Transport device for cutting hole support in coal mining laneway and use method thereof

A transportation device and eye-cutting technology, which is applied in transportation and packaging, underground transportation, earth drilling and mining, etc., can solve the problems of coal mine production efficiency reduction, bracket damage, safety hazards, etc., and avoid manual operation signal transmission not in time , Improve production efficiency and economic benefits, and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

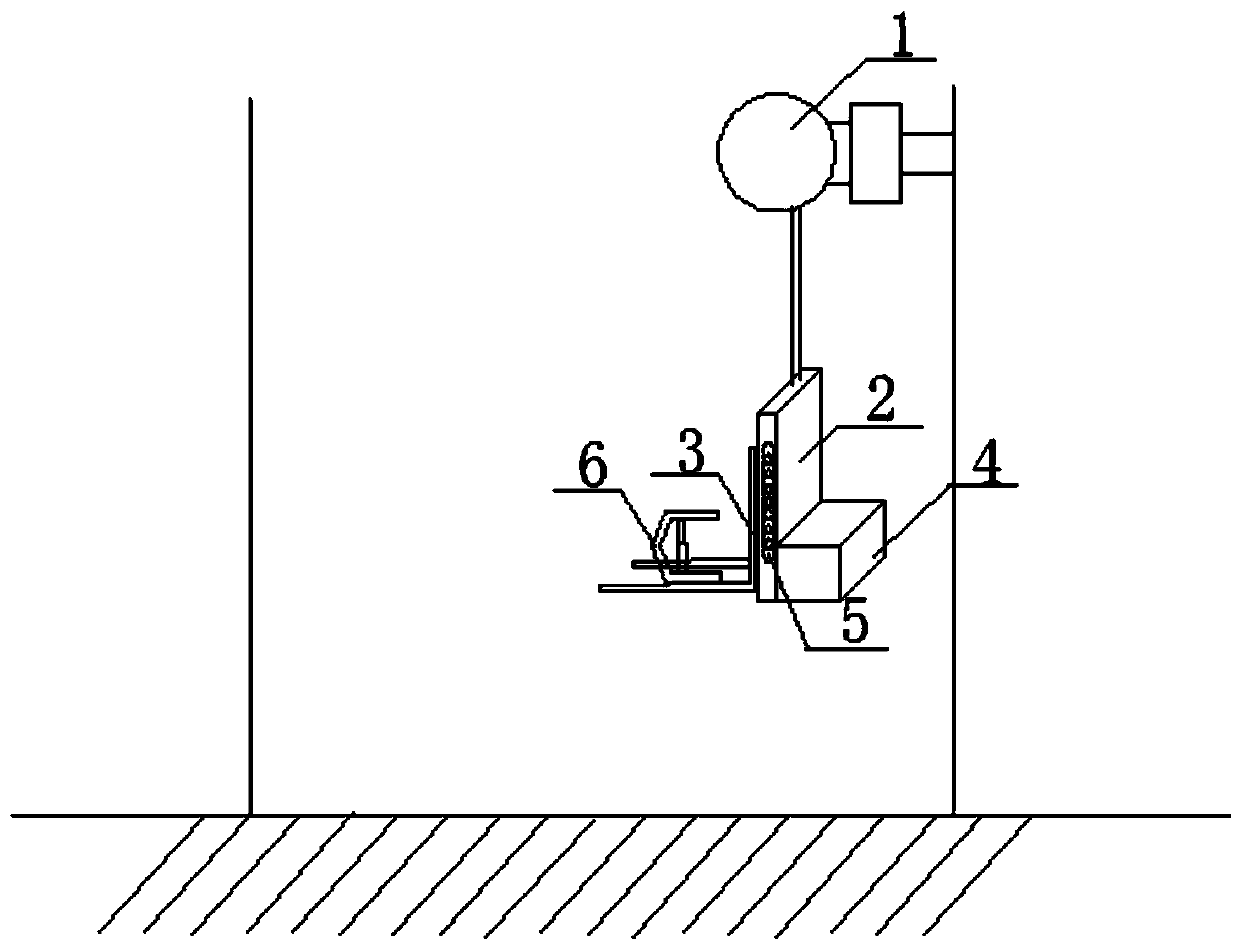

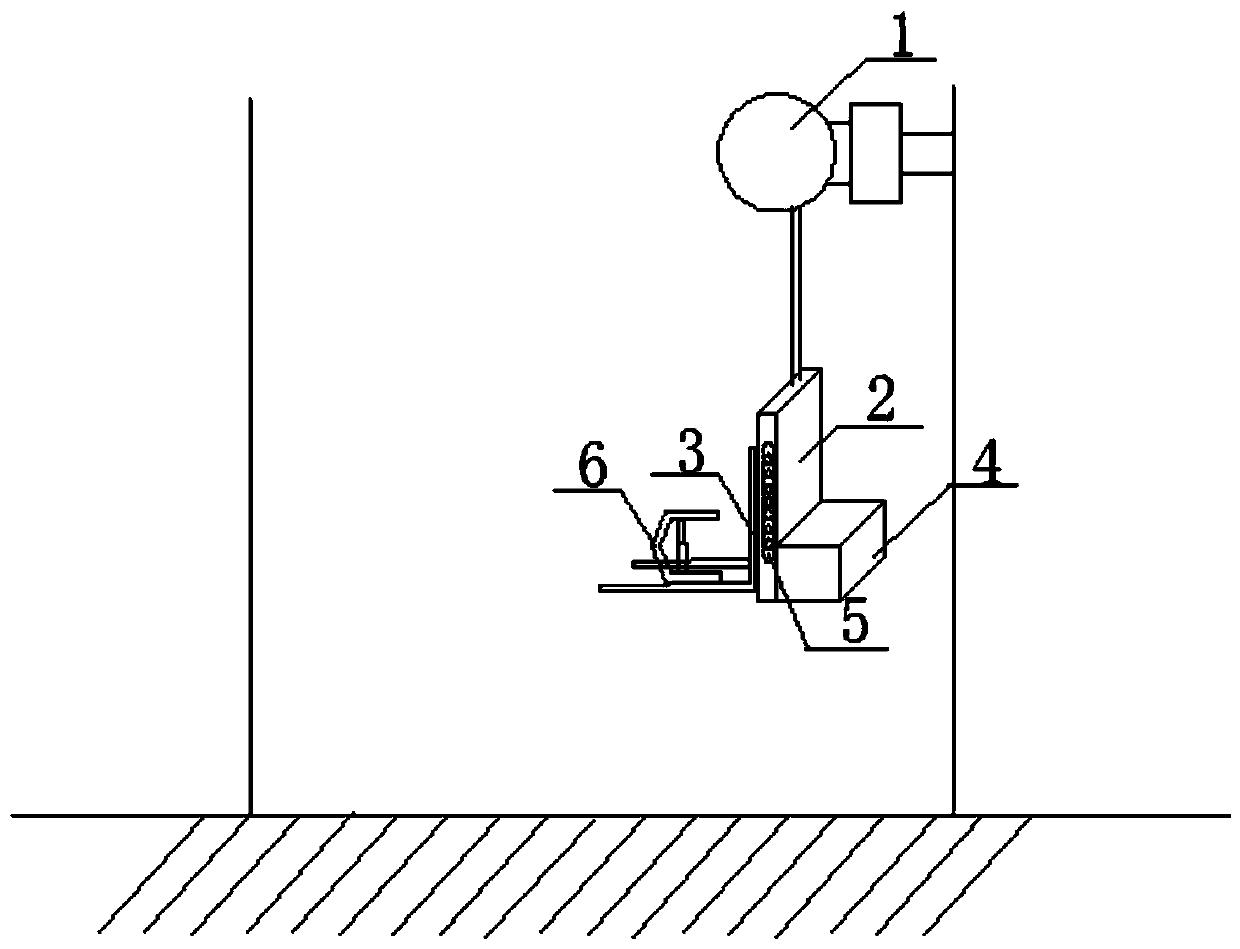

[0021] figure 1 It is a schematic diagram of the structure of a transportation device used for cut-off support of coal mining roadways according to the present invention, as shown in the figure:

[0022] The present invention discloses a transportation device for supporting the cut hole of a coal mining roadway. It includes a hoist 1 placed at the entrance of the large side cut hole of the roadway brush. The chain drive of the hoist 1 is loaded with an installation forklift used to support the roof support of the roadway. 2. The installation forklift 2 is also provided with a fixed bracket chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com