Pretreatment device for petroleum-contaminated soil remediation

A pretreatment device and soil remediation technology, applied in the restoration of contaminated soil, etc., can solve the problems of complex operation, general treatment effect, time-consuming and labor-intensive, etc., and achieve the effect of ensuring the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

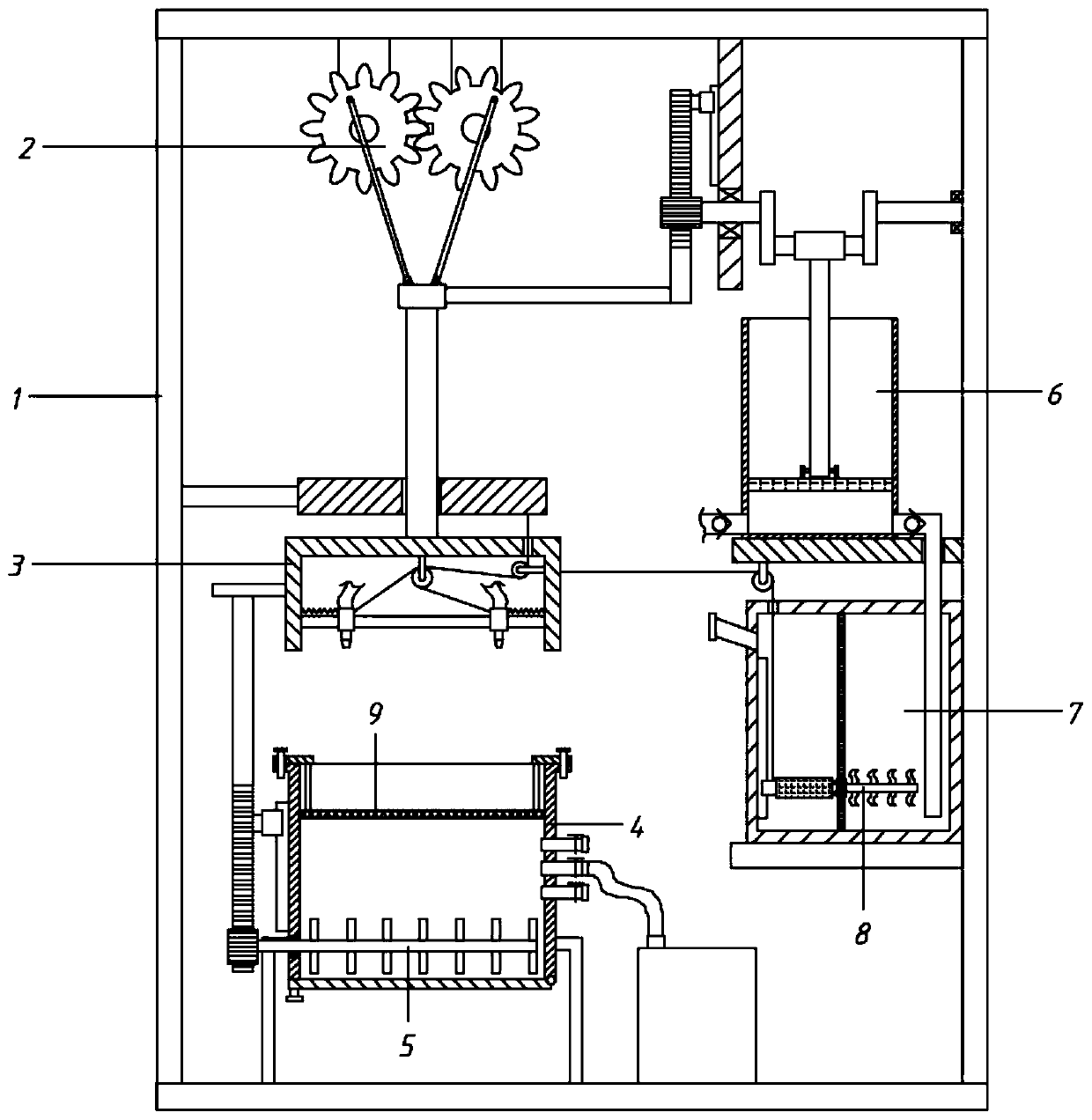

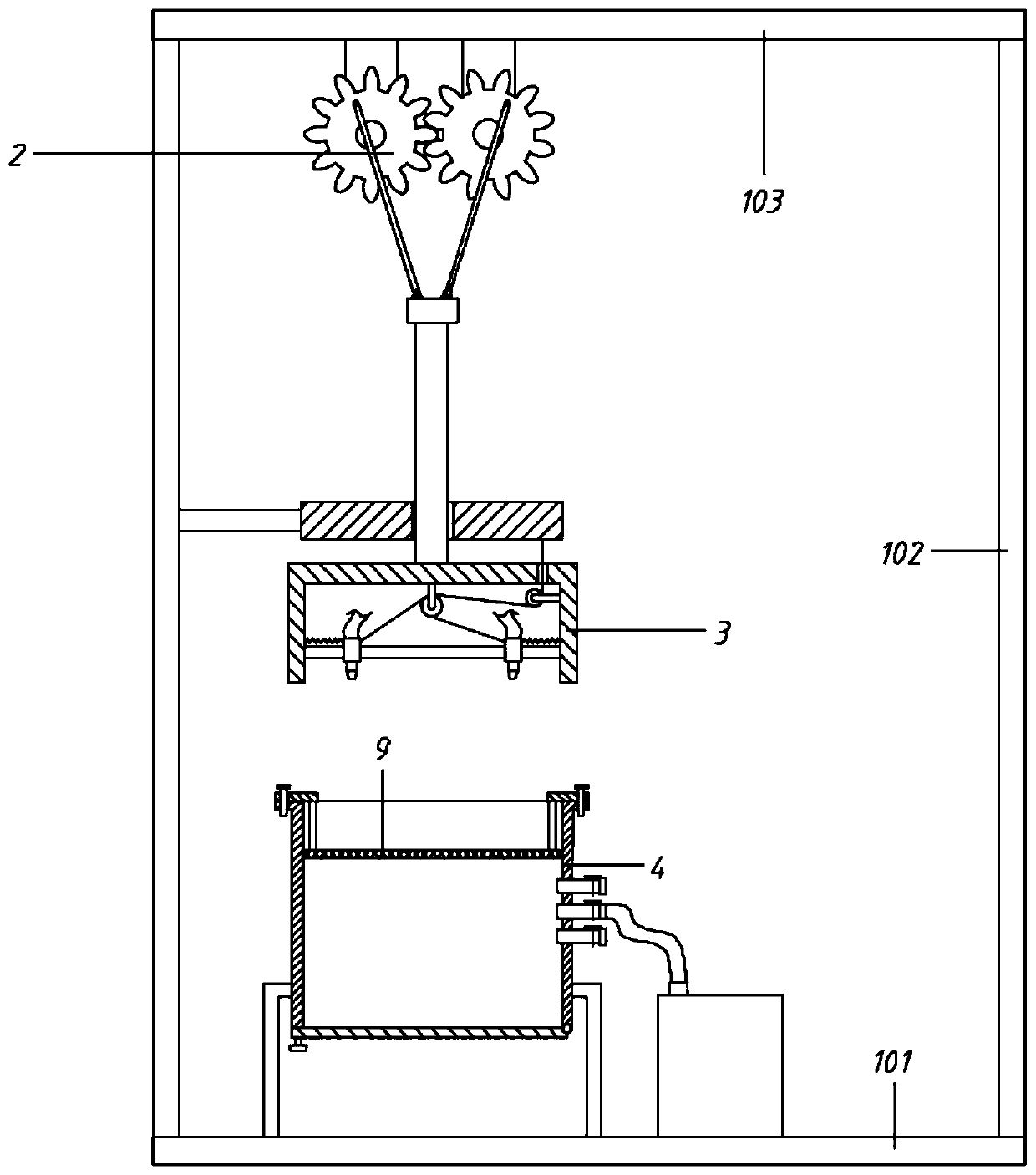

[0065] A pretreatment device for remediation of petroleum-contaminated soil, comprising a frame 1, a lifting assembly 2, a spraying assembly 3, a separating assembly 4, and a filtering assembly 9;

[0066] The frame 1 includes a bottom plate 101, a side plate 102 and a top plate 103. The side plate 102 is symmetrically fixed to the left and right ends of the bottom plate 101, and the top plate 103 is connected to the top of the side plate 102; There is a spraying assembly 3; the separation assembly 4 is arranged on the bottom plate 101 corresponding to the spraying assembly 3; a filter assembly 9 is arranged on the top of the separation assembly 4.

Embodiment 2

[0068] A pretreatment device for remediation of petroleum-contaminated soil, comprising a frame 1, a lifting assembly 2, a spraying assembly 3, a separating assembly 4, and a filtering assembly 9;

[0069] The frame 1 includes a bottom plate 101, a side plate 102 and a top plate 103. The side plate 102 is symmetrically fixed to the left and right ends of the bottom plate 101, and the top plate 103 is connected to the top of the side plate 102; There is a spraying assembly 3; the separation assembly 4 is arranged on the bottom plate 101 corresponding to the spraying assembly 3; a filter assembly 9 is arranged on the top of the separation assembly 4.

