Jacket type energy-saving refrigeration house

An energy-saving, jacket-type technology, used in coolers, refrigerated rooms, household refrigeration devices, etc., can solve the problems of increasing heat load, environmental heat load, and compressor return gas with liquid, so as to improve heat exchange efficiency , The effect of reducing forced convection and reducing temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

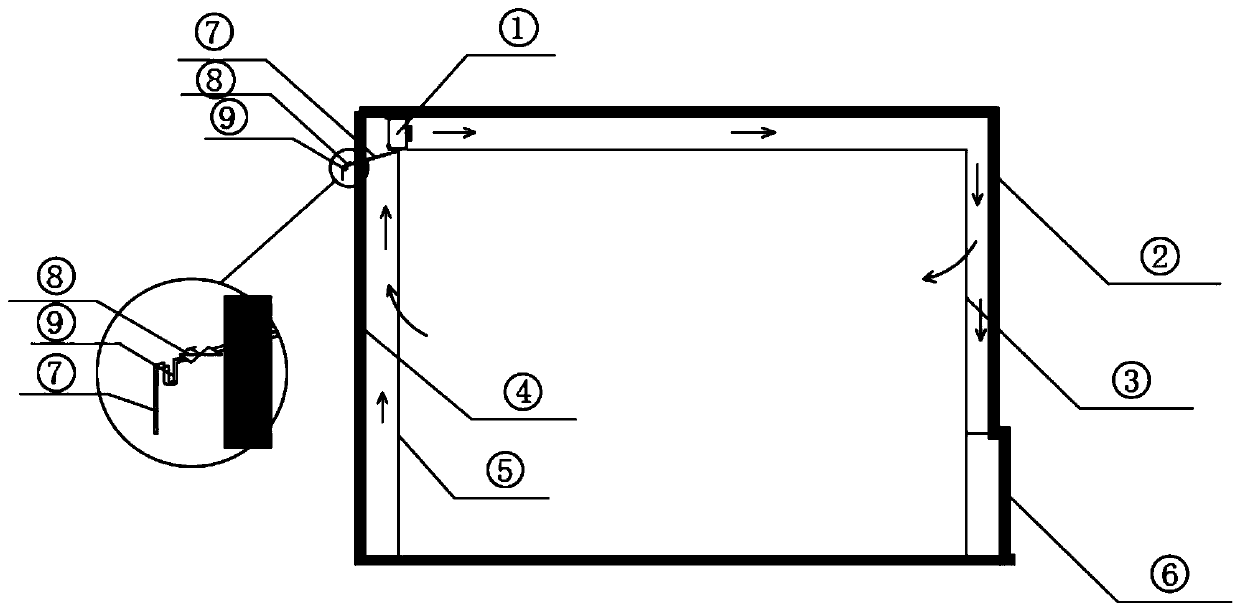

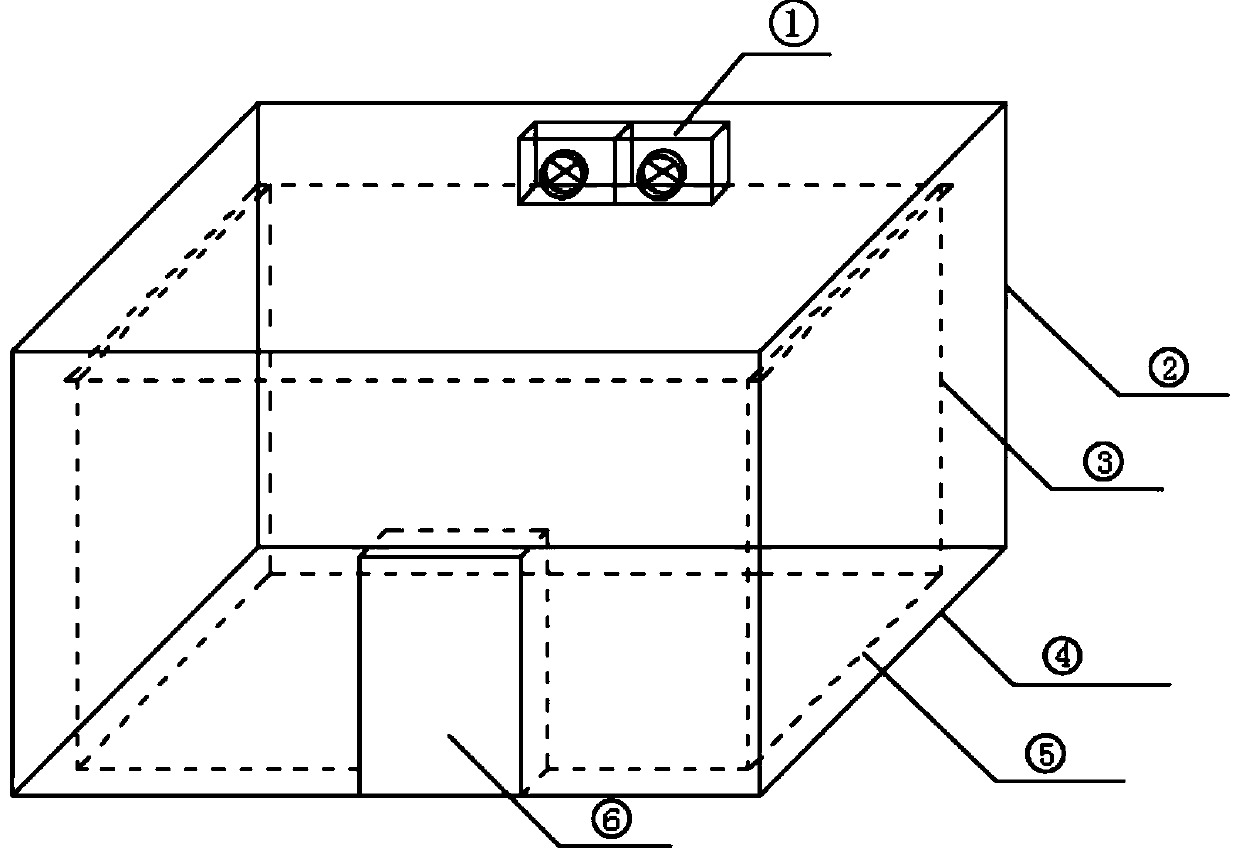

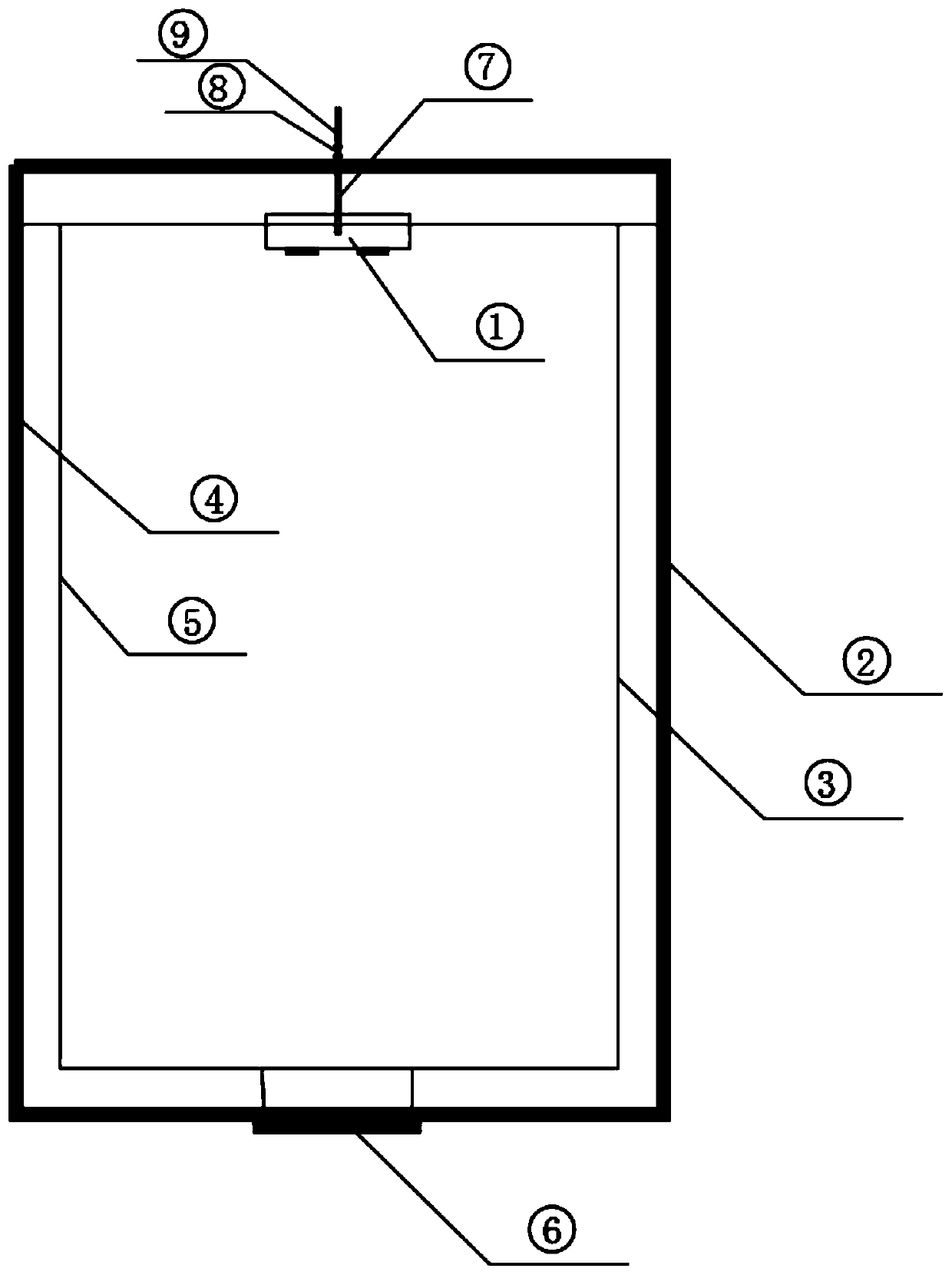

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] like Figure 1-4 As shown, a jacketed energy-saving cold storage of the present invention, the cold storage system includes a mother storage system and a sub-storage system. The main warehouse system mainly refers to the cavity surrounded by the thermal insulation structure layer 2 of the cold storage system, while the sub-warehouse system rebuilds a jacket with metal materials with good thermal conductivity inside the thermal insulation structure layer. There is a certain gap between the storage boards, and the ground layer does not need to consider the gap, that is, the actual jacket is built as a pentahedral sub-storey heat conduction structure 3, and the evaporator 1 (cooling fan) of the refrigeration system is installed between the parent storage system and the sub-storey system Formed inside of the sandwich.

[0018] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com