A high strength long open time polyurethane reactive hot melt

A technology of hot-melt adhesives and adhesives, applied in polyurea/polyurethane adhesives, adhesive types, polyurea/polyurethane coatings, etc., can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

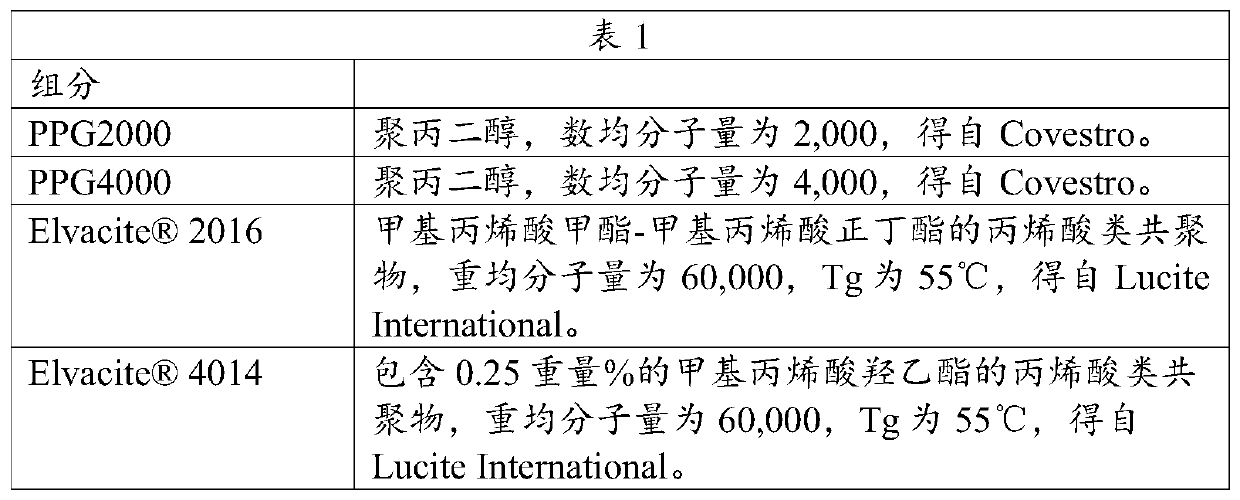

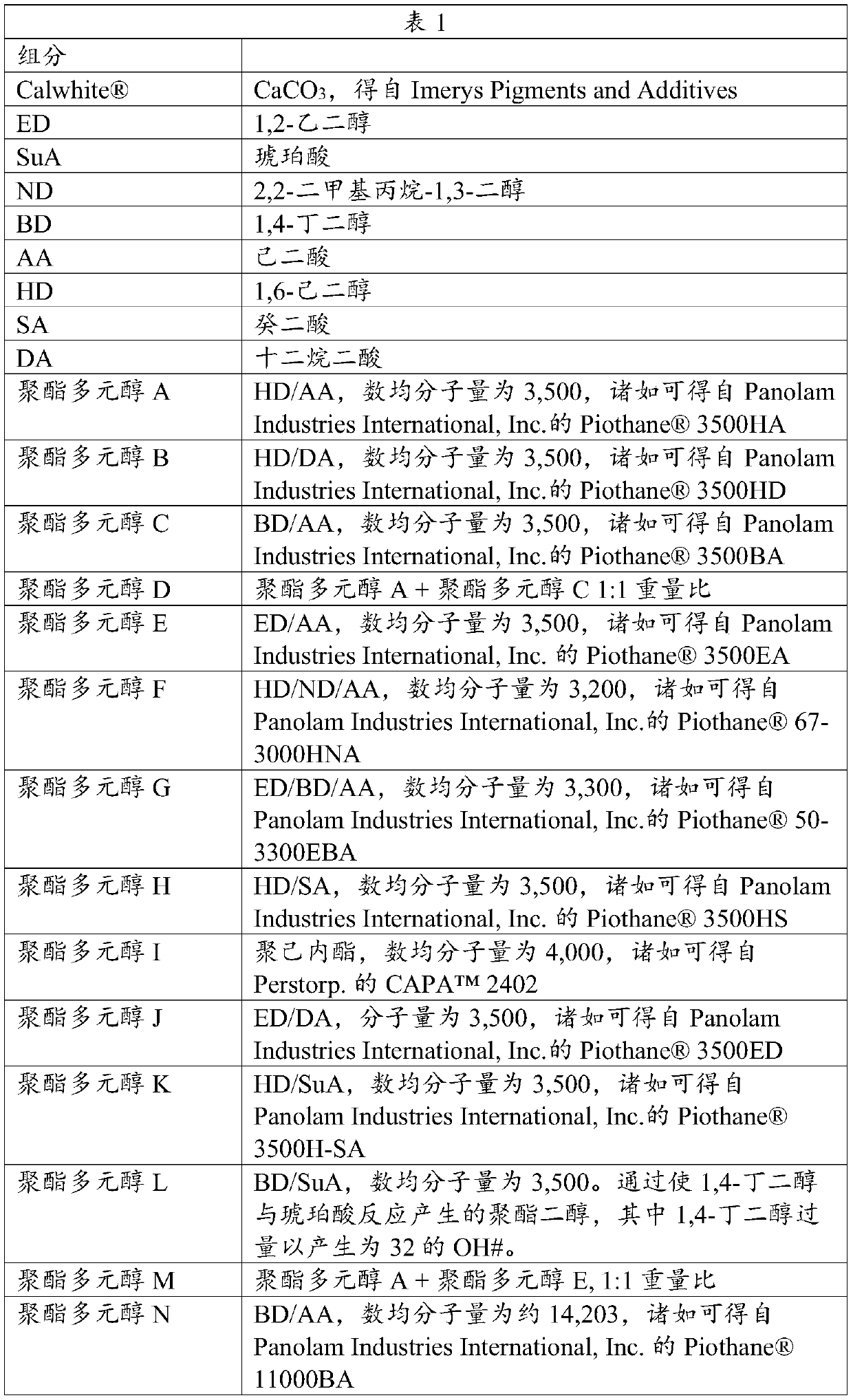

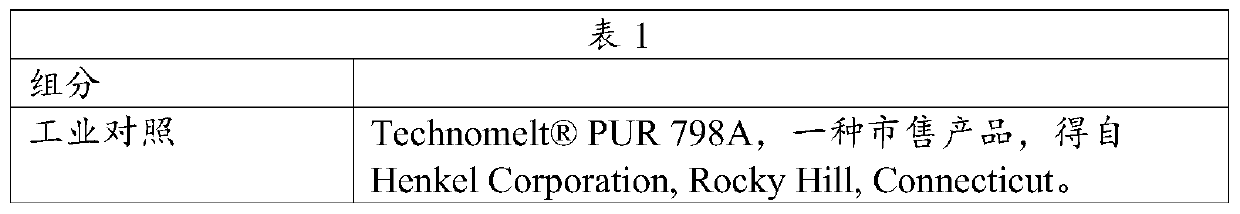

[0059] The following components in Table 1 were used in the following examples.

[0060]

[0061]

[0062]

[0063] The following general formulations (Table 2A) were used to prepare Adhesive Examples 1-15 shown in Table 3 below. Table 2B shows the components used in Example 16 below, which is similar to Example 3 except that there is no filler Except for the industrial control, all polyurethane reactive hot melt adhesive compositions in the following examples were prepared by the following method, and only the polyester polyol was changed as described in Table 3. The process is as follows: add all ingredients except polyisocyanate 4,4'-MDI to a mixer and heat under stirring; then dehydrate the mixture under vacuum at about 110°C to about 130°C for 60 minutes; then 4, 4'-MDI was added to the mixture and the mixture was reacted at 130° C. for 75 minutes; the formed prepolymer was then sealed in a moisture-proof container.

[0064]

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com