Supporting structure and supporting method for limiting horizontal displacement of steep dip phyllite tunnel

A technology of horizontal displacement and support structure, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve obvious effects, prevent large deformation from continuing to develop, and facilitate popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

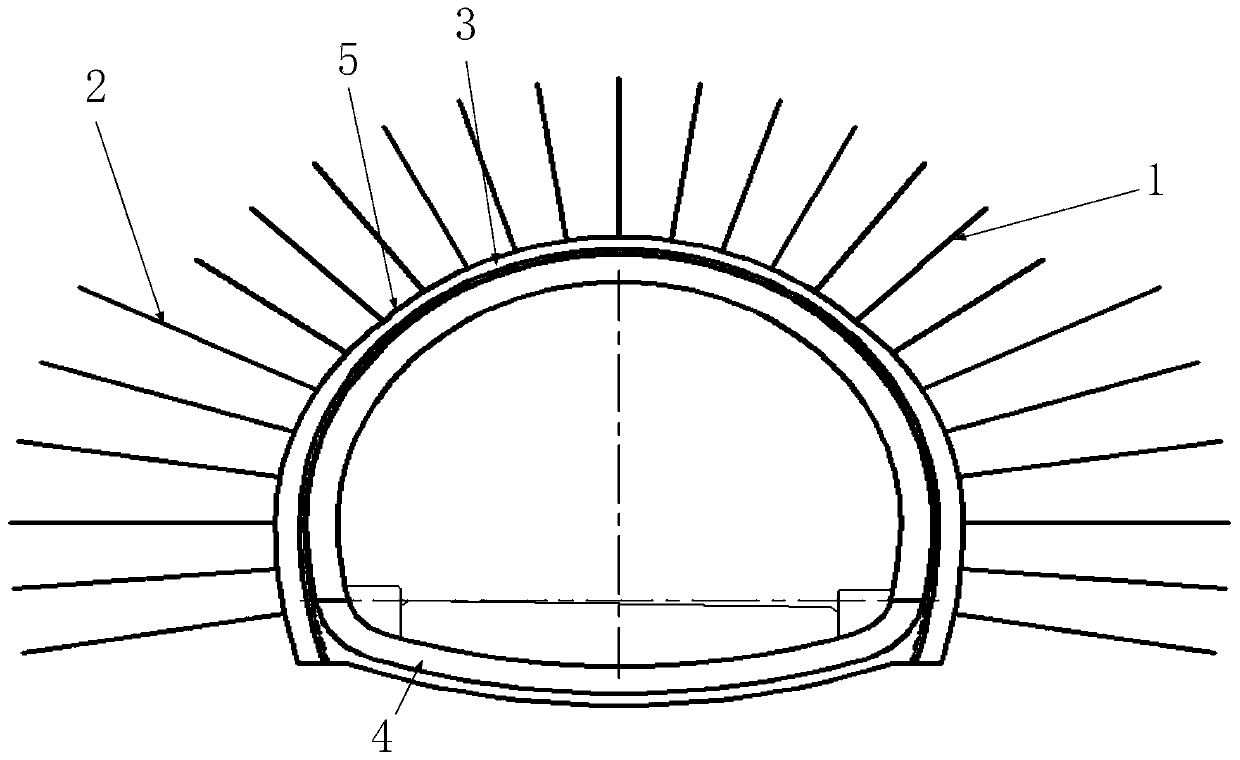

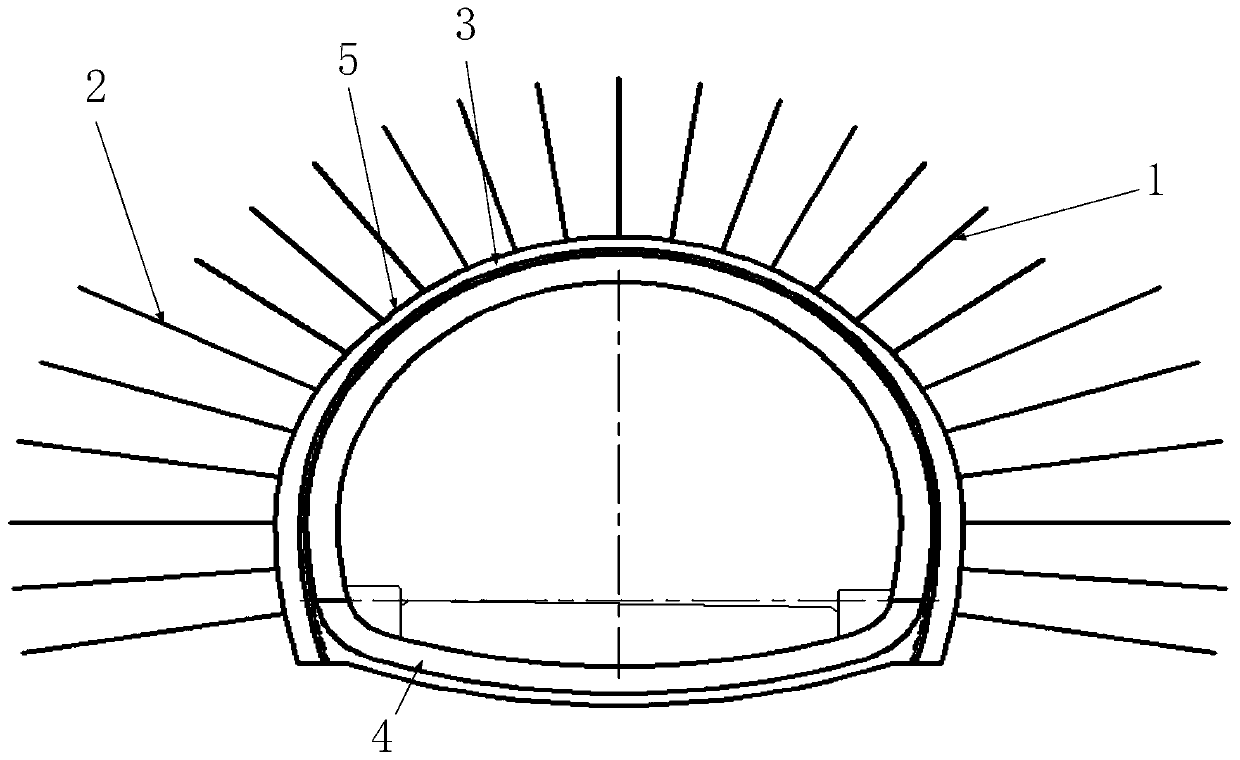

[0029] Such as figure 1 A support structure for limiting the horizontal displacement of a steeply inclined phyllite tunnel is shown, including a tunnel body, primary support 5 located in the tunnel body, and secondary lining 4. The tunnel body includes a vault and a side wall. It is characterized in that the tunnel body reserves a deformation amount 3, and the width of the deformation amount 3 at the side wall is greater than that at the vault; it also includes the anchor rod 1 arranged at the vault, the anchor rod 1 arranged at the side wall The anchor pipe 2, the anchor rod 1 and the anchor pipe 2 are all anchored into the surrounding rock.

Embodiment 2

[0031] Such as figure 1 A support structure for limiting the horizontal displacement of a steeply inclined phyllite tunnel is shown. On the basis of Embodiment 1, the length of the anchor pipe 2 is greater than the length of the anchor rod 1 . Several anchor pipes 2 are distributed in a quincunx shape at the side wall, and the distance between two adjacent anchor pipes 2 is 1m. The secondary lining 4 is a reinforced concrete structure. The initial support 5 includes a steel mesh and a steel frame; the steel mesh is a double-layer steel mesh; the steel frame is an I-beam, and the steel frame includes a locking foot anchor pipe.

Embodiment 3

[0033] A support method for limiting the horizontal displacement of a steeply inclined phyllite tunnel:

[0034] (1) Increase the reserved deformation of the tunnel. The reserved deformation adopts unequal thickness and width. The reserved deformation of the vault is small, and the reserved deformation of the side wall (especially at the upper and lower steps) is increased. The deformation of the constructed section is determined so that the reserved deformation matches the initial support deformation.

[0035] (2) The steel mesh adopts double layers Reinforced mesh, spacing 20cm×20cm. For the anchor rods of the weakened vault system, the distance between the anchor rods at the top shall be determined according to the lower limit value of the tunnel code; Small conduits, 1m x 1m apart, arranged in a quincunx shape.

[0036] (3) The initial support steel frame adopts I18 or I20 I-steel, and the I-steel strengthens the locking feet of the steel frame to release and resist t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com