Regeneration method and gas distributor for molecular sieve in synthetic gas cooling box

A gas distribution plate, molecular sieve technology, applied in separation methods, selection of absorbent solid gas purification, gas treatment and other directions, can solve the problems of Fischer-Tropsch side reactions, potential safety hazards, molecular sieve failure, etc., to achieve uniform airflow distribution, Improve the effect of adsorption and regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

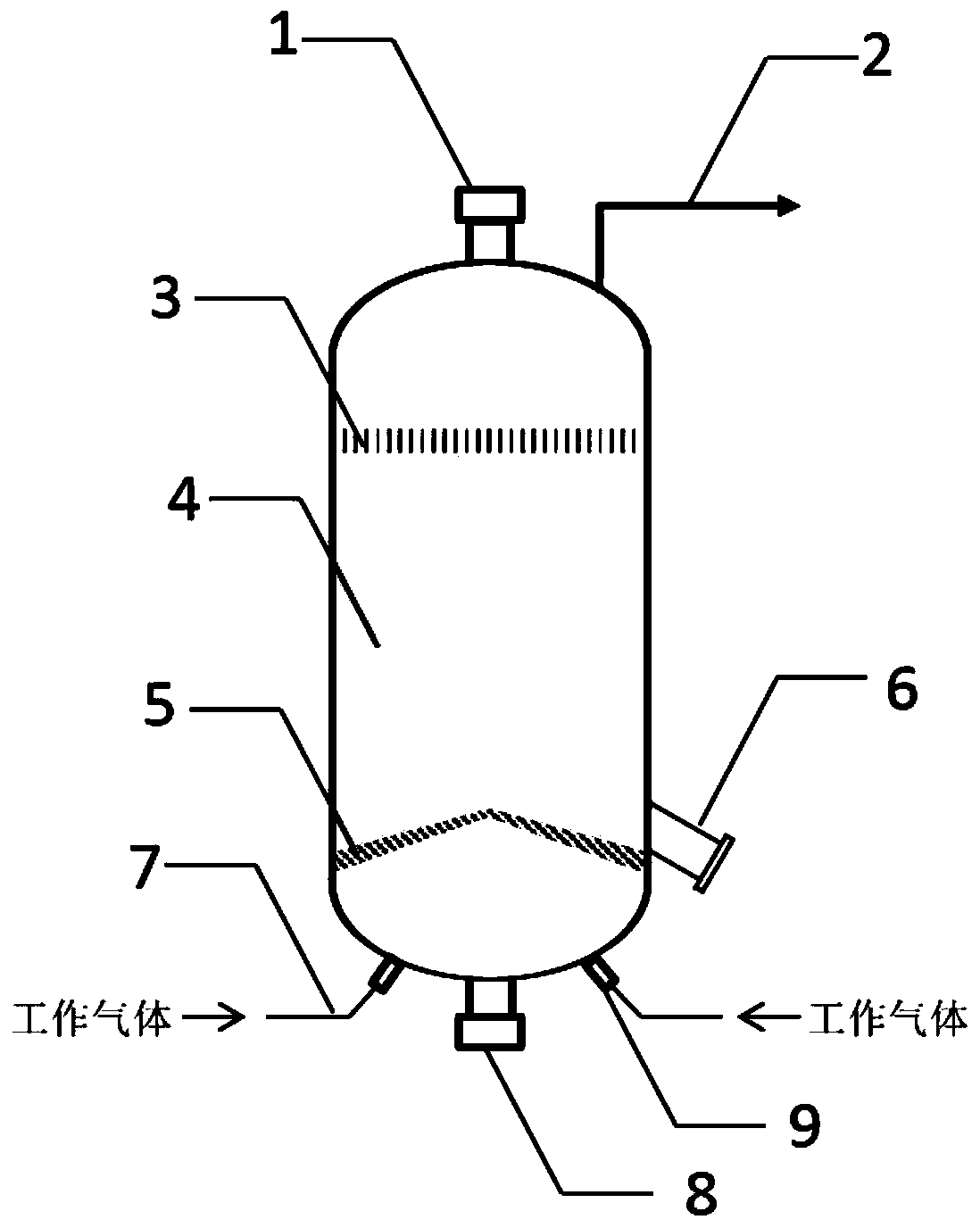

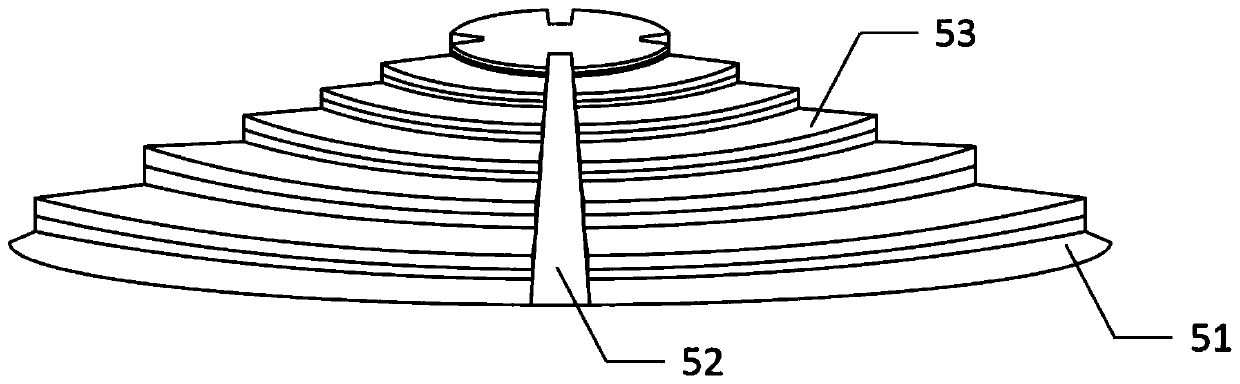

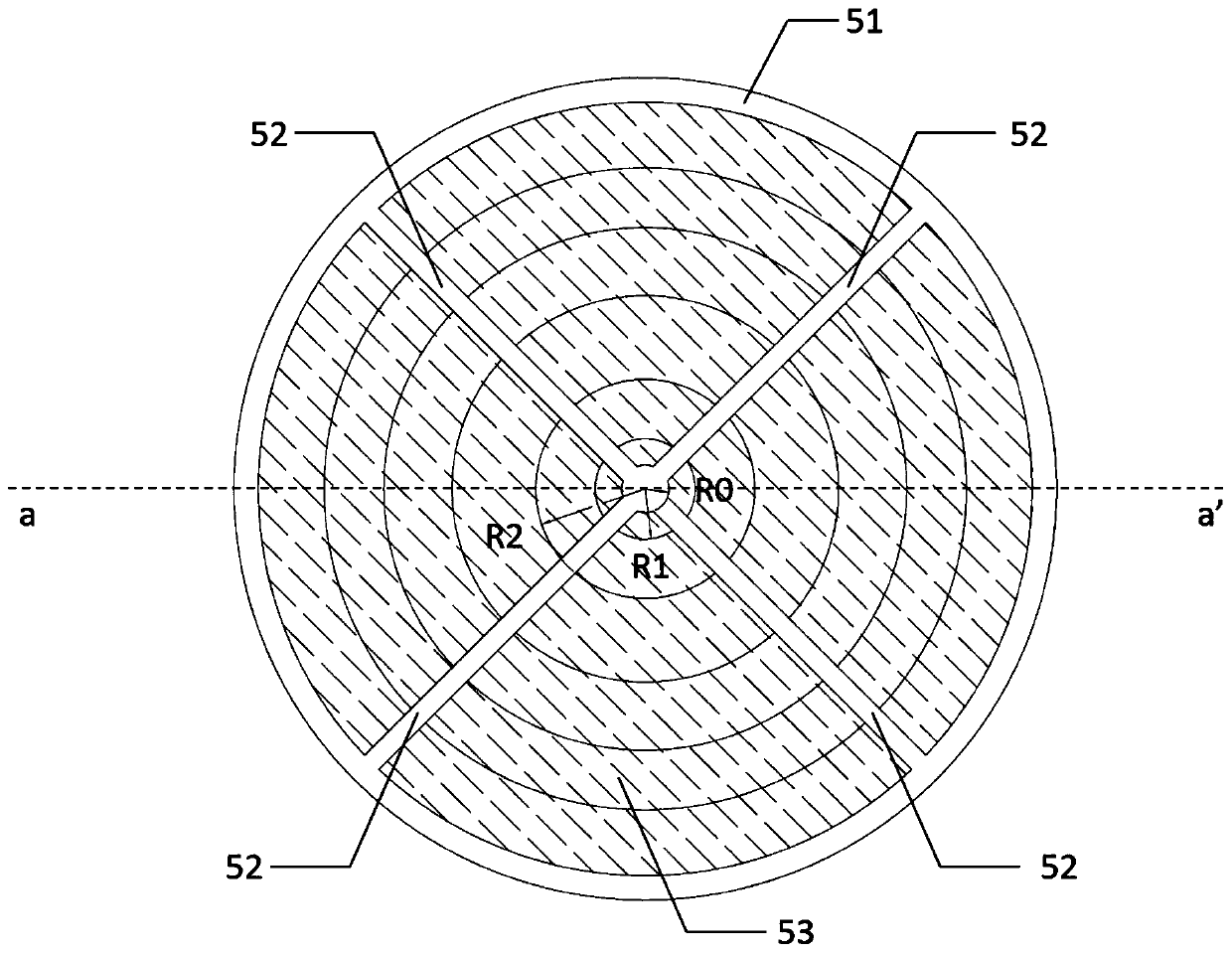

[0057] Such as figure 1 As shown, a molecular sieve tank with a diameter of 2m and a height of 4m, the molecular sieve tank includes a tank body, the tank body is provided with a process gas inlet valve 1 at the top of the tank body and a process gas outlet valve 8 at the bottom of the tank body, the tank body The top is provided with a pressure relief pipeline 2 connected to the pressure relief valve, and 8 plasma torches 9 ( figure 1 Not all are drawn in), the plasma torch 9 is a straight-line plasma torch, and is respectively connected with the corresponding working gas pipeline 7, and the plasma torch 9 is installed on the tank body through the flange, and the working gas is hydrogen with a volume content of 87%. and hydrogen-rich gas with a volume content of 13% carbon monoxide; the inside of the tank is provided with a gas distribution plate 5, a molecular sieve bed 4 and a wire mesh 3, the molecular sieve bed 4 is located above the gas distribution plate 5, and the wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com