Intelligent warehouse wall cleaning machine for cement warehouse

A technology of intelligent warehouse wall and warehouse cleaning machine, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of poor flexibility, easy shaking, poor stability, etc., to extend life, prevent fatigue and break, and enhance stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

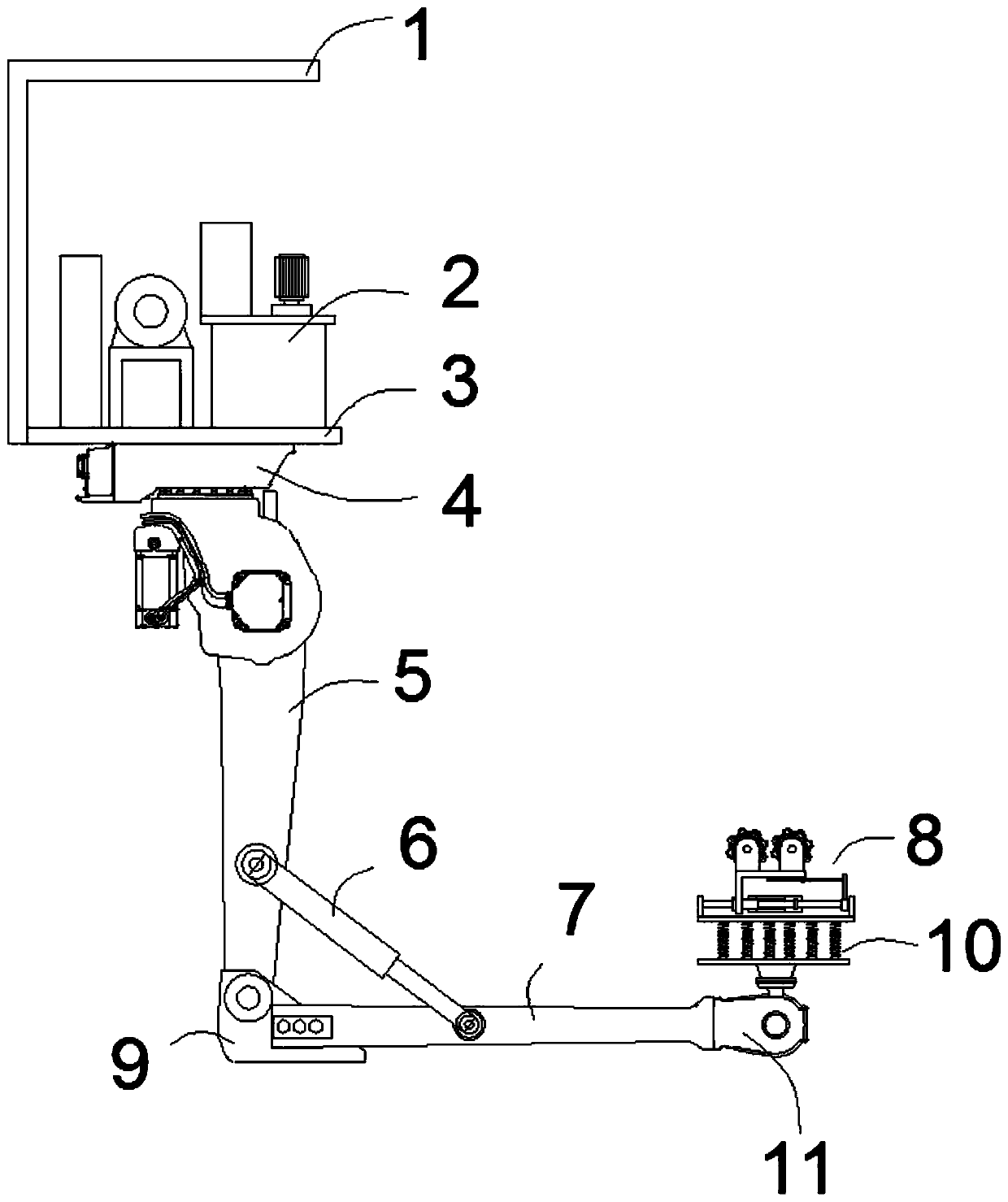

[0032] Such as Figures 1 to 3 As shown, this embodiment provides an intelligent warehouse wall cleaning machine for cement warehouses, including a fixed plate 3, a mechanical arm mechanism is arranged below the fixed plate 3, and a control mechanism is arranged above the fixed plate 3 The controller 2 that the arm mechanism rotates. The end of the mechanical arm mechanism is movably provided with an anti-vibration type warehouse clearing mechanism. 10 position adjustable warehouse clearing assembly 8.

