A low-temperature hot-press packaging machine

A packaging machine, low temperature technology, applied in the field of intelligent manufacturing, can solve the problems of increasing product cost, time-consuming and laborious, etc., and achieve the effect of extending shelf life, improving product quality, and improving efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

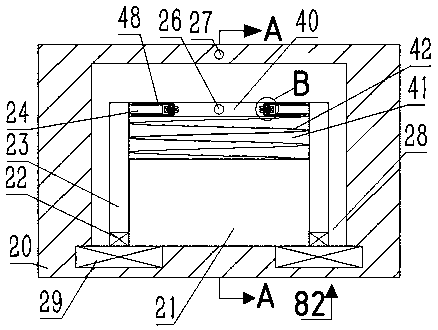

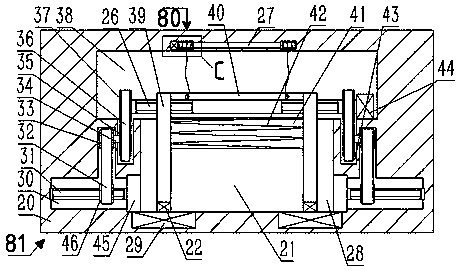

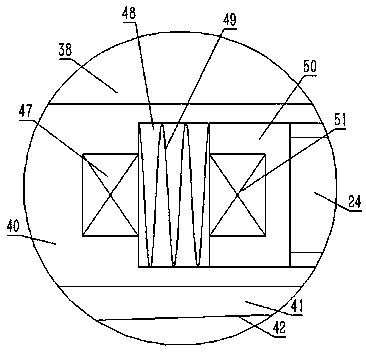

[0018] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

[0019] refer to Figure 1-4 , a low-temperature hot-press packaging machine according to an embodiment of the present invention includes a body 20, a push-in space 28 is provided inside the body 20, and a control space 38 is provided on the upper side of the push-in space 28, the The fixed block 40 is slidably installed in the control space 38, and the pulling part 80 for controlling the position of the fixed block 40 is arranged in the control space 38. Insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com