A spherical turbine housing and turbopump for liquid rocket engines

A liquid rocket and turbine casing technology, which is applied to rocket engine devices, liquid fuel engines, and parts of pumping devices for elastic fluids, etc., can solve problems such as temperature gradient changes, reduce temperature gradients, and improve performance. force and reduce the risk of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

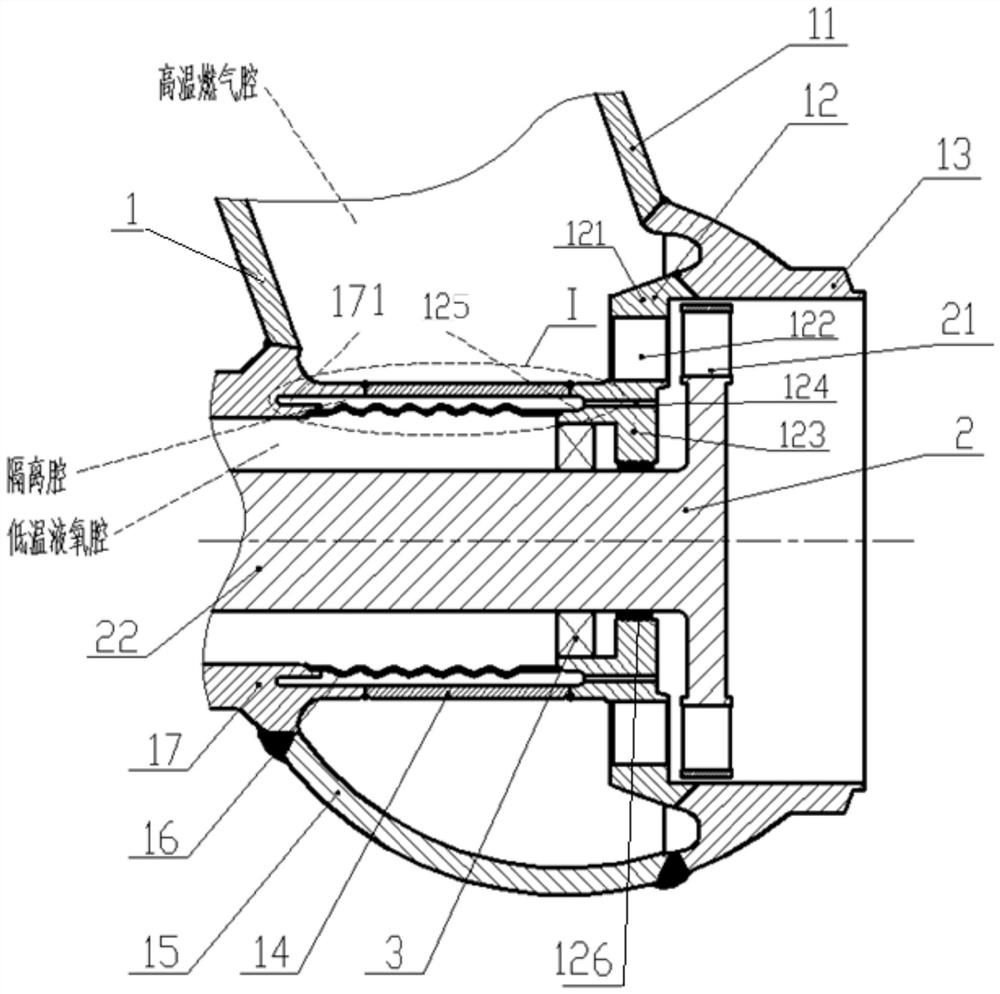

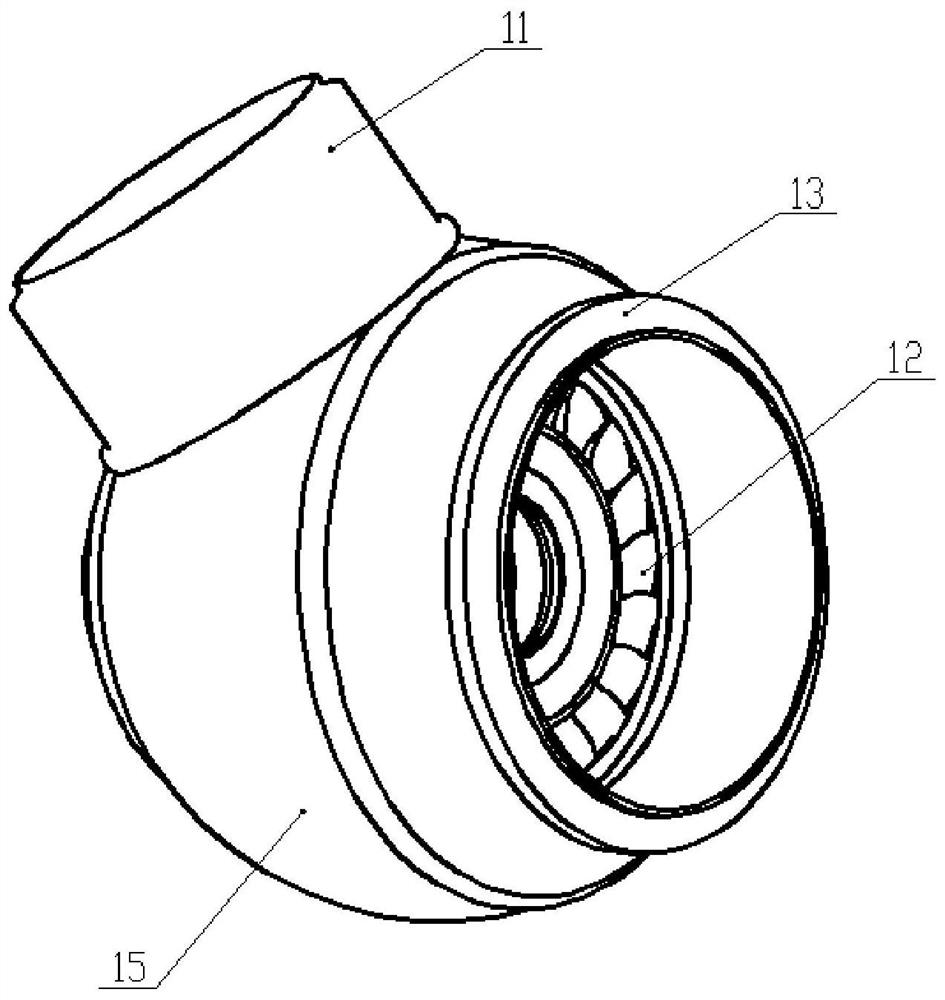

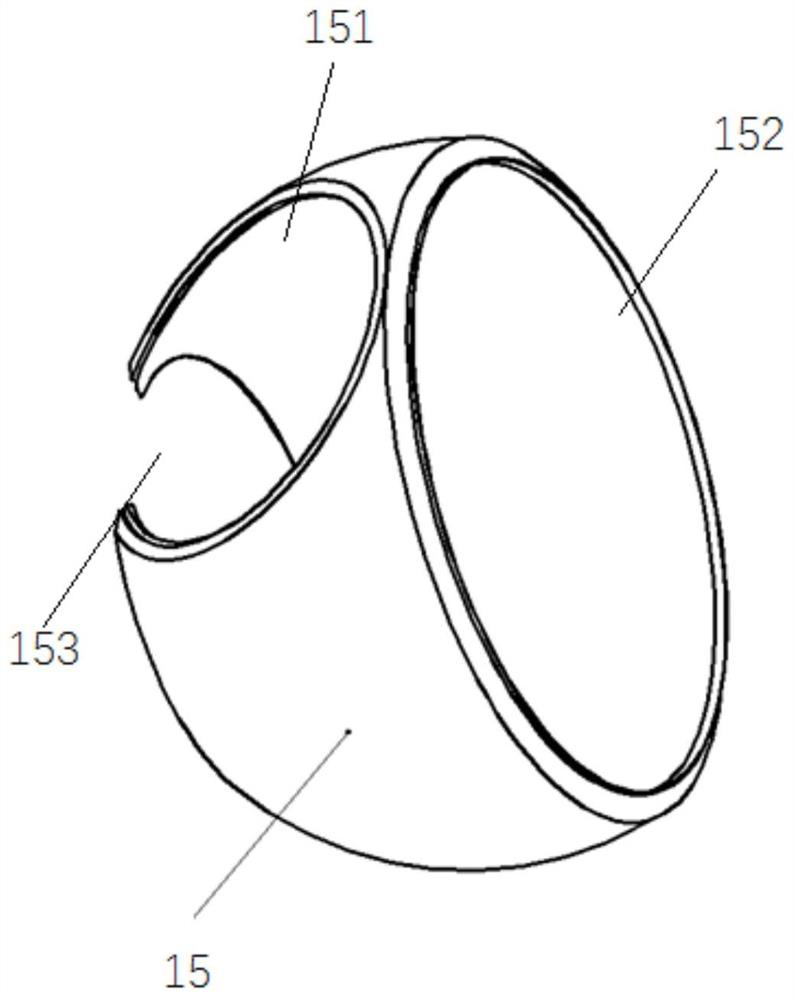

[0026] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention optimizes the structure of the turbine casing, on the one hand, rationally designs the temperature difference stress and deformation of the components to ensure the safe and reliable operation of the turbine pump; , Reliable work under high pressure environment.

[0028] like figure 1 As shown, the liquid rocket engine turbopump provided by the present invention comprises a spherical turbine casing 1, a rotor 2 and a turbine end bearing 3, and the rotor 2 includes two parts of a disc 21 and a rotating shaft 22, both of which are integrally machined, and the rotor 2 The turbine end bearing 3 is connected to the inner surface of the turbine housing. Specifically, the rotating shaft 22 is arranged in the cavity of the connecting sleeve 17, the bellows 16 and the inner ring body 123 through the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com