Single-hole type heat exchanger

A technology for heat exchangers and heat exchange cores, applied in the directions of heat exchanger sealing devices, heat exchange equipment, heat exchanger shells, etc., can solve the problems of low installation efficiency, poor waterproofness, and low heat exchange efficiency of heat exchangers, etc. Achieve the effect of improving sealing, improving heat exchange efficiency, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

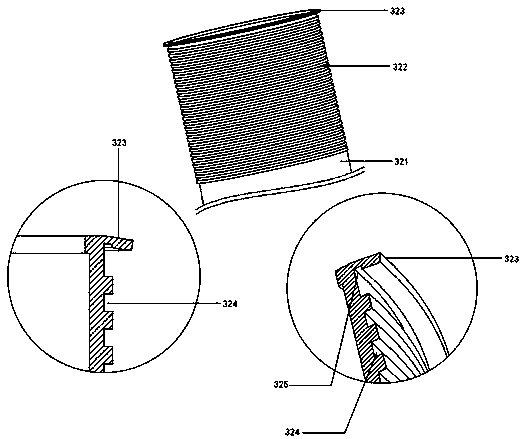

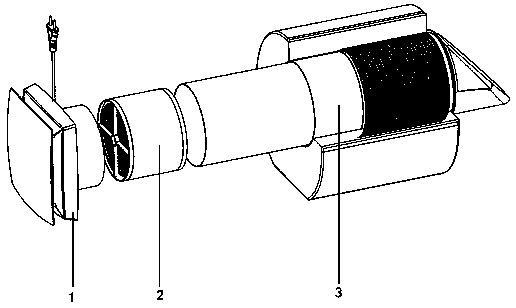

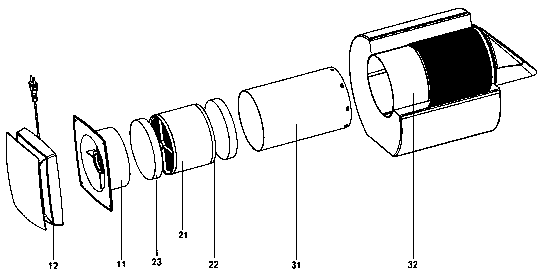

[0029] refer to Figure 1-3 As shown, a single-hole heat exchanger using a foam heat exchange core includes an exhaust fan assembly 1, a heat exchange core assembly 2 connected to the exhaust fan assembly 1, and a heat exchange core assembly 2 Connected wall exhaust pipe assembly 3, the exhaust fan assembly 1 includes a motor bracket exhaust pipe 11, and an exhaust fan front cover 12 installed on the front of the motor bracket exhaust pipe 11, the heat exchange core The assembly 2 includes a heat exchange core 21, a fixed support 22 arranged at the rear of the heat exchange core 21, and a primary filter 23 arranged at the front of the heat exchange core 21 and the rear of the fixed support 22. The wall-through exhaust pipe assembly 3 includes a heat exchange core exhaust pipe 31, and a waterproof silicone sleeve 32 that is inserted outside the heat exchange core exhaust pipe 31 and installed in the wall. The assembly 2 and the exhaust pipe 11 of the motor bracket are loaded i...

Embodiment 2

[0034] refer to Figure 1-3 As shown, a single-hole heat exchanger using a ceramic integrated heat exchange core includes an exhaust fan assembly 1, a heat exchange core assembly 2 connected to the exhaust fan assembly 1, and a heat exchange core assembly 2 connected to the heat exchange core The through-wall exhaust pipe assembly 3 connected to the assembly 2, the exhaust fan assembly 1 includes a motor bracket exhaust pipe 11, and an exhaust fan front cover 12 installed on the front of the motor bracket exhaust pipe 11, the heat The exchange core assembly 2 includes a heat exchange core 21, a fixed support 22 arranged at the rear of the heat exchange core 21, and a primary filter 23 arranged at the front of the heat exchange core 21 and the rear of the fixed support 22, The wall-through exhaust pipe assembly 3 includes a heat exchange core exhaust pipe 31, and a waterproof silicone sleeve 32 inserted outside the heat exchange core exhaust pipe 31 and installed in the wall. ...

Embodiment 3

[0039] refer to Figure 1-3 As shown, a single-hole heat exchanger using a ceramic split heat exchange core includes an exhaust fan assembly 1, a heat exchange core assembly 2 connected to the exhaust fan assembly 1, and a heat exchange core assembly 2 connected to the heat exchange core The through-wall exhaust pipe assembly 3 connected to the assembly 2, the exhaust fan assembly 1 includes a motor bracket exhaust pipe 11, and an exhaust fan front cover 12 installed on the front of the motor bracket exhaust pipe 11, the heat The exchange core assembly 2 includes a heat exchange core 21, a fixed support 22 arranged at the rear of the heat exchange core 21, and a primary filter 23 arranged at the front of the heat exchange core 21 and the rear of the fixed support 22, The wall-through exhaust pipe assembly 3 includes a heat exchange core exhaust pipe 31, and a waterproof silicone sleeve 32 inserted outside the heat exchange core exhaust pipe 31 and installed in the wall. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com