An automatic glue coating and pressing pad device for bottle cap production

A bottle cap and gluing technology, applied in applications, household appliances, household components, etc., can solve the problems that the stamping device is easy to press into the hands of workers, low production efficiency, and troublesome operation, so as to improve labor safety and improve The effect of increasing production efficiency and reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

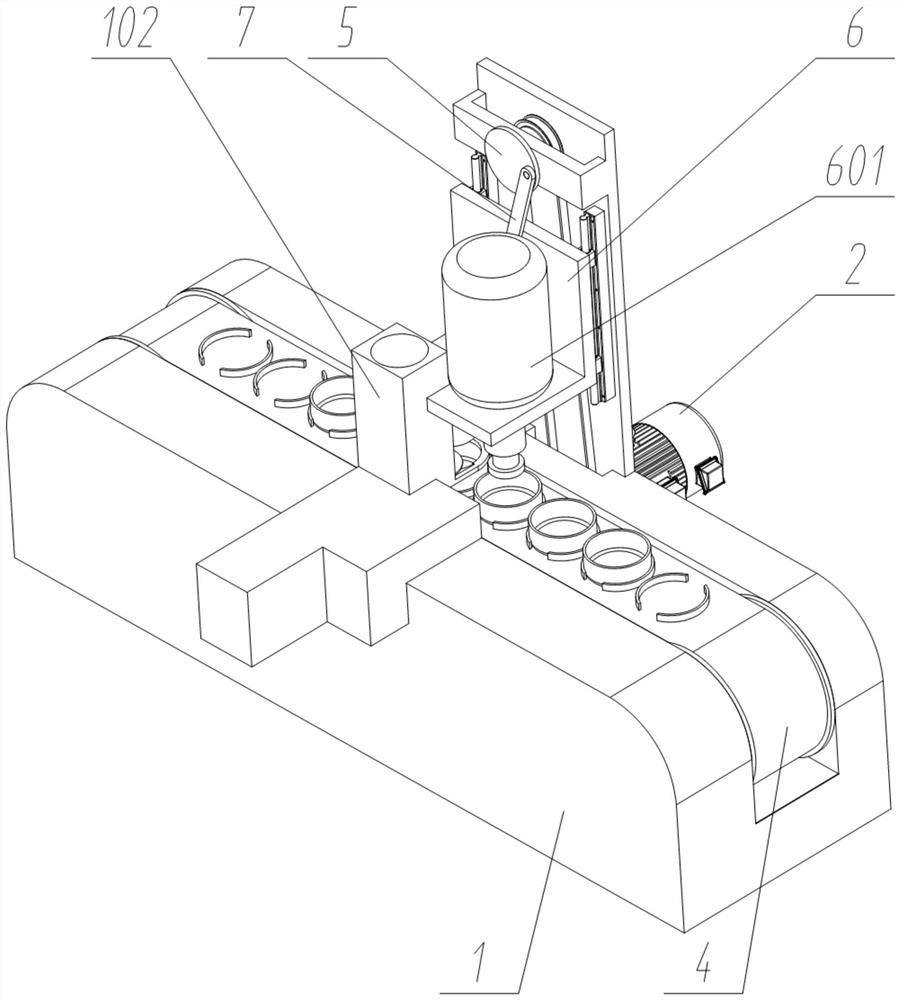

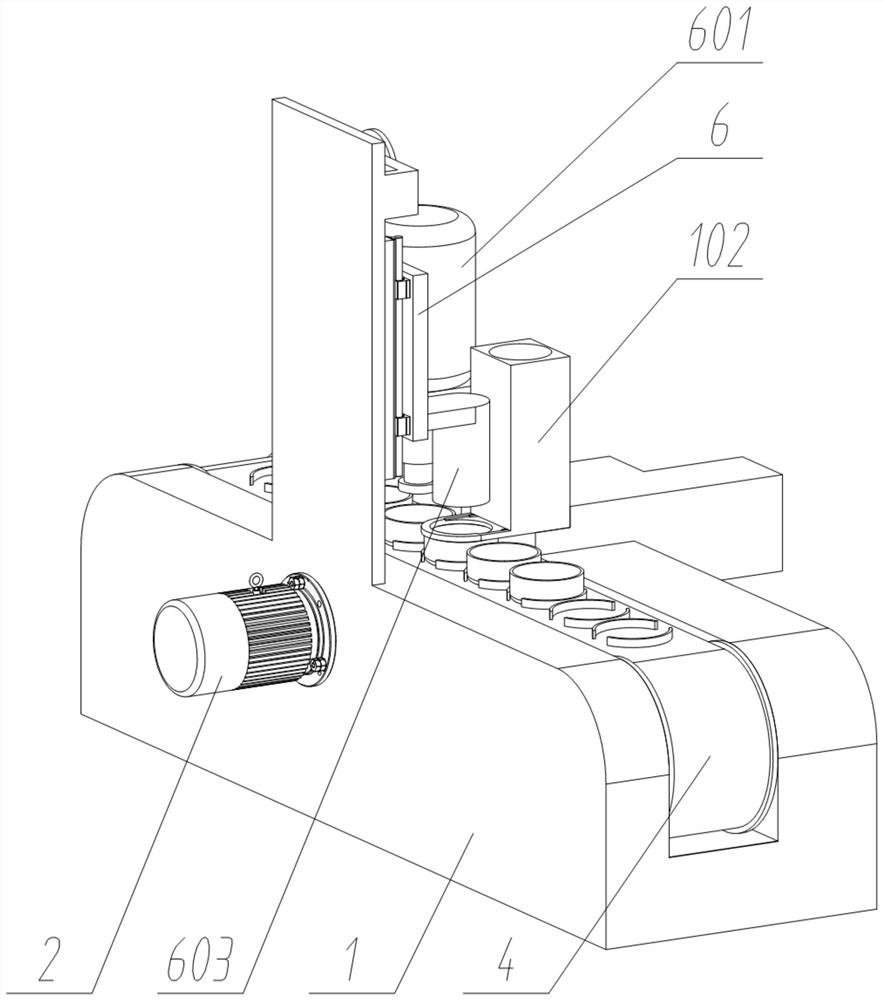

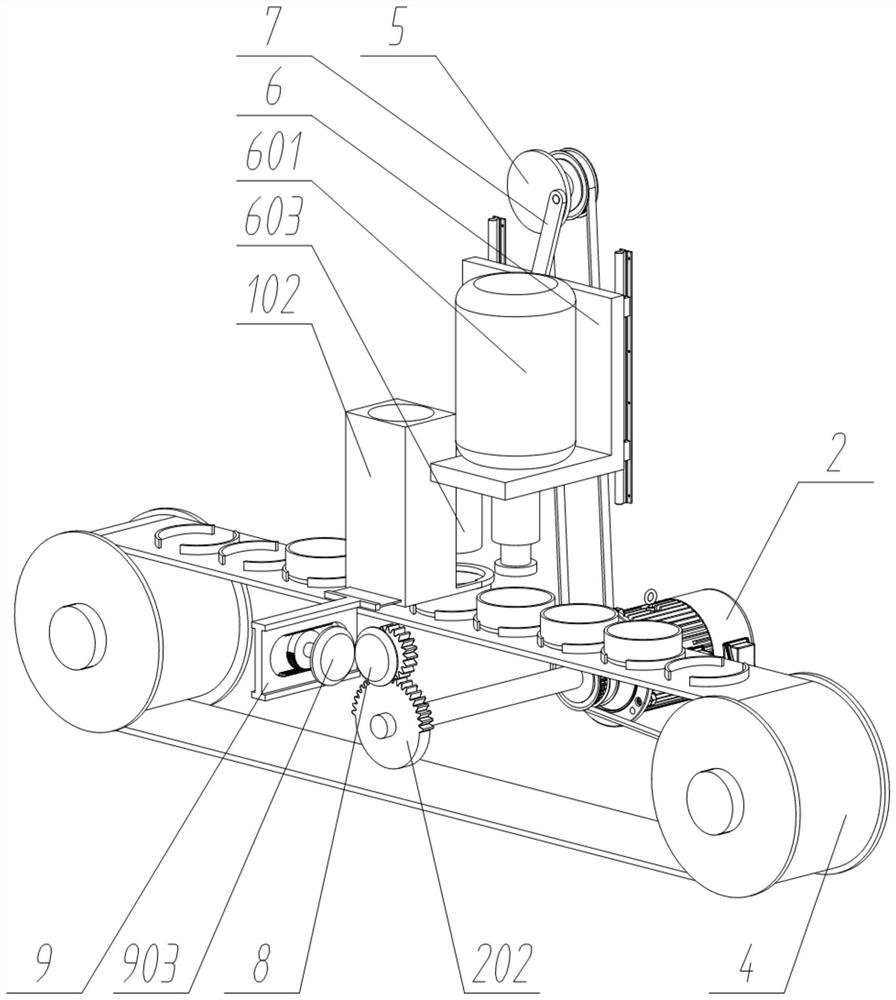

[0031] see Figure 1 to Figure 9, an embodiment provided by the present invention: an automatic gluing and pressing pad device for bottle cap production, including a main body 1; the main body 1 also includes a guide rail slider pair 101, and two sets of guide rails are installed on the upper front side of the main body 1 The slider pair 101, the sliding pallet 6 is slidingly connected with the main body 1 through the guide rail slider pair 101, and the guide rail slider pair 101 guides the sliding pallet 6; the lower part of the rear side of the main body 1 is equipped with a group of motors 2 through bolts; the motor 2 Also includes driving pulley 201, two groups of driving pulleys 201 are connected by keys on the output shaft of motor 2, feeding intermediate transmission shaft 3 and flywheel 5 are connected with driving pulley 201 through synchronous transmission belt transmission mechanism respectively, motor 2 The feeding intermediate drive shaft 3 and the flywheel 5 are ...

Embodiment 2

[0034] see Figure 3 to Figure 9 The push pad reciprocating mechanism 9 also includes a sliding block 901, a reciprocating drive gear 902, and a driven bevel gear 903. The main body of the push pad reciprocating mechanism 9 is a sliding block 901, and the middle part of the sliding block 901 has an opening. The tooth bar that is set, the middle part of push pad reciprocating mechanism 9 are rotationally equipped with a group of reciprocating drive gear 902, reciprocating drive gear 902 is an incomplete gear with only half teeth, and a group of driven bevel gear 903 is coaxially connected to the right end of reciprocating drive gear 902, The reciprocating drive gear 902 is meshed with the push pad intermediate transmission shaft 8 through the driven bevel gear 903 to jointly form a bevel gear transmission mechanism.

[0035] The push pad reciprocating mechanism 9 also includes a push pad 904, and a group of push pads 904 is connected to the left side of the sliding block 901. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com