Intensity self-calibration multi-channel X-ray imaging system and application method

An imaging system and X-ray technology, applied in the field of X-ray imaging, can solve the problems of difficult installation and adjustment, many channel scanning tasks, and long time-consuming, and achieve the effect of shortening the research and development cycle, improving the calibration efficiency, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

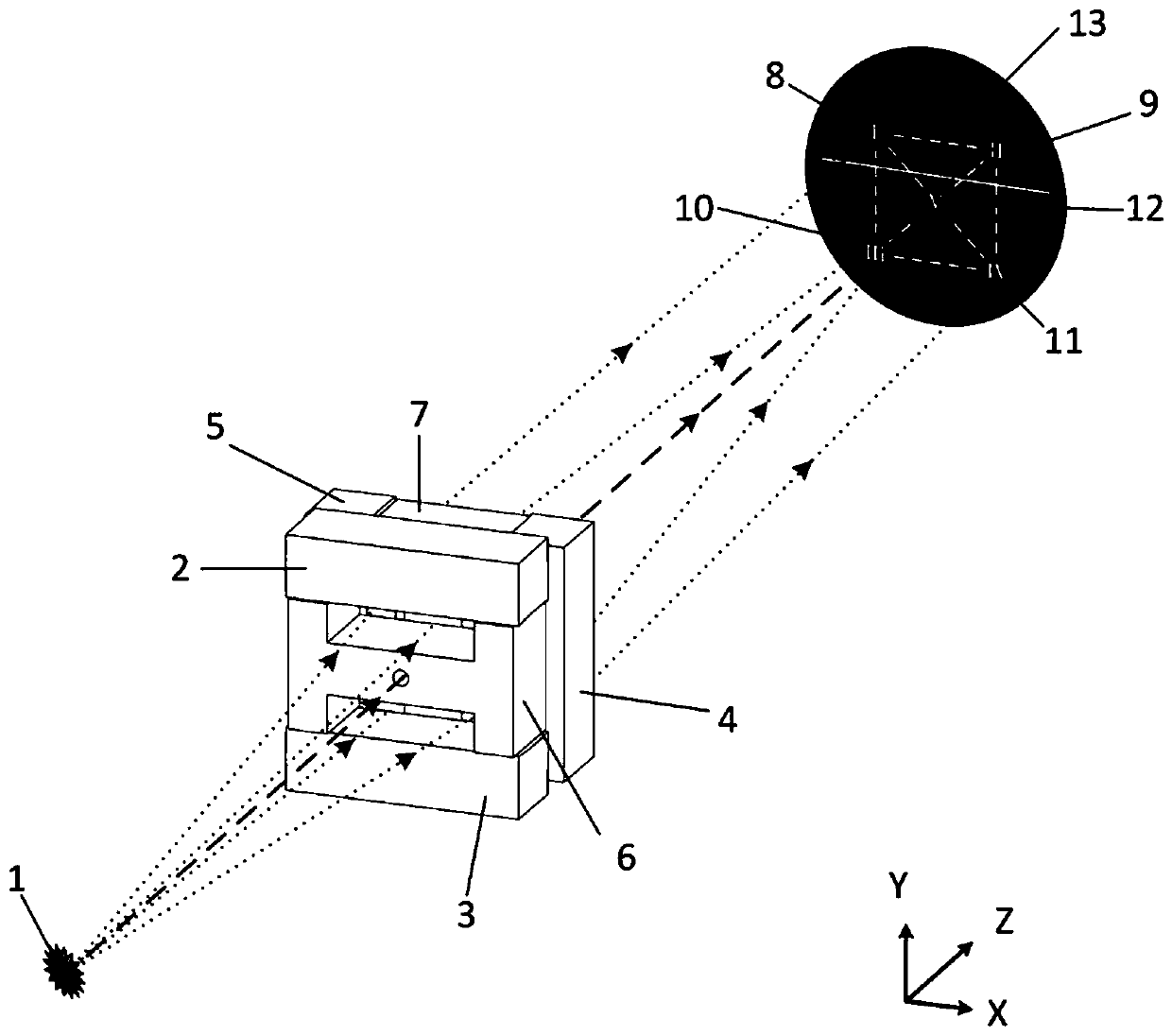

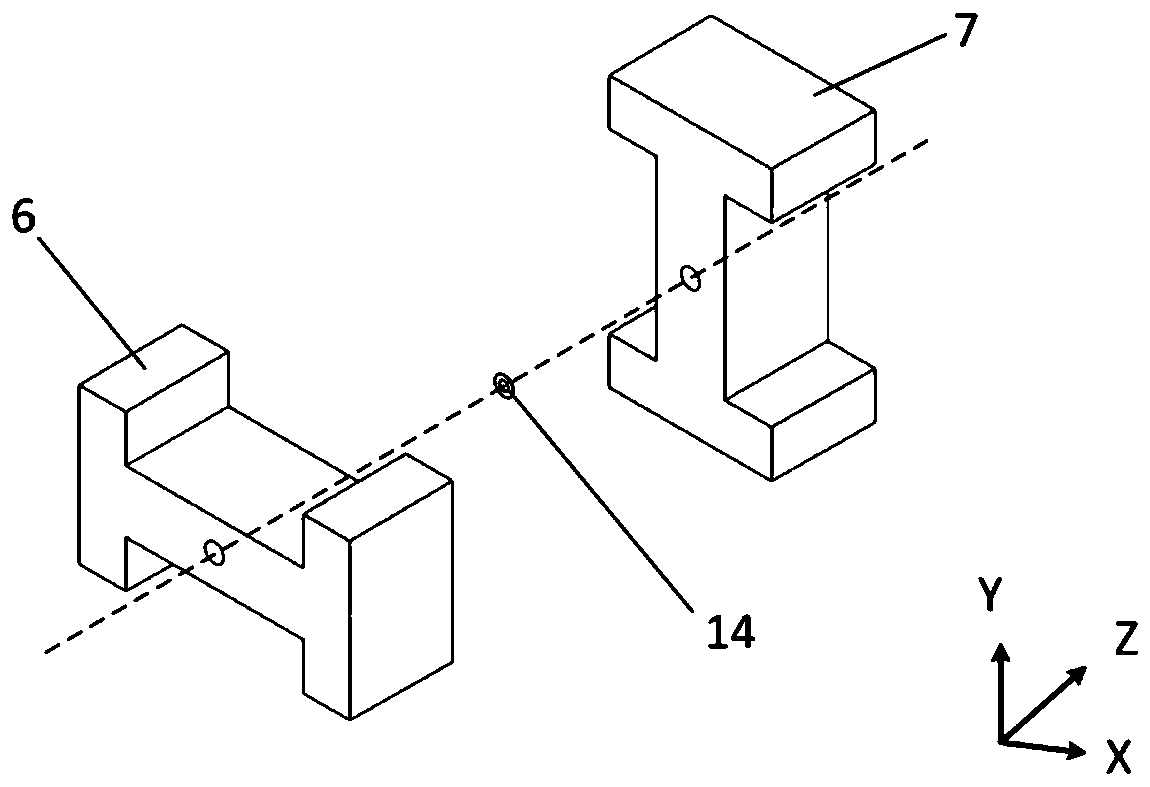

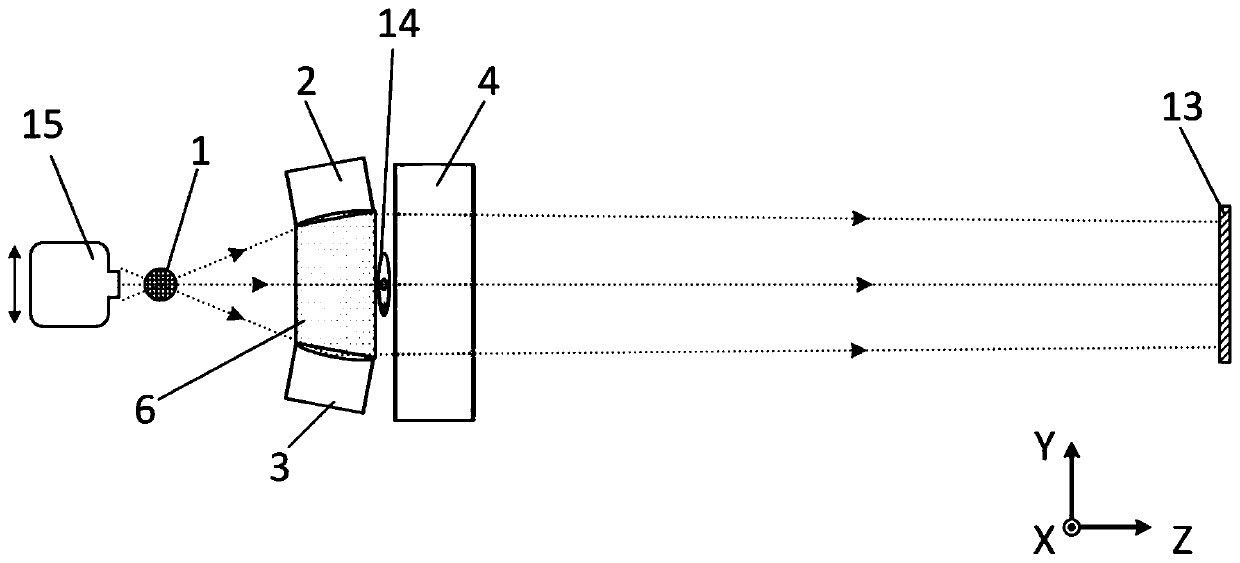

[0046] Select the first transverse cylindrical reflector 2, the second transverse cylindrical reflector 3, the first longitudinal cylindrical reflector 4 and the second longitudinal cylindrical reflector 5 with a radius of curvature of 50m, and the horizontal I-shaped optical cone The core 6 and the vertical I-shaped optical cone core 7 form a four-channel KB microscope. The initial structural parameters of the multi-channel X-ray imaging system are shown in Table 1:

[0047] Table 1 Initial structural parameters of the multi-channel X-ray imaging system

[0048]

[0049] The surfaces of the first transverse cylindrical reflector 2, the second transverse cylindrical reflector 3, the first longitudinal cylindrical reflector 4 and the second longitudinal cylindrical reflector 5 adopt double-layer X-ray film, and one layer is 30nm thickness The Pt film can be adapted to the energy points of 2.5, 6 and 8keV, and the single mirror reflectance is above 70%, which can meet the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com