[0033]The mechanical arm mechanism includes a rotating base 4 fixed below the fixed plate 3, the rotating base 4 is hinged with a mechanical arm 5 through a steering gear, and the end of the mechanical arm 5 is connected with a connecting block 9 through a hinge mechanism. The block 9 is opened and disassembled to be provided with a mechanical arm two 7, two synchronous hydraulic cylinders 6 are arranged between the mechanical arm one 5 and the mechanical arm two 7, and the e...

Embodiment 2

[0036] This embodiment is further optimized on the basis of embodiment 1, specifically:

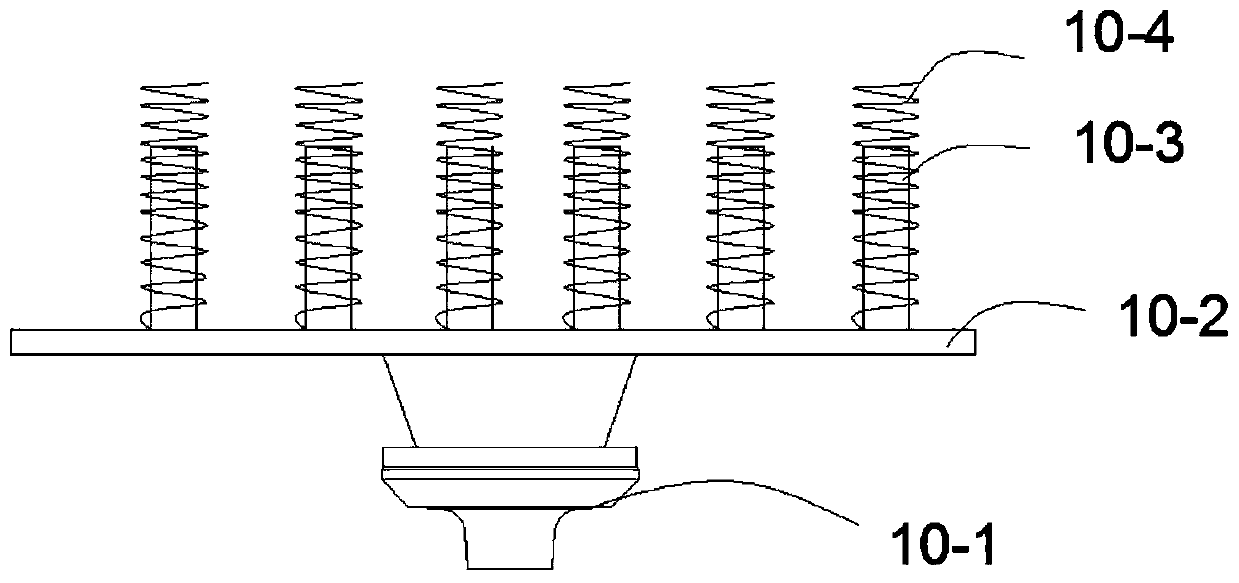

[0037] The shock absorbing mechanism 10 includes a connection plate 10-1 hinged to the installation mechanism 11, a support base plate 10-2 is fixedly arranged on the connection plate 10-1, and a plurality of guide columns 10-2 are evenly distributed on the support base plate 10-2. 3. Each guide column 10-3 is equipped with a damping spring 10-4, one end of the damping spring 10-4 is fixedly connected to the support base plate 10-2, and the other end of the damping spring 10-4 is connected to the warehouse cleaning assembly 8 connections.

