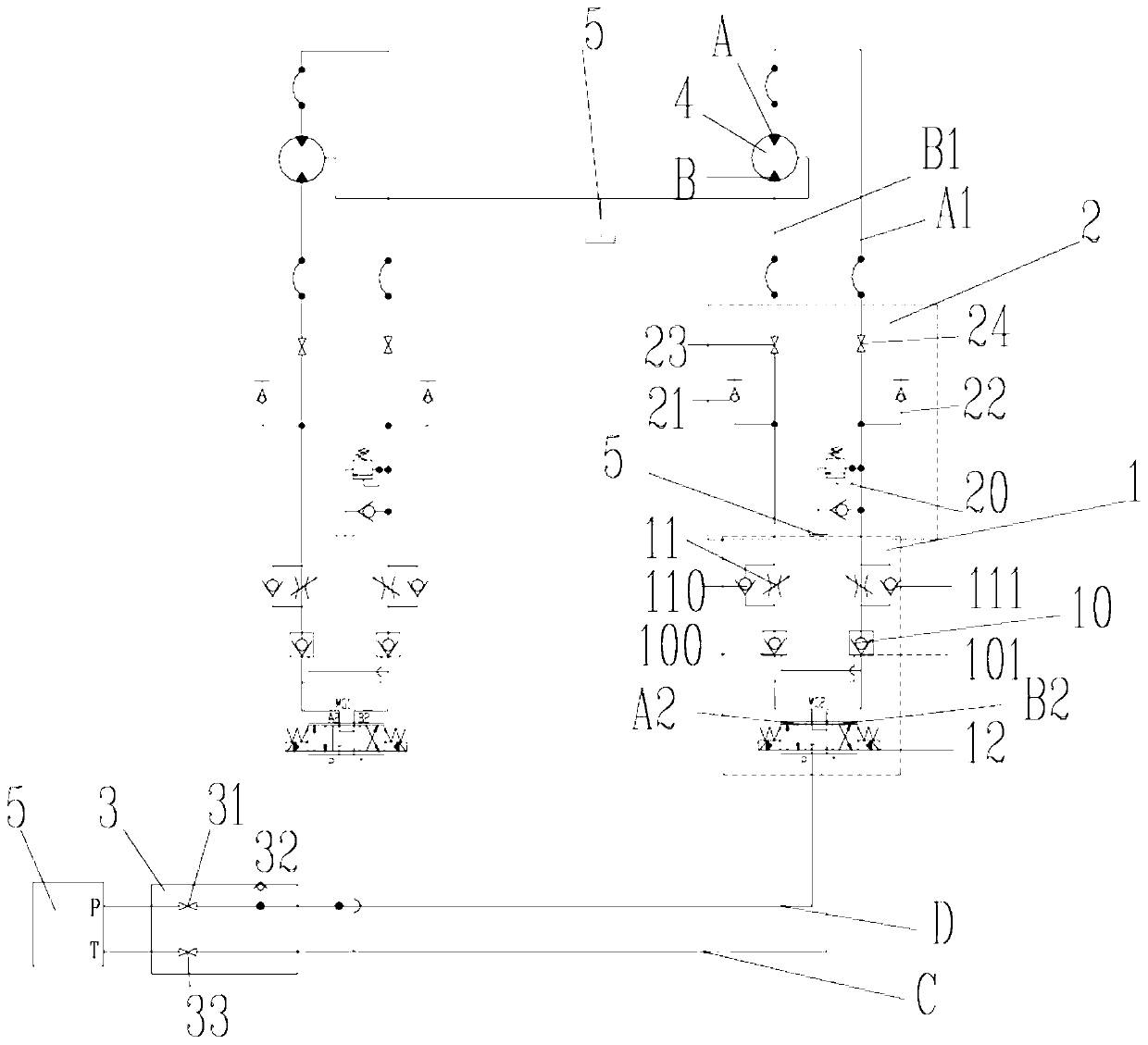

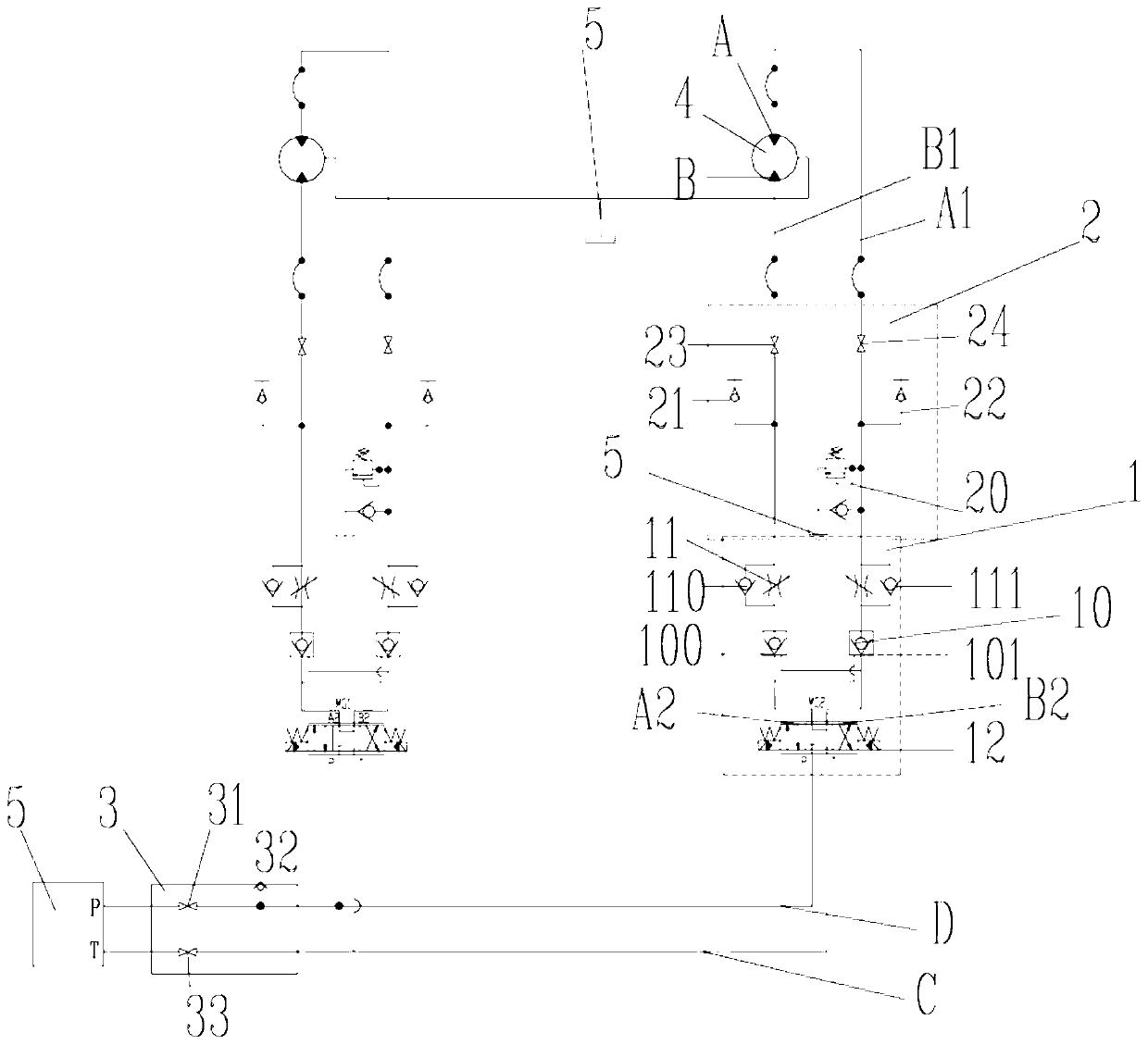

Hydraulic control system for stacking horizontal suction cup translation hydraulic motor device

A hydraulic control system and hydraulic motor technology, applied in the direction of fluid pressure actuation devices, servo motors, servo motor components, etc., can solve problems such as stacking failure, and achieve the effect of improving synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0035] The main oil return line C communicates with the oil supply line A1 through the proportional reversing valve 12, and the main oil supply line D communicates with the oil return line B1 through the proportional reversing valve 12. The two sets of lines can both output oil Oil can also be input, two groups of proportional reversing valves 12, superimposed hydraulic control check valve 10, superimposed double one-way throttle valve 11, cooperate to control the rising and falling speed of two groups of hydraulic motors 4 and two groups of hydraulic pressure The balance between the motors, the balance valve 20, the first pressure measuring joint 21, the second pressure measuring joint 22, the first high pressure ball valve 23, the second high pressure ball valve 24, the high pressure ball valve 31, the third pressure measuring joint 32, The butterfly valve 33 controls the hydraulic motor 4 as an auxiliary.

[0036] The two proportional reversing valves 12 give an electric si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com