Power supply array health management system

A health management system and power supply technology, which is applied in the field of power array health management system, can solve the problems of power array cooling fans without adaptive adjustment, power array output voltage without adaptive adjustment, and poor online maintenance of power supply status. Achieve the effect of reducing impact surge, reducing impact and reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

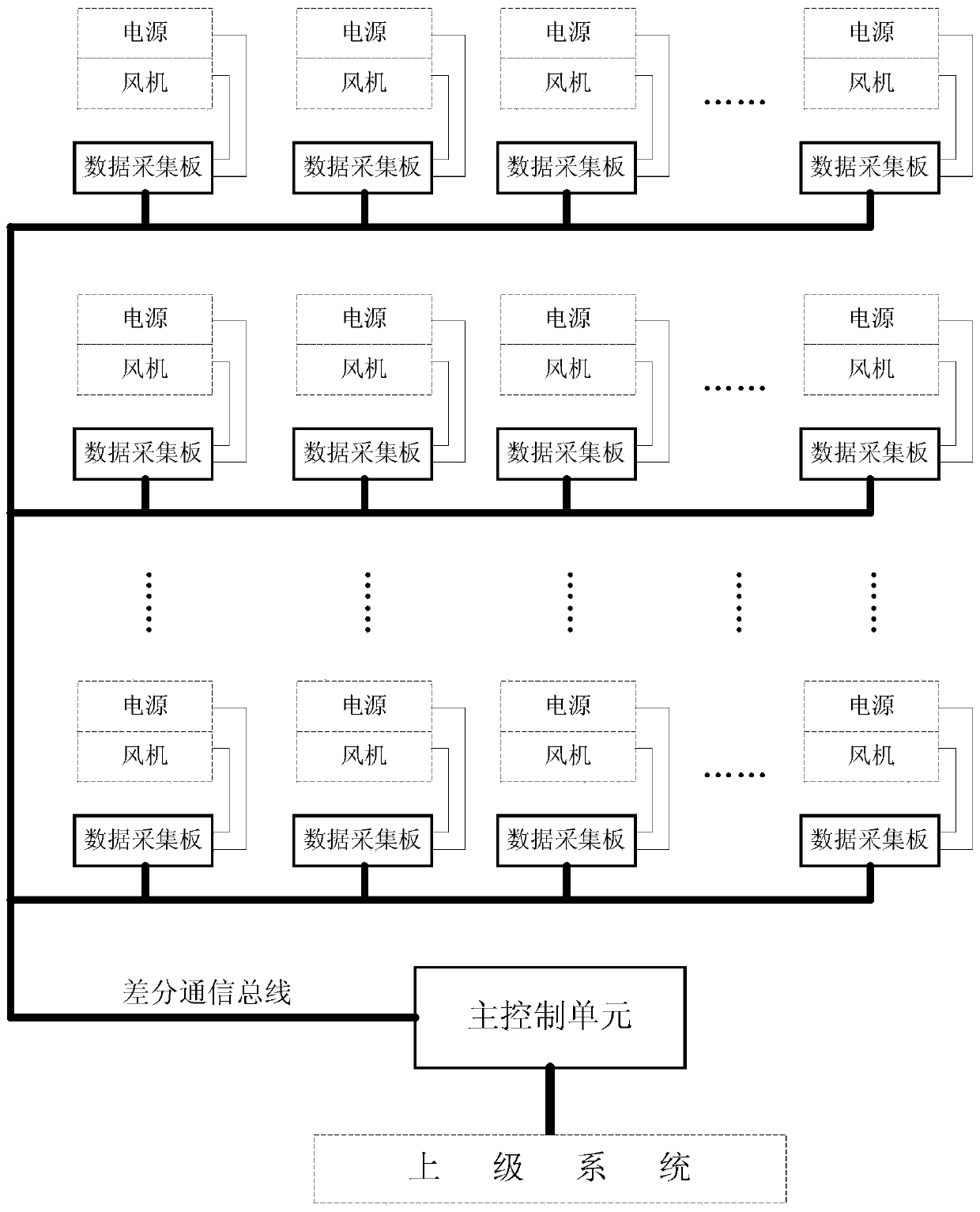

[0047] A power array health management system of the present invention includes a main control unit, a plurality of data acquisition boards, and a differential communication bus, and each data acquisition board is installed in combination with each power supply and fan in the power array, and the main control unit and each The data acquisition board is connected through a differential communication bus.

