High-voltage direct-current urban rail transit traction power supply system

A technology of urban rail transit and traction power supply system, which is applied in the direction of load balance, electrical components, power lines, etc. in the DC network, to achieve the effect of small footprint, solve the problems of track potential and stray current, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

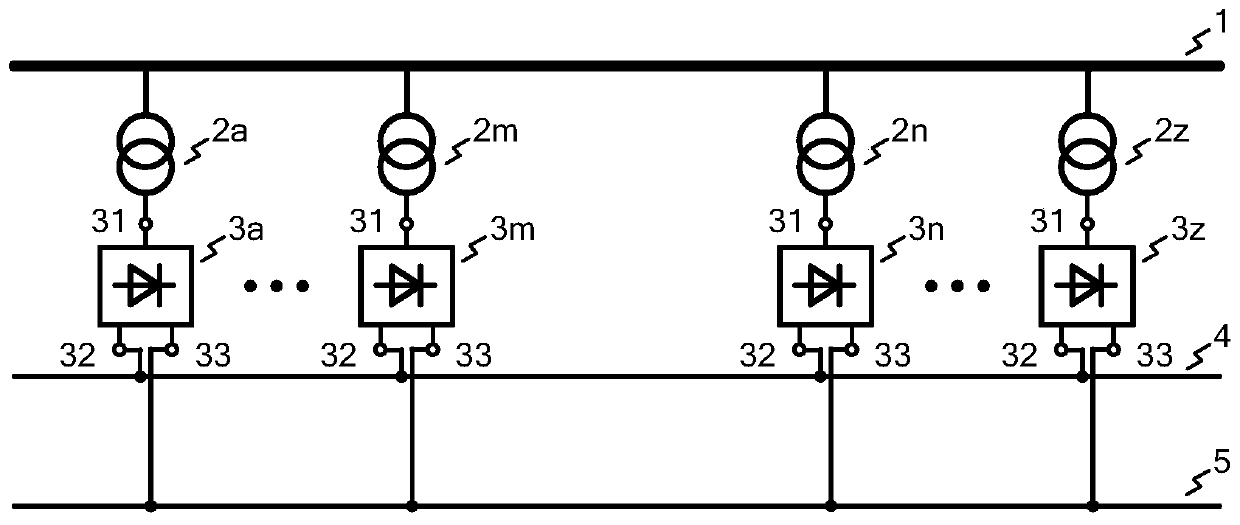

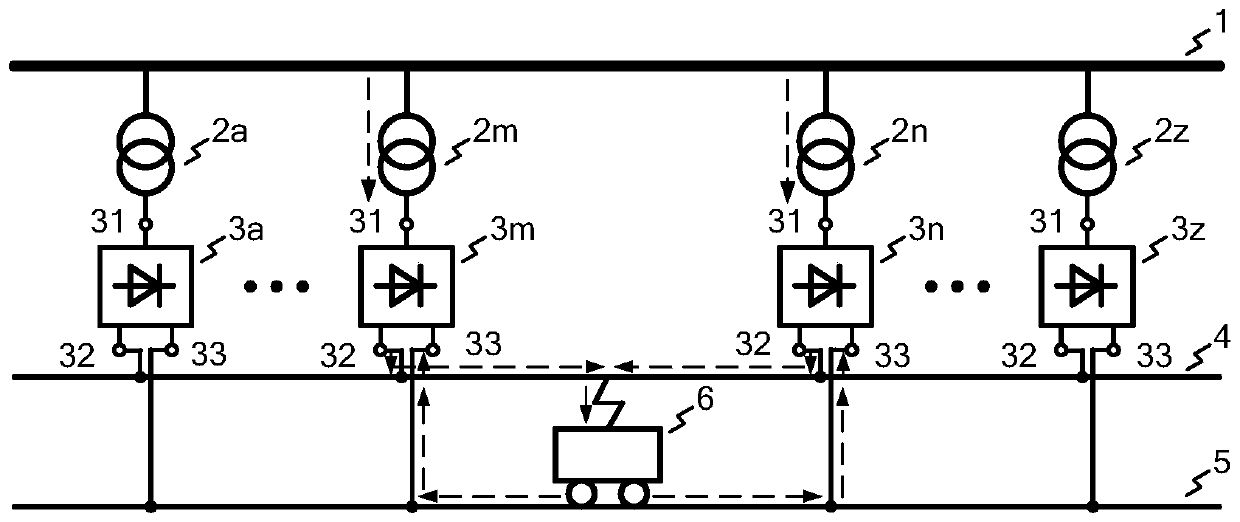

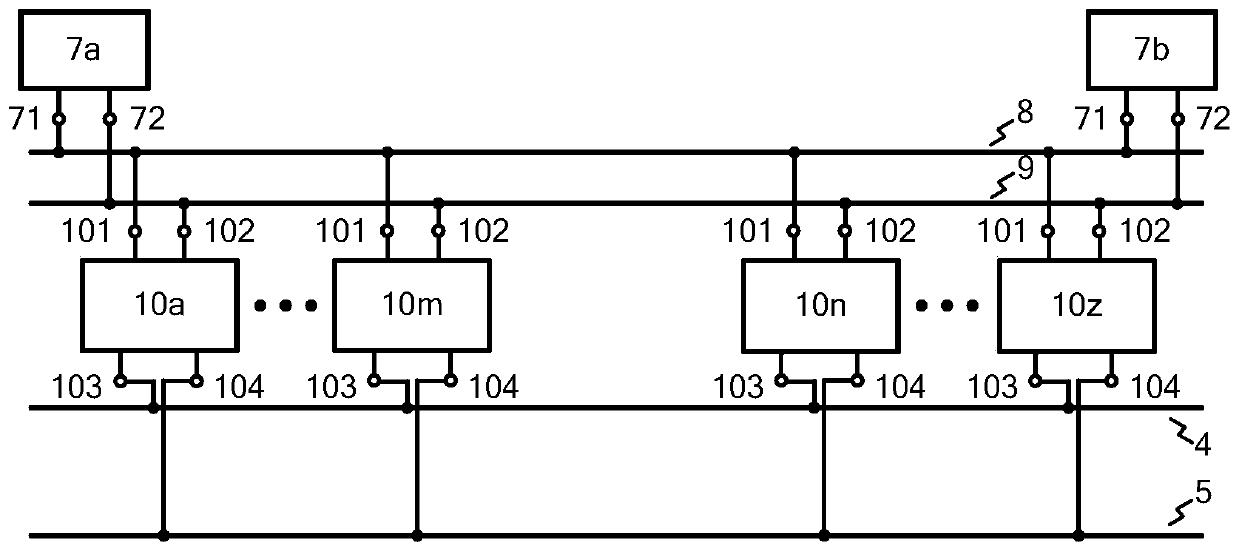

[0059] The existing urban rail transit traction power supply system scheme shown in Figure 1 (a) and (b) includes: a high-voltage AC bus 1, a phase-shifting transformer 2, and a multi-pulse rectifier device 3, which is responsible for distributing electric energy to the train 6 Net (or the third rail) 4 and walking rail 5. The phase-shifting transformer 2 and the multi-pulse rectification device 3 are typical solutions of the traction substation in the existing urban rail transit traction power supply system. Now the train runs between the phase-shifting transformer 2m (or multi-pulse rectification device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com