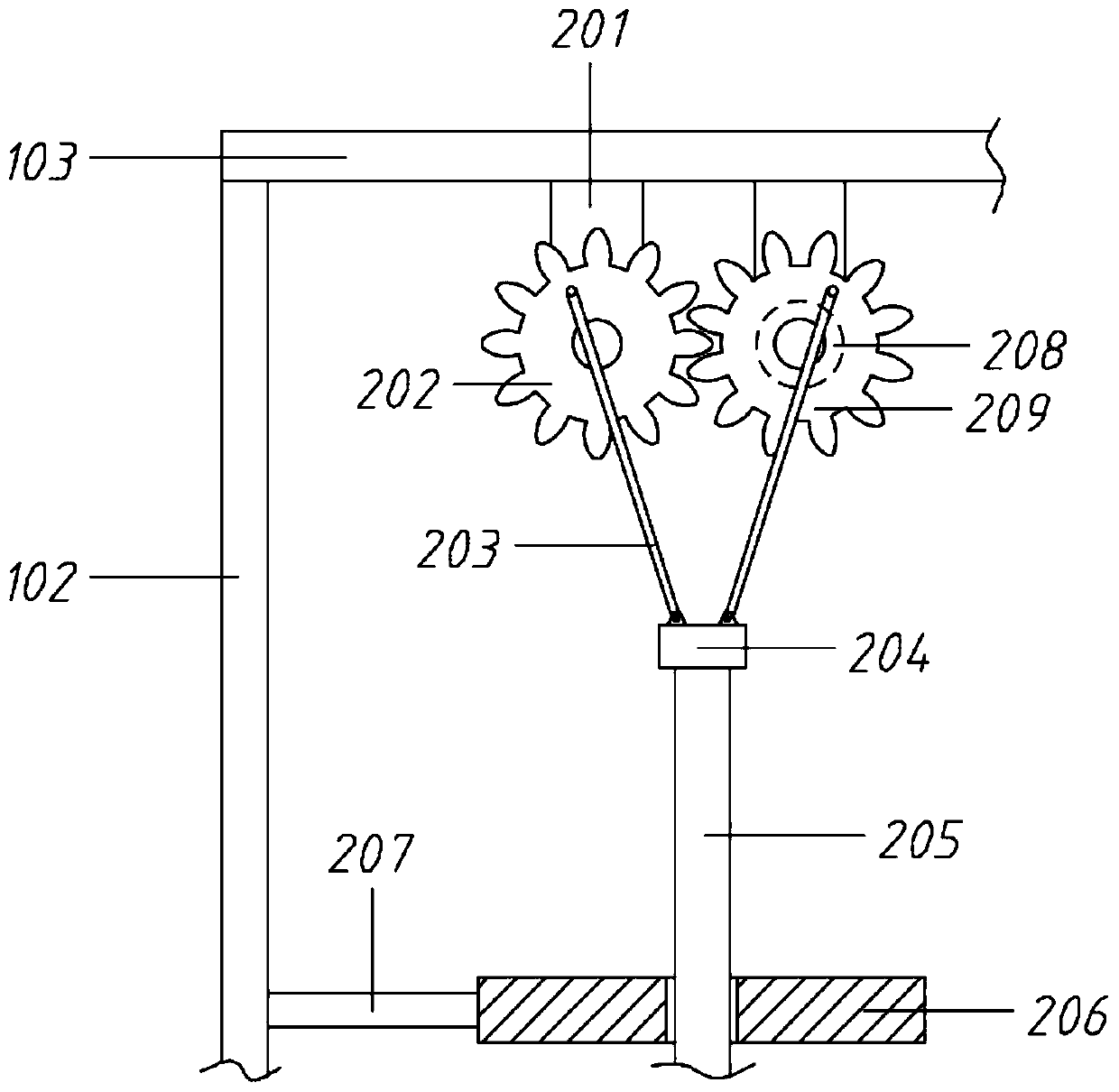

[0070] Wherein, the lifting assembly 2 includes a mounting seat 201, a gear 202, a rotating rod 203, a top block 204, a lifting rod 205, a guide seat 206, a support rod 207, a servo motor 208 and a gear 209;

[0071] Top plate 103 bottom surface is equipped with two mounting bases 201, and a servo motor 208 is equipped with at the...

Embodiment 3

[0086] On the basis of embodiment 2,

[0087] It also includes a stirring assembly 5, which includes a No. 1 rod 501, a No. 1 rack 502, a No. 1 driven gear 505, a No. 1 rotating shaft 506 and a type of stirring rod 507;

[0088] The left side of U-shaped frame 301 is connected with No. 1 bar 501, and No. 1 bar 501 is connected with No. 1 rack 502 downwards. No. 1 rack 502 is located on the left side of separation box 401; Evenly equipped with a class of stirring rods 507 on the 506; the left end of the first rotating shaft 506 stretches out the separation box 401 and the No. 1 driven gear 505 is housed, and the No. 1 driven gear 505 cooperates with the No. 1 rack 502.

[0089] Specifically, when the U-shaped frame 301 moves up and down, it also moves up and down with the No. 1 rack 502, so that the No. 1 rotating shaft 506 is rotated through the No. 1 driven gear 505, and the small particle soil and the Stir the oil to break it up, make the soil and hot water fully contact, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com