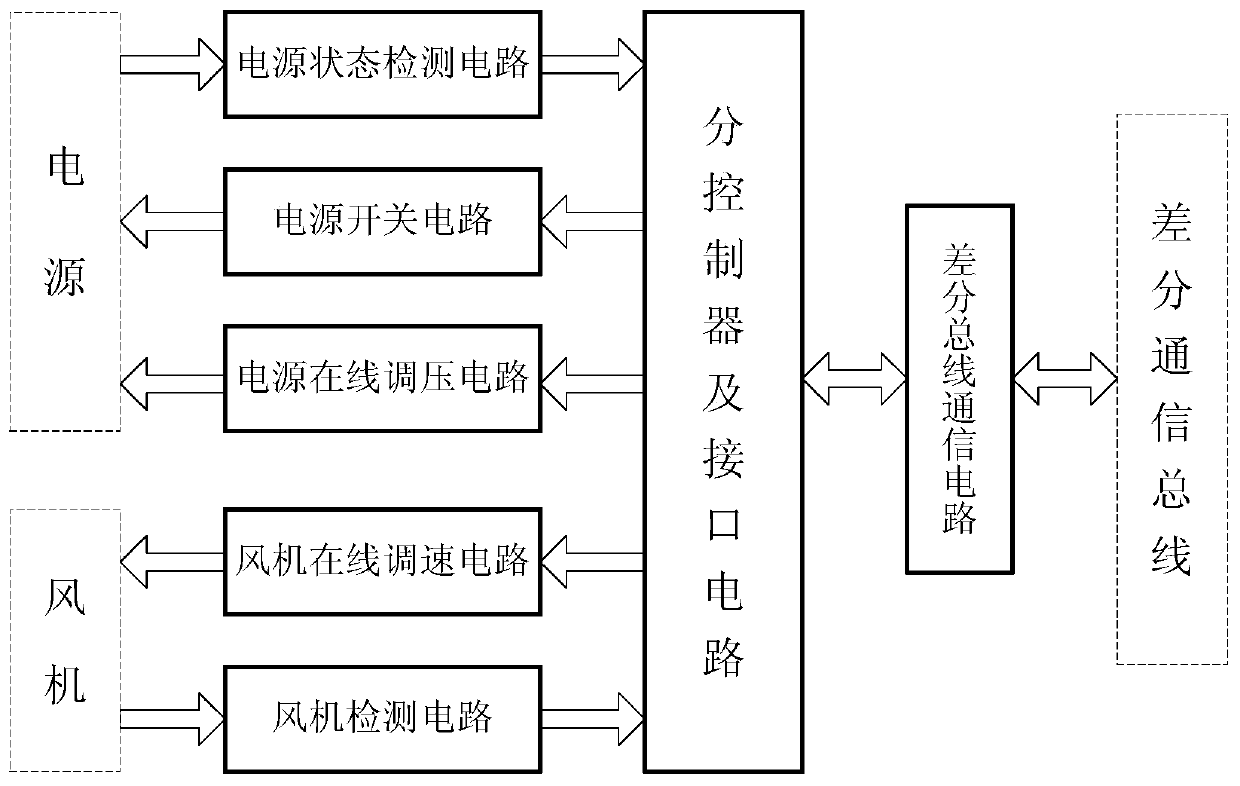

[0048] First of all, the present invention improves the data acquisition board: on the basis of the original data acquisition function, the power supply online voltage regulation circuit, the power switch circuit, and the fan online speed regulation circuit are added, so that the original single data acquisition function is added. Hardware condition guarantee for online maintenance of the power supply.

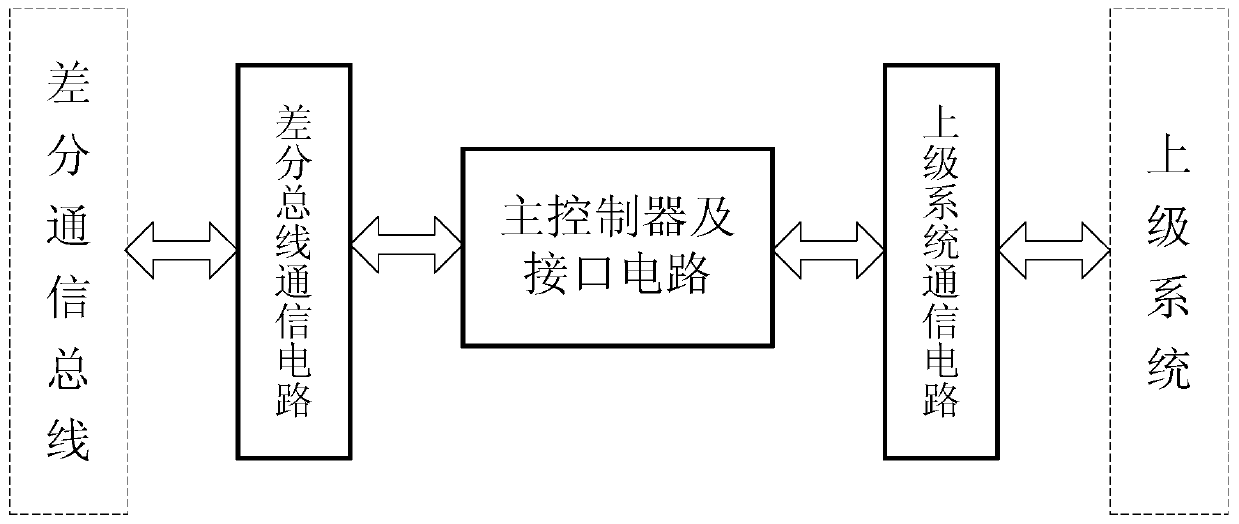

[0049] Secondly, the present invention improves the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com