Method and system for monitoring egg laying performance of laying hen zone of cage-rearing laying hens

An egg-laying performance and monitoring system technology, applied in poultry industry, measuring devices, poultry cages or houses, etc., to save costs and reduce labor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

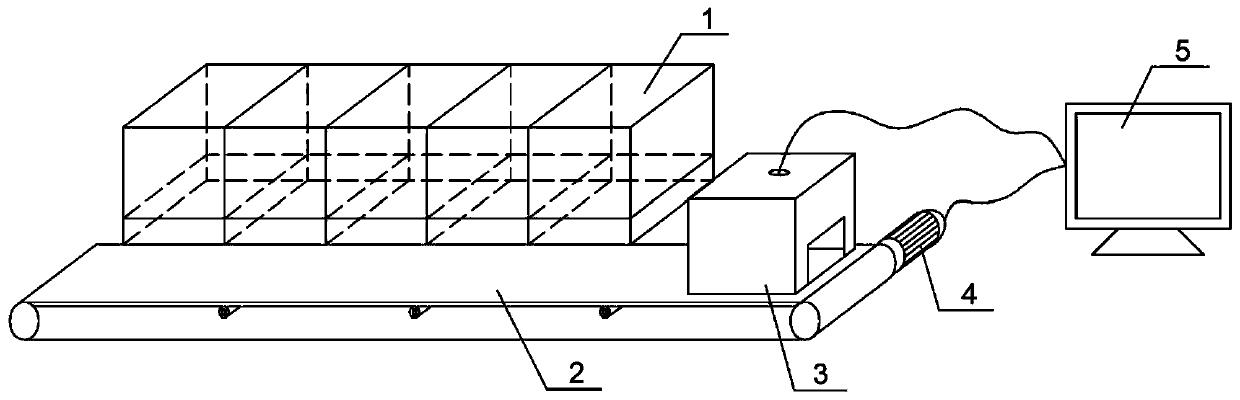

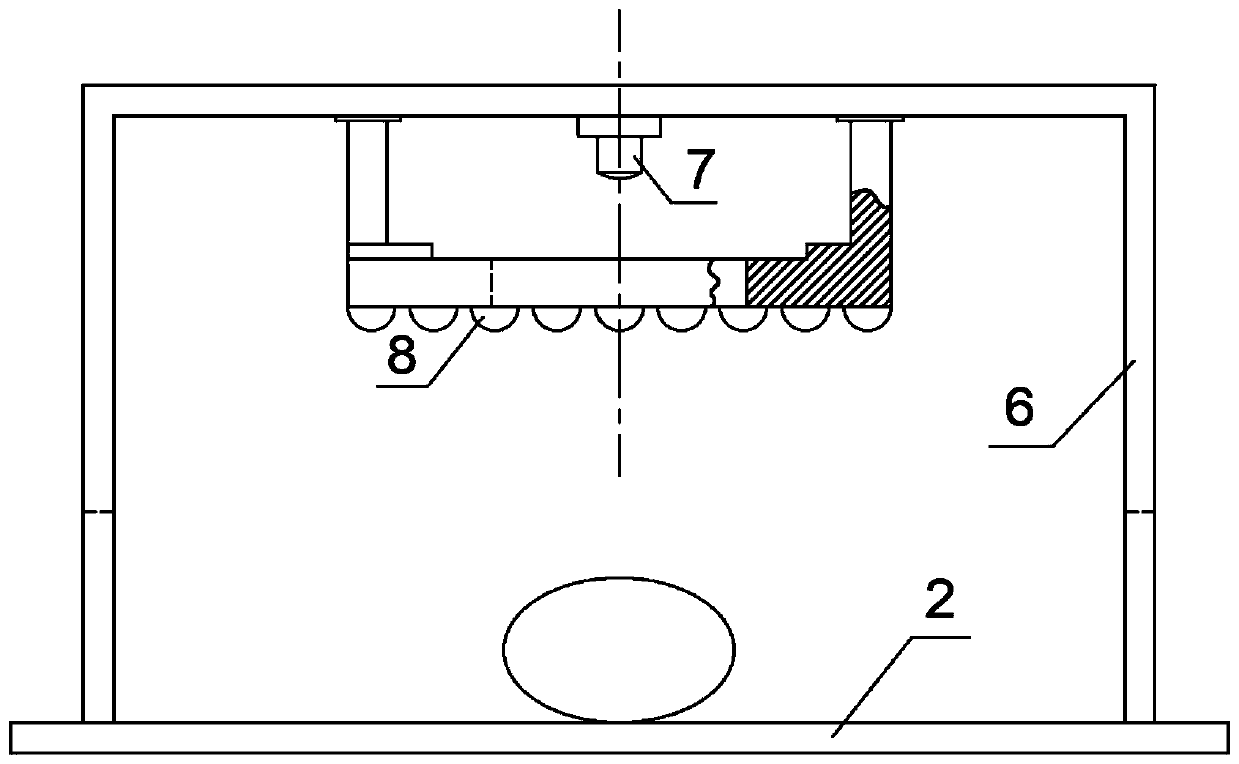

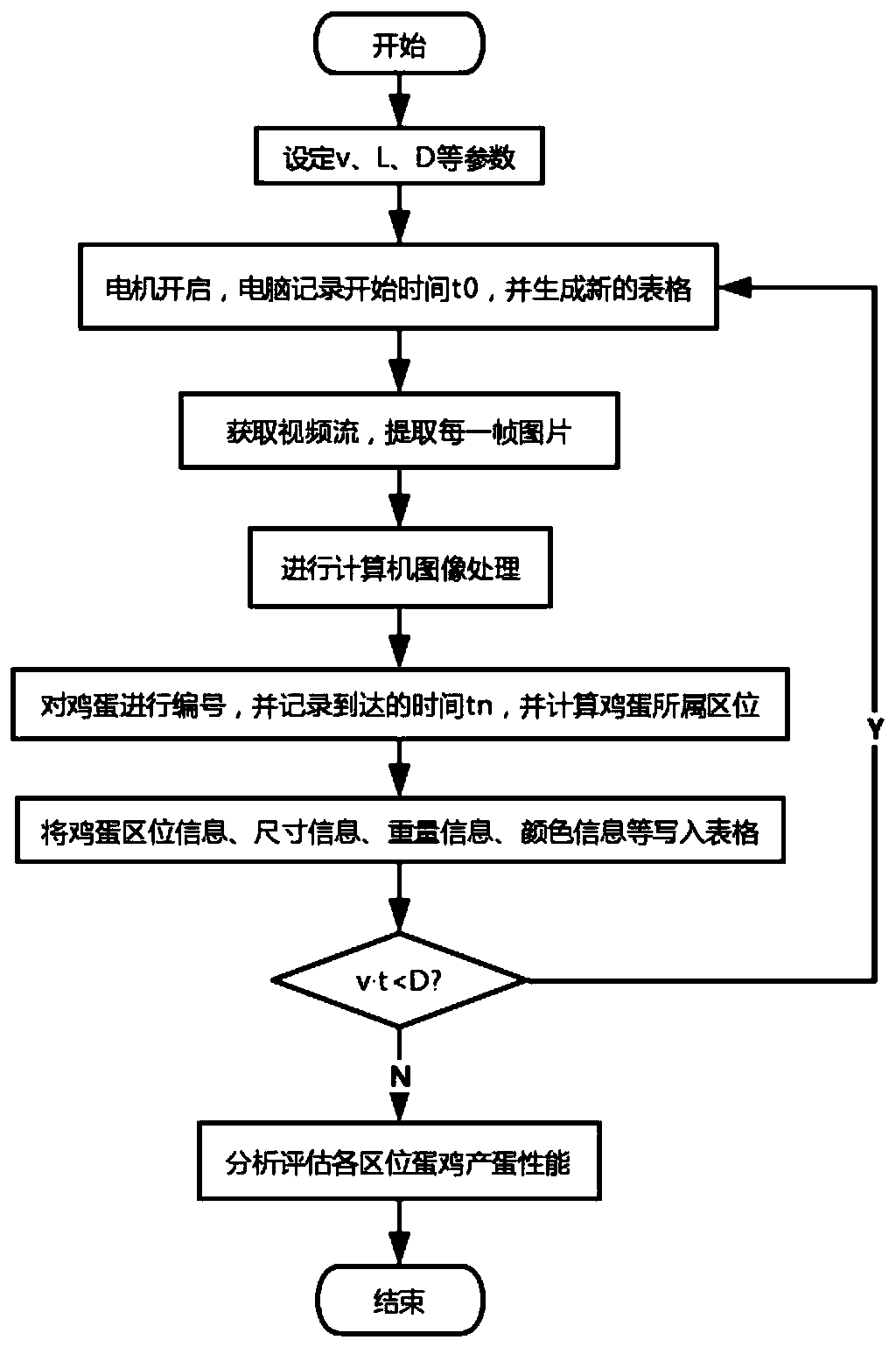

[0042] Such as figure 1 and figure 2 As shown, the specific implementation system includes a chicken cage 1, a conveyor belt 2, a machine vision detection device 3, a CCD camera 7 and a motor 4; the chicken cage 1 is located above the conveyor belt 2, and the conveyor belt 2 is installed below the chicken cage 1, and the conveyor belt 2 is used to accept And transport the eggs, the eggs laid by the chickens in the chicken coop 1 leak from the bottom of the chicken coop 1 and fall onto the conveyor belt 2 and are transported along the conveyor belt 2. A plurality of chicken cages 1 are included, and the plurality of chicken cages 1 are arranged along the conveying direction of the conveyor belt 2 .

[0043] One end of the conveyor belt 2 is installed and connected to a motor 4, and the motor 4 drives the conveyor belt 2 to work; the machine vision det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com