A device for drying edge banding

An edge banding and drying technology, which is applied in the direction of drying gas arrangement, progressive dryer, drying solid materials, etc., can solve the problem of reducing the processing cost of flat edge banding, affecting the processing effect of flat edge banding, and affecting the flat sealing effect. The quality of side strip products and other issues can be achieved, and the effect of good practical effect, improved drying effect and reduced drying cost can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The structural proportions in the drawings of the present invention are schematic, and the structural proportions can be determined according to actual needs.

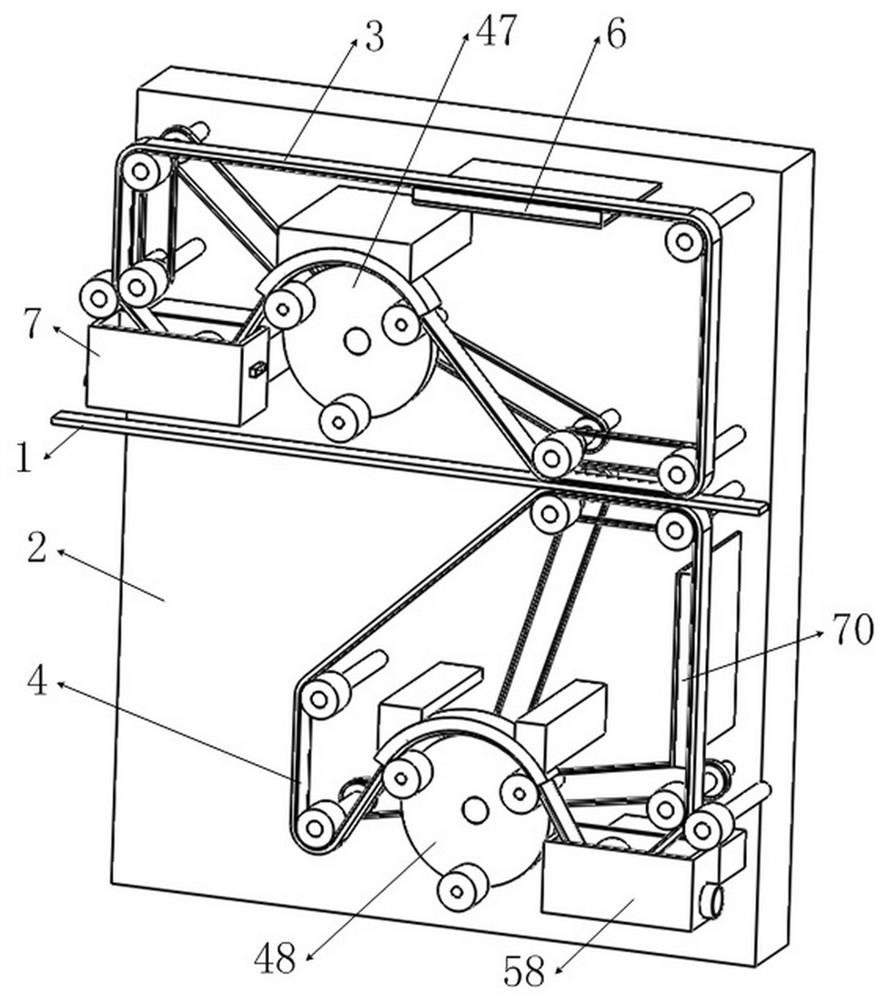

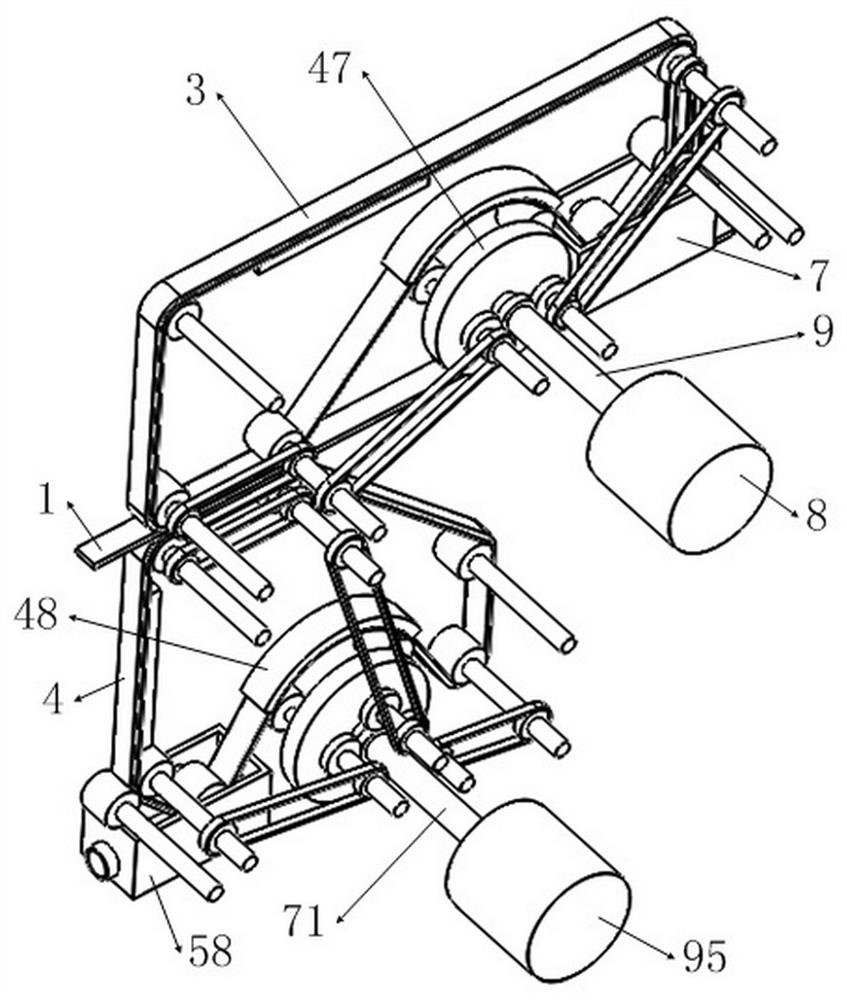

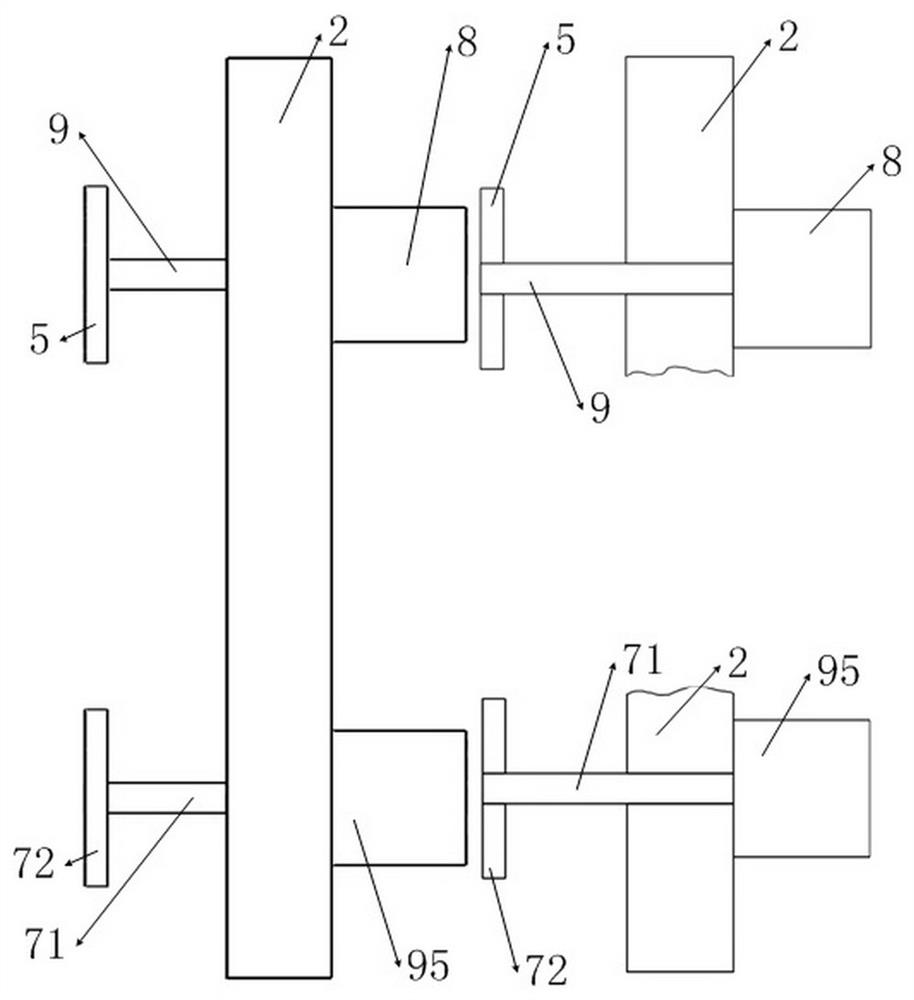

[0062] Such as figure 1 , 2 As shown, a device for drying edge banding 1, which includes A water removal mechanism 3 and B water removal mechanism 4 distributed up and down on the side of support frame 2; A water removal mechanism 3 and B water removal mechanism 4 are all on the edge banding 1 Dehydration and drying treatment.

[0063] The above-mentioned A water removal mechanism 3 includes the A heater 6 installed on the support frame 2, the A pressure roller 22, the A pushing unit 47, the A box 7 with the A nozzle 44 sealed on one side, and the A sponge is pasted on the outer surface A conveyor belt 41 with belt 42, such as figure 2 , 9 As shown, wherein the A conveyor belt 41 is arranged circularly through each roller, and the A conveyor belt 41 is driven by the rollers to transmit; as Figure 9 , 11 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com