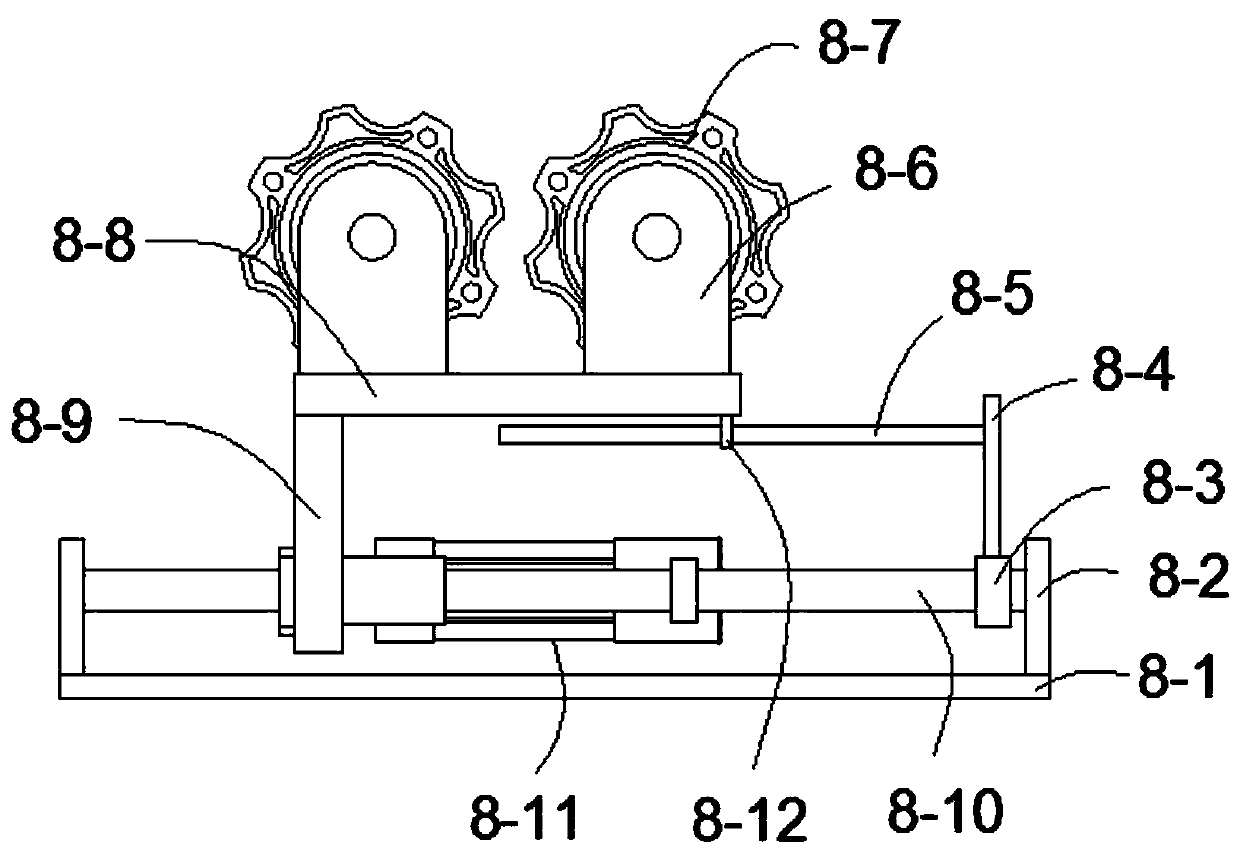

[0038] The warehouse clearing assembly 8 includes a U-shaped installation groove fixedly connected with the shock absorbing mechanism 10, and the U-shaped installation groove includes a bottom horizontal plate 8-1 and side plates 8-2 arranged on both sides of the bottom horizontal plate 8-1, A grinding mechanism and a position driving mechanism for dr...

Embodiment 3

[0041] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically as follows:

[0042] The position driving mechanism includes a transverse support rod 8-10 arranged between two side plates 8-2, and a sliding mounting seat 8-9 is set on the described transverse support rod 8-10, and the transverse support rod 8 -10 is provided with a cylinder 8-11 that drives the sliding mounting seat 8-9 to reciprocate on the lateral support rod 8-10, the sliding mounting seat 8-9 is provided with a grinding mechanism mounting table 8-8, and the lateral supporting rod 8-10 10 is also fixedly provided with a guide support assembly.

[0043] The grinding mechanism includes a mounting frame 8-6 fixed on the grinding mechanism mounting table 8-8, the mounting frame 8-6 is provided with a descaling power head 8-7, and the descaling power head 8-7 is provided with grinding teeth.

[0044] The guide support assembly includes an installation block 8-3 fixed on the transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com