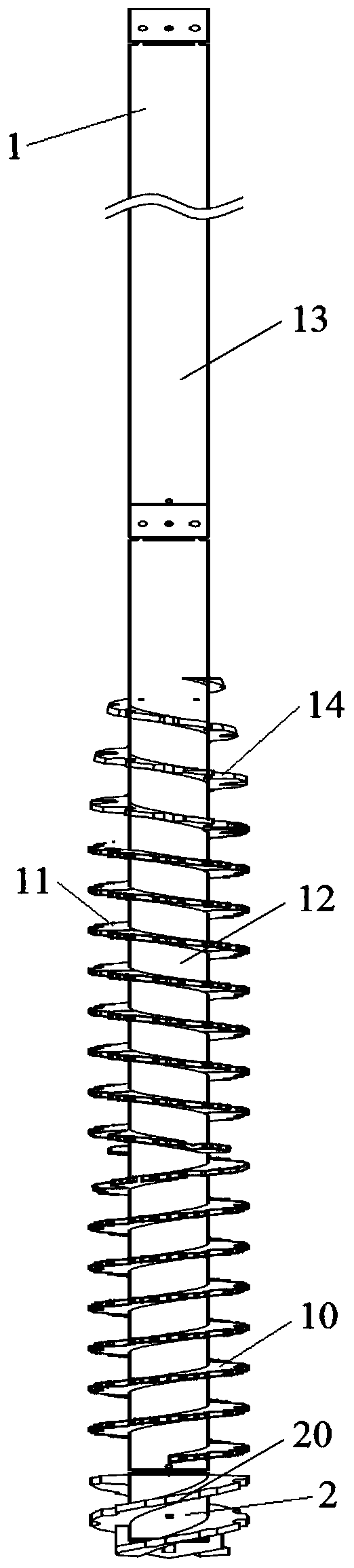

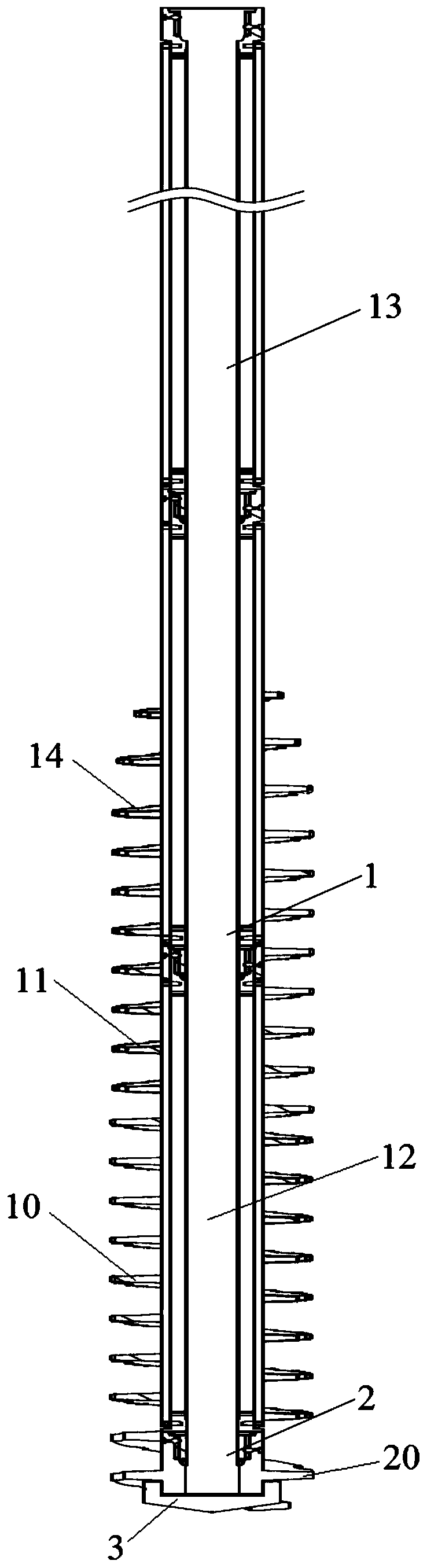

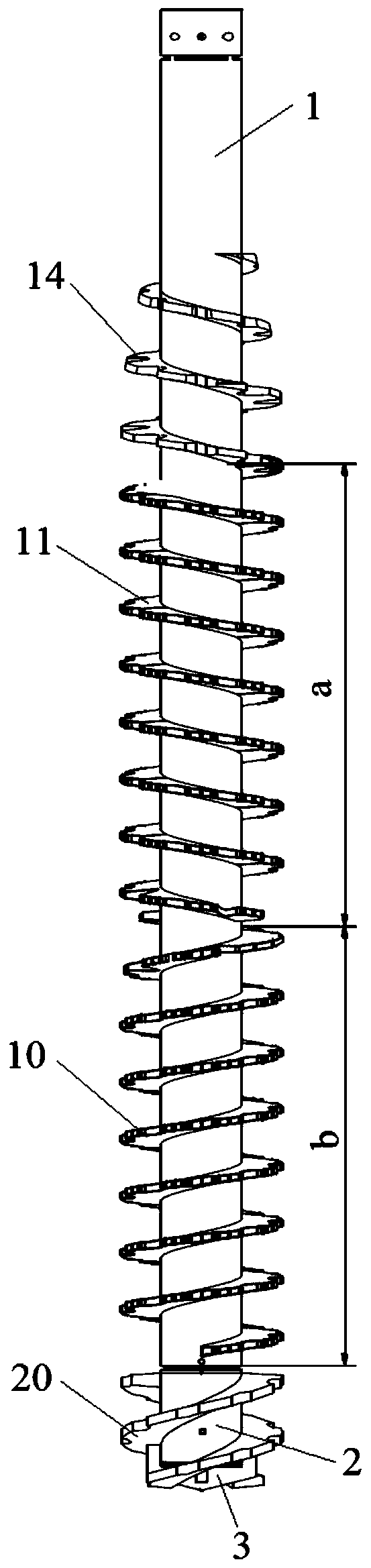

[0046] Such as Figure 1-Figure 5 As shown, the drilling tool provided by this embodiment includes a cylindrical drill rod 1, and the drill rod 1 includes a front end and a rear end. Along the length direction of the drill rod 1, two sections on the drill rod 1 are respectively provided with a forward helical blade 10 and a reverse helical blade 11, and the forward helical blade 10 is arranged on the side near the front end of the drill rod 1, The reverse helical blade 11 is arranged between the forward helical blade 10 and the rear end of the drill rod 1 . Both the forward helical blade 10 and the reverse helical blade 11 surround the outer peripheral wall of the drill pipe 1 and extend along the length direction of the drill pipe 1, and the direction of rotation of the forward helical blade 10 is the same as that of the reverse helical blade 11. on the contrary.

[0047] The forward direction in this embodiment refers to the direction in which the helical blade rotates and...

Embodiment 2

[0084] Such as Figure 6-Figure 8 As shown, the drilling tool provided in this embodiment and the drilling tool in the first embodiment also include a hollow cylindrical drill rod 1. Along the length direction of the drill rod 1, forward helical blades 10 are sequentially arranged on the body of the drill rod 1. And reverse helical blade 11. Both the forward helical blade 10 and the reverse helical blade 11 surround the outer peripheral wall of the drill pipe 1 and extend along the length direction of the drill pipe 1, and the direction of rotation of the forward helical blade 10 is the same as that of the reverse helical blade 11. on the contrary.

[0085] Such as Figure 6-Figure 8 As shown, the other features of the drilling tool provided by this embodiment are the same as those of the drilling tool in Embodiment 1, and will not be repeated here. The difference between the drilling tool provided in this embodiment and the first embodiment is that the forward helical blad...

Embodiment 3

[0091] The piling device provided in this embodiment includes a concrete conveying mechanism, a first driving mechanism, a second driving mechanism, and also includes the drilling tool in the first embodiment or the drilling tool in the second embodiment. The concrete conveying mechanism and the drill pipe in the drilling tool are communicated through pipelines. Both the first drive mechanism and the second drive mechanism are connected with the drill rod, the first drive mechanism is used to drive the drill rod to rotate, and the second drive mechanism is used to drive the drill rod to approach or move away from the ground.

[0092] The concrete conveying mechanism can be an existing concrete conveying pump, the first driving mechanism can be a motor, the second driving mechanism can be a hydraulic cylinder, and the first driving mechanism and the second driving mechanism can also adopt the existing soil-squeezing pile construction process The power system used in.

[0093] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com