A mobile water source type temperature-controllable pharmaceutical reaction device

A reaction device and water source technology, which is applied in the field of flow water source temperature-controllable pharmaceutical reaction devices, can solve the problems of low cooling or heating efficiency, high-grade energy waste, and low energy efficiency of the system, and achieve a stable compression ratio curve and high energy efficiency. Effect of small fluctuations in utilization rate, evaporating temperature or condensing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which presently preferred embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for thoroughness and completeness, and will fully convey the scope of the invention. communicated to technical staff.

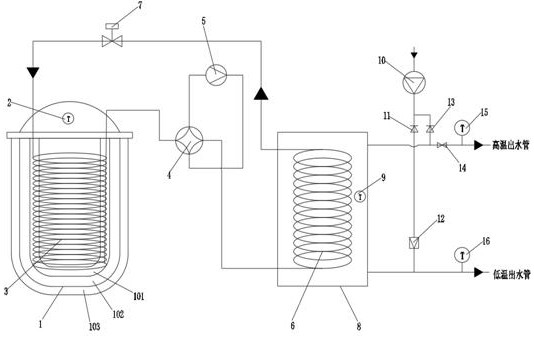

[0041] Such as Figure 1-3Shown is a flowing water source type temperature-controllable pharmaceutical reaction device, including a pharmaceutical reaction kettle 1, a first phase-change heat exchanger 3, a second phase-change heat exchanger 6, an electronic expansion valve 7, and a four-way reversing valve 4 And frequency conversion compressor 5, medicine reaction kettle 1 is used as the container of pharmaceutical reaction, and medicine reaction kettle 1 adopts three interlayers to set, inner int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com