Pressure reduction stroke measuring device for oil outlet valve

A technology for measuring devices and oil delivery valves, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of not being able to control the process quality in a timely manner, insufficient inspection accuracy, poor batch adaptability, etc., and achieve simple structure and manufacturing The effect of low cost and precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

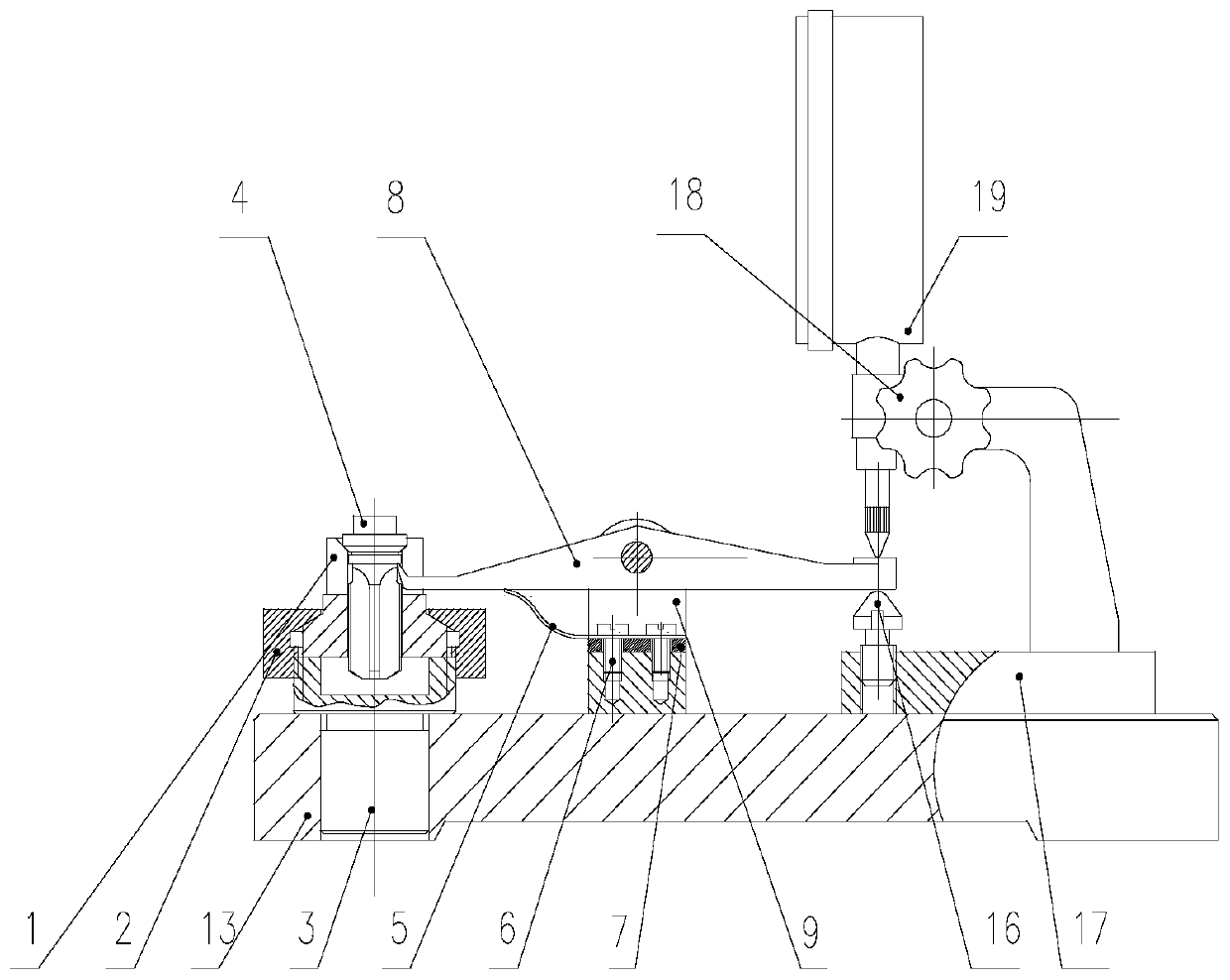

[0029] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

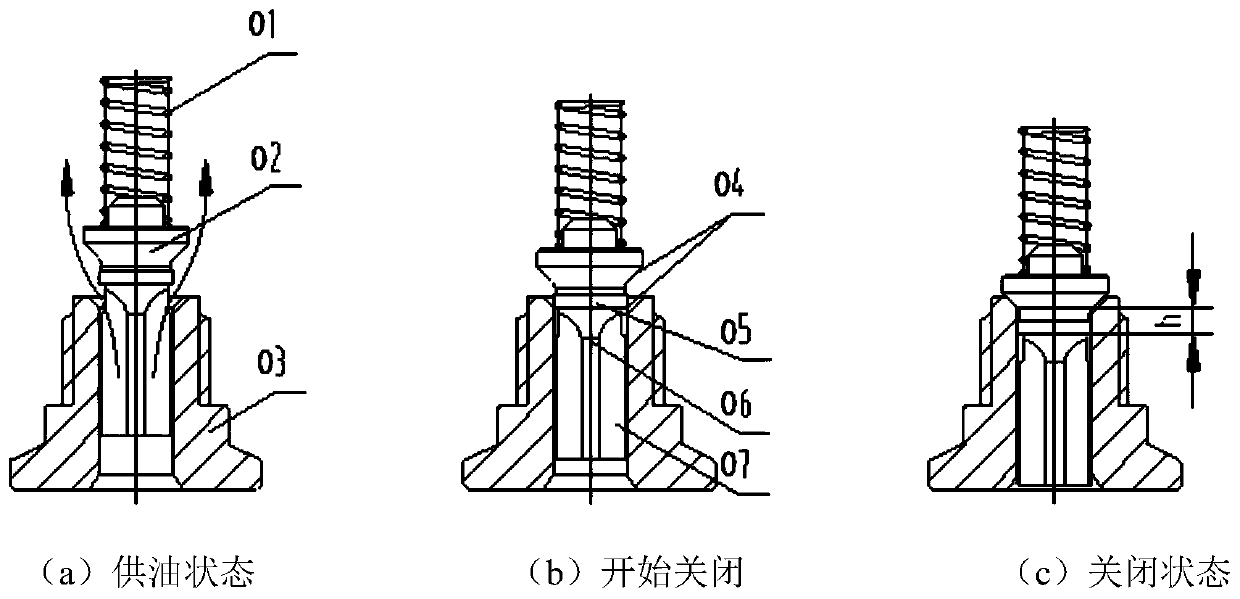

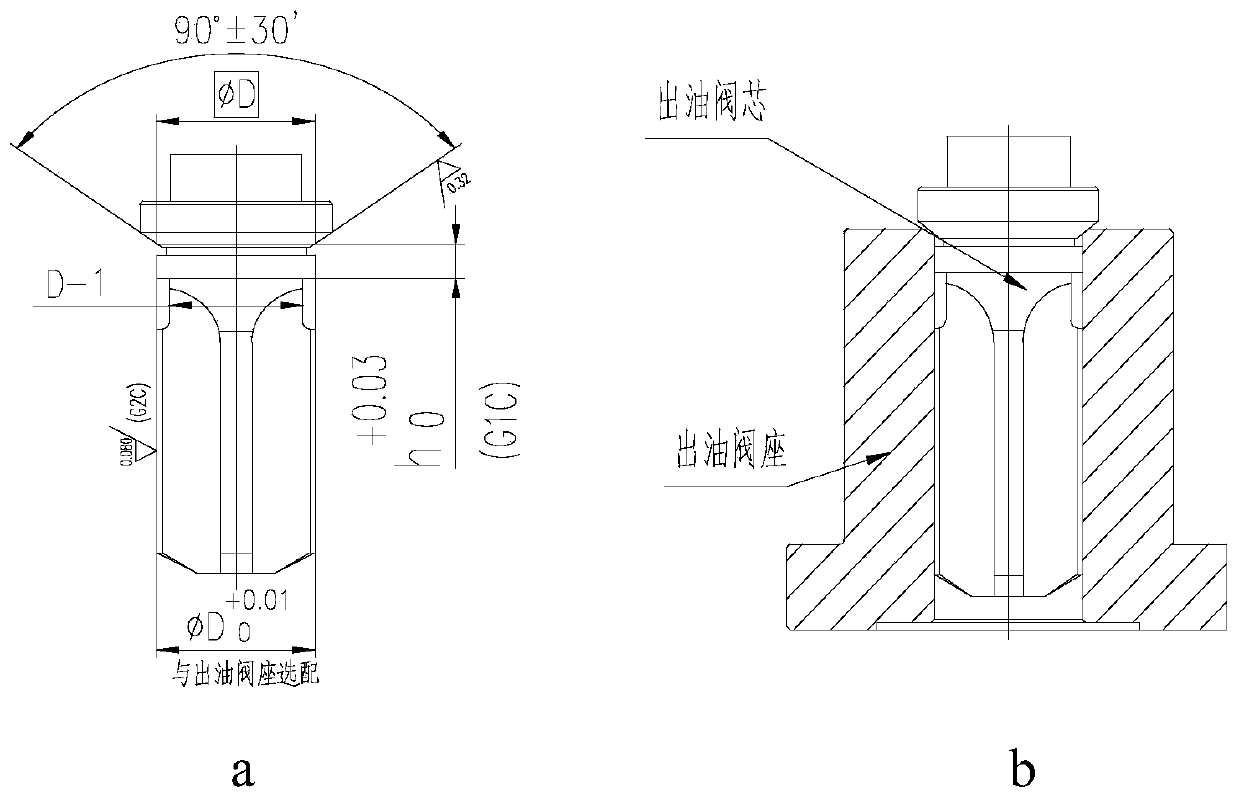

[0030]The invention adopts the sample comparison method, applies the mechanism design method, and designs a special measuring head through the leverage principle to realize the precise measurement of the decompression stroke of the oil outlet valve and the measurement of the decompression stroke of the rough-semi-finished-finishing process of the product, and at the same time Meet the same type of product measurement, fast and convenient replacement, save time and effort, and easy to operate. In view of the large number of key parts sample holders and lever assemblies used and the high frequency of measurement, the material, heat treatment and technical indicators are optimized respectively to ensure accurate indicator d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com